Slit airway air brick and production method thereof

A production method and technology of air-permeable bricks, applied in the field of air-permeable bricks, can solve the problems of affecting the ventilation volume of slit airways, narrow airways, blockage, etc., so as to prevent narrowing or even blockage, prevent molten steel from splashing, and ensure air flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

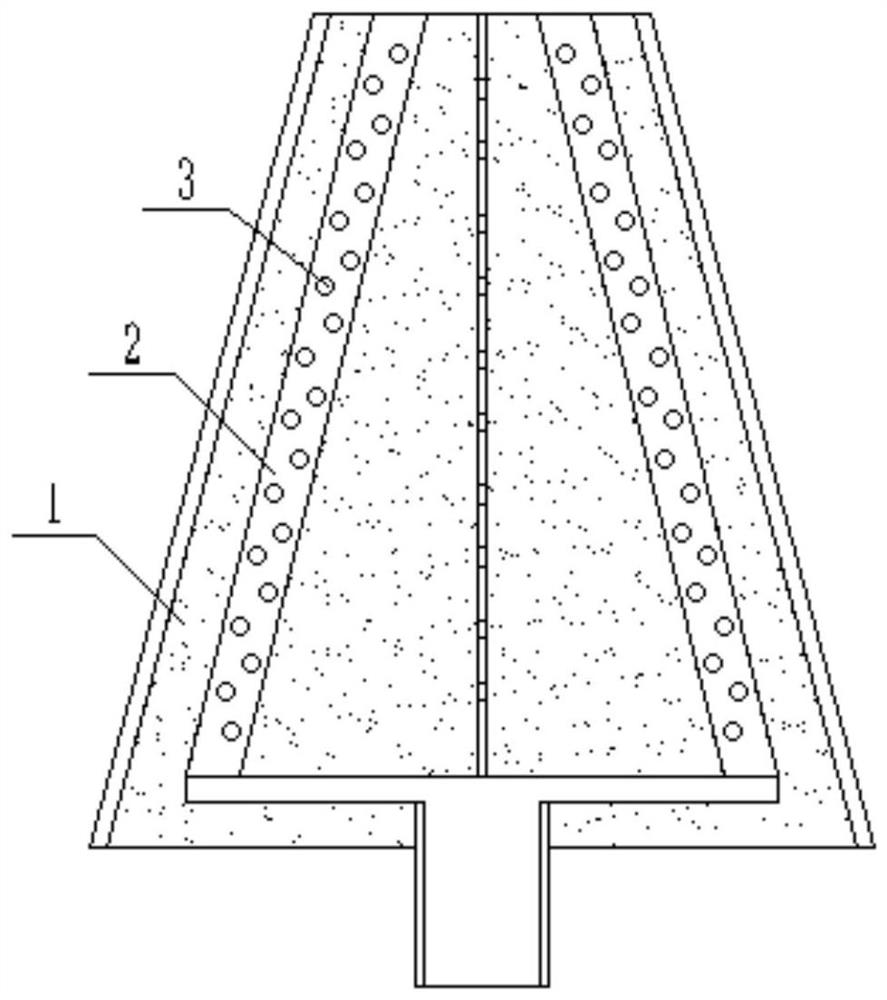

[0035] see Figure 1-Figure 2 As shown, the present invention provides a slit air passage permeable brick, including a brick body 1, a slit air passage 2 is arranged inside the brick body 1, and the slit air passage 2 extends along the axial direction of the brick body 1, and the slit air passage There are multiple passages 2 and they are evenly distributed around the axis of the brick body 1; the inside of the slit air passage 2 is formed with reinforcing columns 3, and there are multiple reinforcement columns 3 that are evenly distributed along the length direction of the slit air passage 2 , two adjacent reinforcing columns 3 are distributed in a staggered manner on both sides of the midline of the width of the slit airway 2 .

[0036] As an optional embodiment, the width dimension of the reinforcement column 3 is one-third of the width dimension of the slit airway 2, which is set in this way, while ensuring the strengthening effect of the reinforcement column 3 on the slit...

