A method for piercing the lead wire of an aluminum electrolytic capacitor core

A technology of aluminum electrolytic capacitors and core-wrapped leads, applied in capacitor terminals, capacitor parts and other directions, can solve the problems of aluminum foil sparking breakdown, affecting long life, falling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

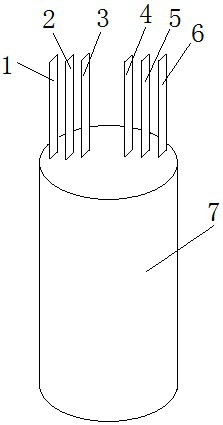

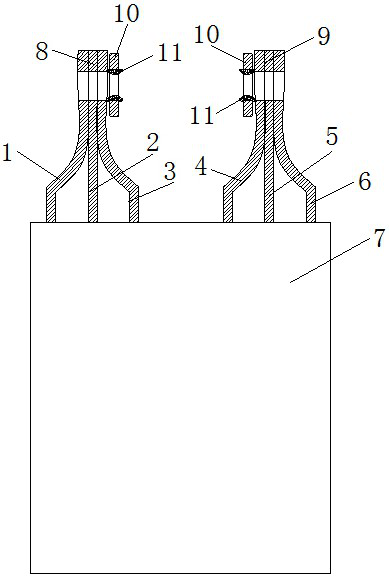

[0029]A method for piercing lead wires of an aluminum electrolytic capacitor core. The method adopts ultrasonic welding pretreatment and fusion to pretreat the lead wires before piercing, and respectively welds the ends of multiple pairs of positive lead wires and negative lead wires on the capacitor core pack. Together, this pretreatment method welds multiple pairs of lead wires of the same polarity together by ultrasonic welding. This ultrasonic pretreatment method makes the lead wires of the same polarity in a welded state, respectively forming the positive connecting wire 8 and Negative electrode connecting wire 9; when piercing, each lead wire in the inner circle of the washer forms a single embossed whole, which can effectively prevent the embossed from falling off; specifically, the pretreatment method for the lead wire puncture of the multi-pair lead core package of the aluminum electrolytic capacitor includes: The following steps are as follows: in the aluminum electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com