Novel paint cup

A paint cup, a new type of technology, applied in decorative arts, painting tools, etc., can solve the problems of being unable to tighten the palm and the cup body, unable to maintain the adjustment position stably, and achieve the effect of safe painting from the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

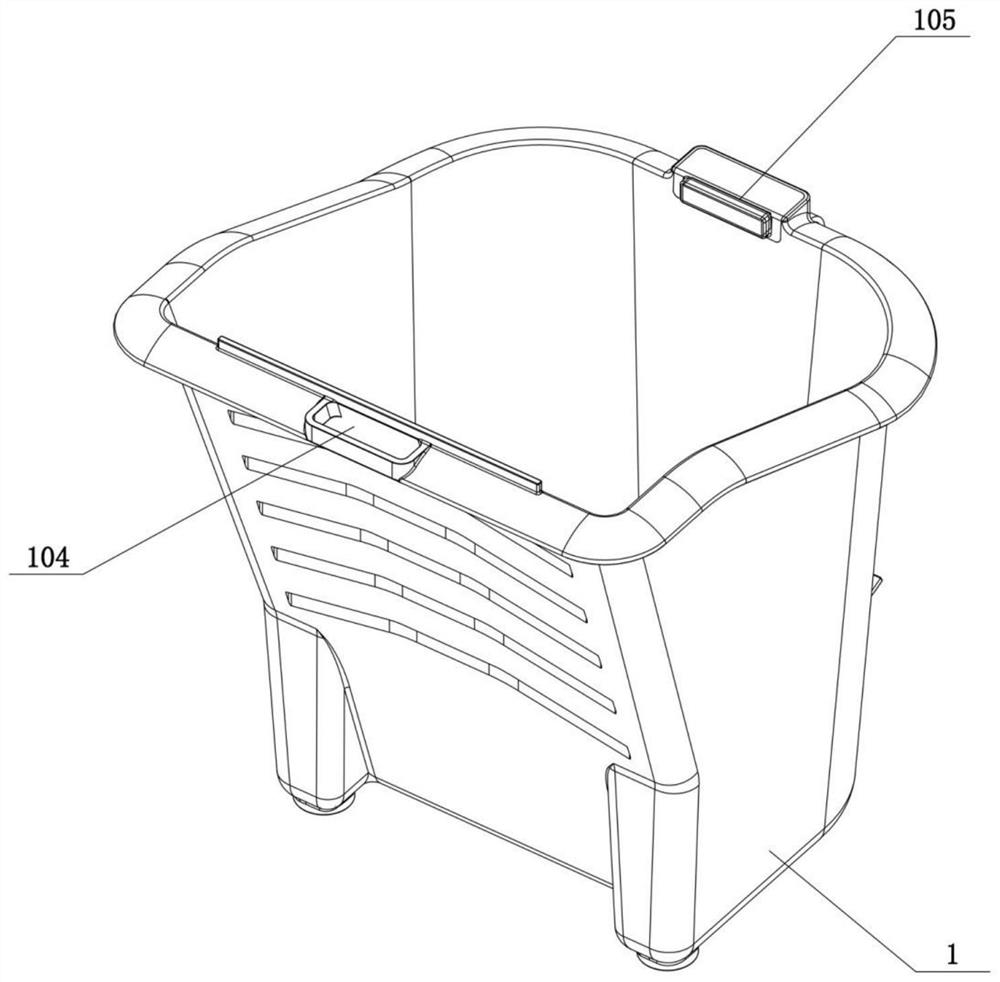

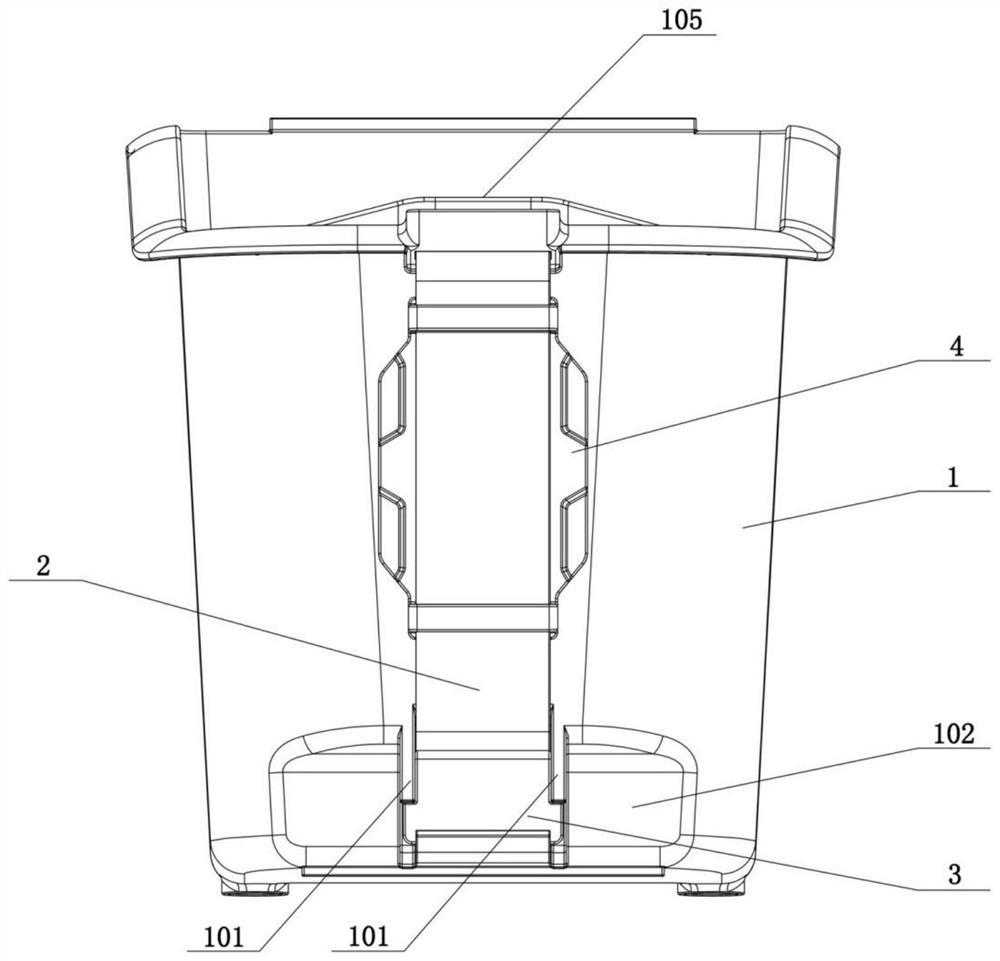

[0034] Such as Figure 1 to Figure 3As shown, a new type of paint cup, the same as the prior art, it includes a cup body 1, the rear side of the cup body 1 is provided with a handle, especially, the handle is a flexible handle, which includes one end as a fixed end and the other end The adjustment belt 2 is a free end, and the fixed end of the adjustment belt 2 is connected with the cup body 1. In addition, a retractable belt mechanism opposite to the adjustment belt 2 is provided on the rear side of the cup body 1, and the retractable belt mechanism is connected with the adjustment belt 2 at the same time. There is a certain distance between the fixed ends of the cup body. This part of the distance is used for inserting the palm of the operator in a posture capable of holding the cup body 1. Here, the palm is defined as the holding hand. The free end of the adjustment belt 2 is self-retractable. One side of the mechanism passes through and extends to the outside of the other ...

Embodiment 2

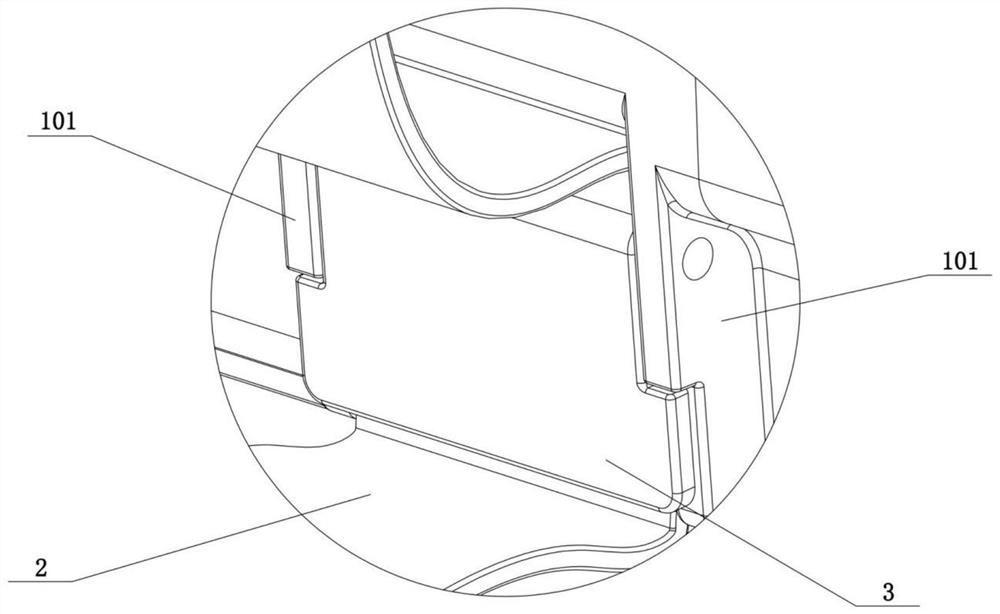