Embodiment 2

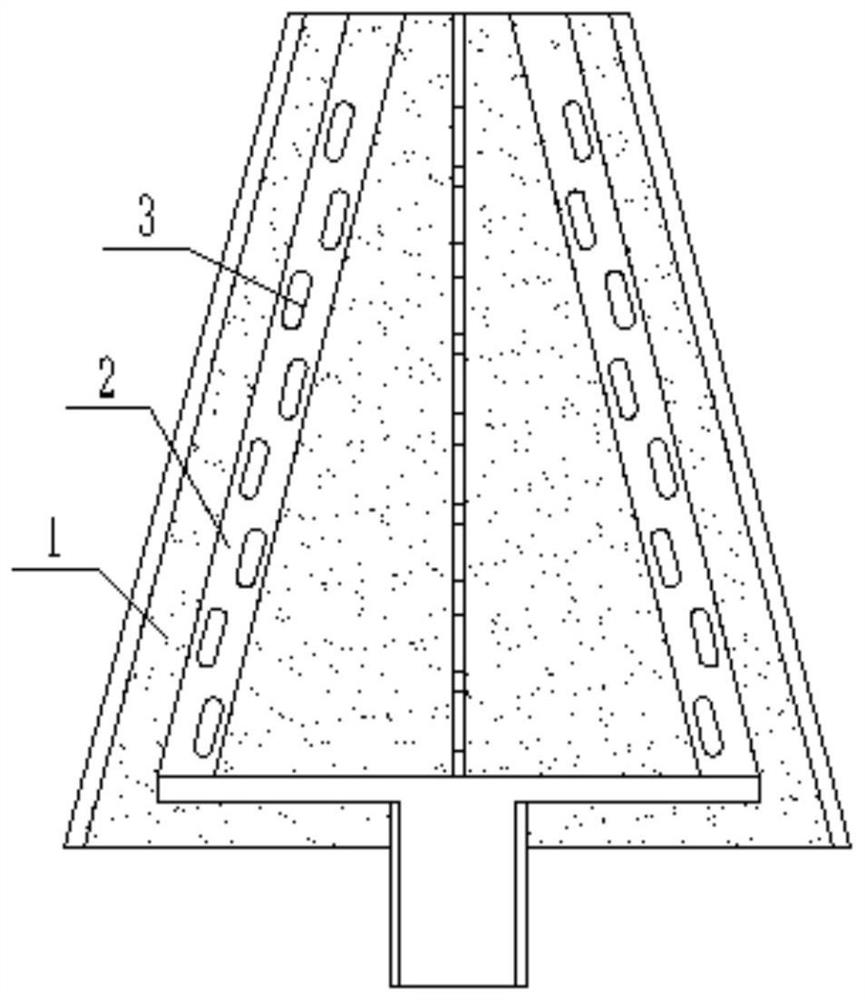

[0052] like Figure 3-Figure 4 As shown, the difference between embodiment two and embodiment one is:

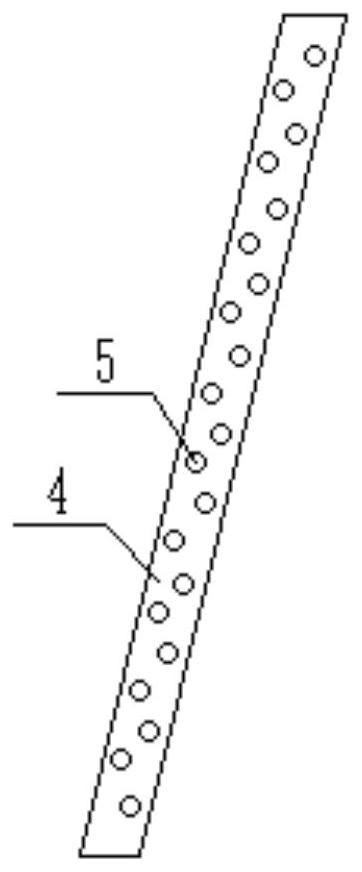

[0053]The cross-section of the reinforcement column 3 is a "waist hole" structure, and the length direction of the reinforcement column 3 is in the same direction as the length direction of the slit air passage 2. Such arrangement can reduce the impact of the reinforcement column 3 on the internal air flow of the slit air passage 2. While obstructing, the strengthening effect of the reinforcing column 3 on the strength of the slit airway 2 can be improved.

[0054] The through-hole 5 is a waist-shaped hole, and the through-hole 5 extends along the length direction of the burnt-out bar 4, so that the cross-section of the formed reinforcement column 3 can be a "waist-shaped hole" structure, and the number of pairs of reinforcement columns 3 can be reduced. While obstructing the airflow inside the slit airway 2, the strengthening effect of the reinforcing column 3 on the stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com