Mold inner wall spraying system for die casting equipment

A technology in the mold and equipment, applied in the direction of the injection device, etc., can solve the problems of spraying on the inner wall of the mold core and difficulty in atomizing the nozzle, and achieve the effect of rapid spraying and increased spraying range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

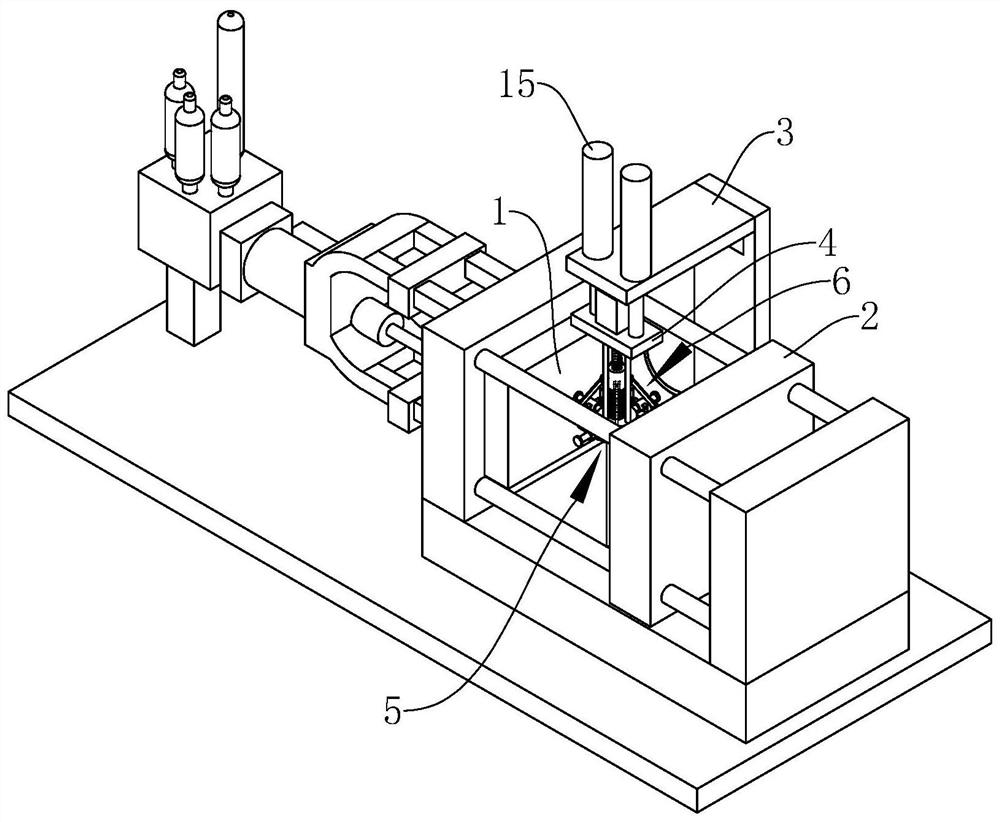

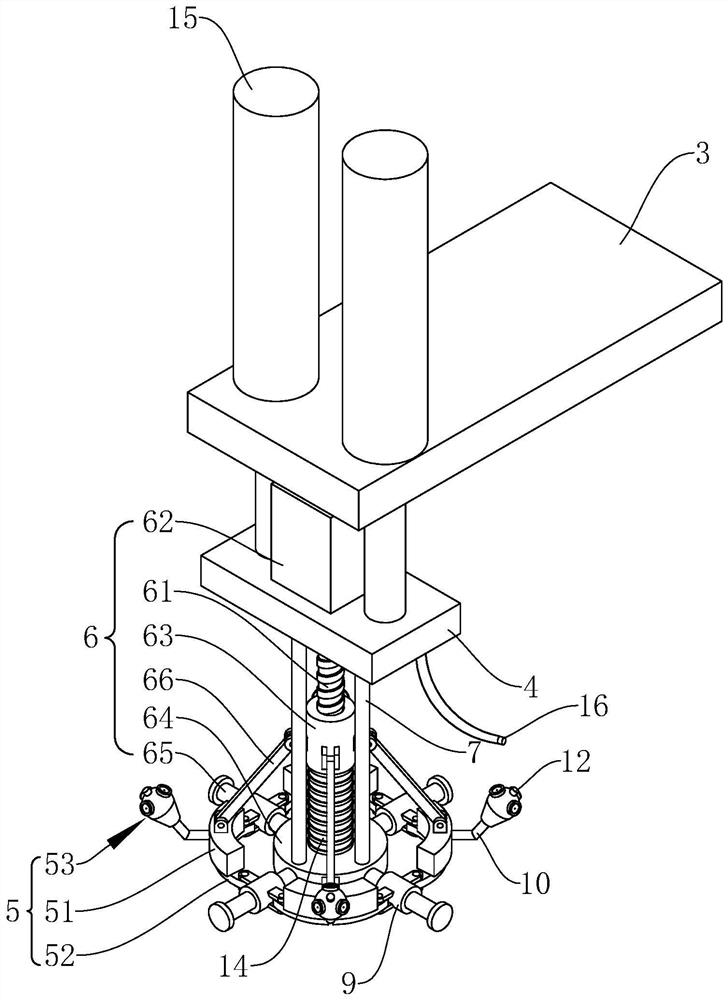

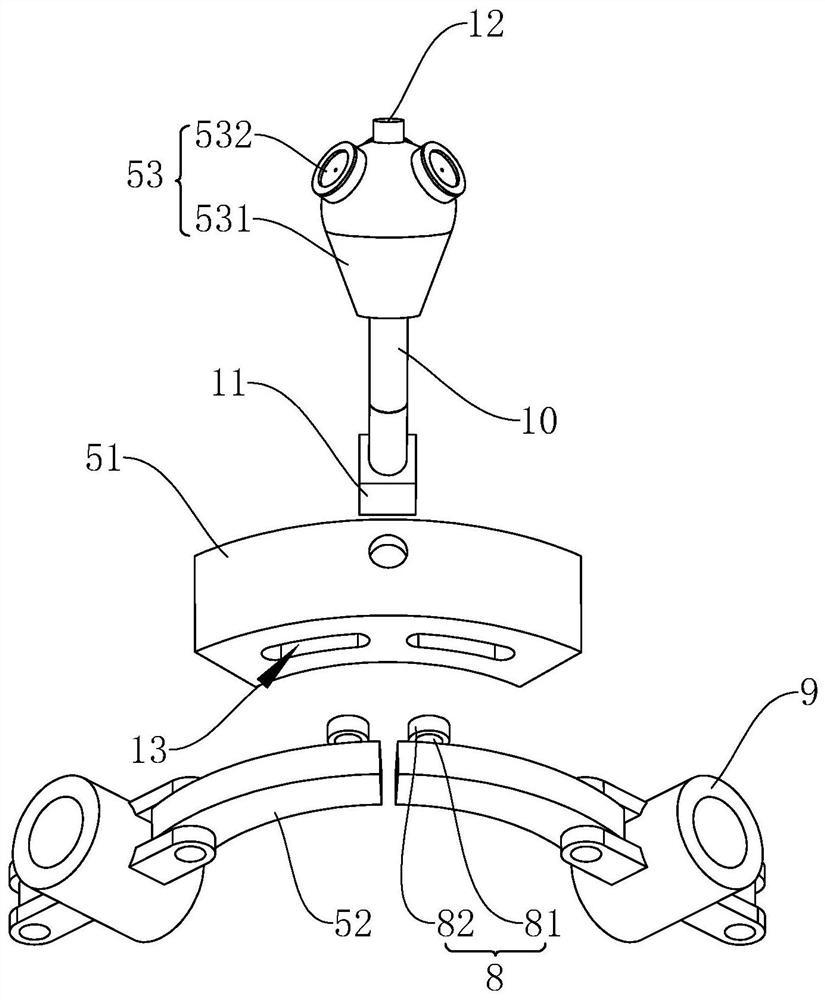

[0035] Attached to the following Figure 1-3 This application will be described in further detail.

[0036] The embodiment of the present application discloses a mold inner wall spraying system of a die casting equipment. refer to figure 1 and figure 2 , the mold inner wall spraying system of the die-casting equipment includes a support plate 3 located above the movable mold core 1 and the static mold core 2. The static mold core 2 is fixedly erected on the die-casting equipment through the mold base, and the movable mold core 1 passes through the mold base. The sliding is arranged on the die casting equipment, and the movable mold core 1 can slide toward or away from the static mold core 2. The cavity formed after the movable mold core 1 and the static mold core 2 are pressed together is used for injection. The aluminum soup is die-cast as a casting.

[0037] refer to figure 1 and figure 2 , the support plate 3 is fixed above the movable mold core 1 and the static mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com