[0036] Such as figure 2 and image 3 As shown, the above-mentioned retractable belt mechanism specifically includes an adjustment block 3, and a boss 101 protruding outward is formed on the cup body 1 located on the left and right sides of the adjustment block 3, and the adjustment block 3 and the boss 101 are connected together. It is connected in a rotatable manner, and when it rotates to a certain angle, it forms a gap with the cup body 1, and the free end of the adjustment belt 2 passes through the gap. When the included angle is 90 degrees, the gap between it and the cup body 1 of the corresponding part reaches the maximum. The operator can use the non-holding hand to pull the adjustment belt 2 to change the adjustment belt 2 at its fixed end and the retractable belt mechanism. The length of the part between, when the holding hand and the cup body 1 are tightly attached, turn the adjustment block 3 in the direction of the cup body 1 to reduce the gap between the adjustm...

Embodiment 3

[0038] Such as Figure 4 As shown, in this embodiment, one of the optimized designs is made on the basis of the above-mentioned embodiment 2, and a plurality of first teeth 301 are arranged on the side of the adjustment block 3 close to the free end or the fixed end of the adjustment belt 2, so that Increase the friction when sliding with the adjustment belt 2, so as to further improve the pressing effect of the adjustment block 3 on the adjustment belt 2 located in the above-mentioned gap after the adjustment of the adjustment belt 2 is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com