Reagent disc liquid sample adding structure

A reagent plate and liquid technology, which is applied in the field of reagent plate liquid sampling structure, can solve the problem of liquid splashing at the liquid filling port, and achieve the effect of avoiding liquid splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

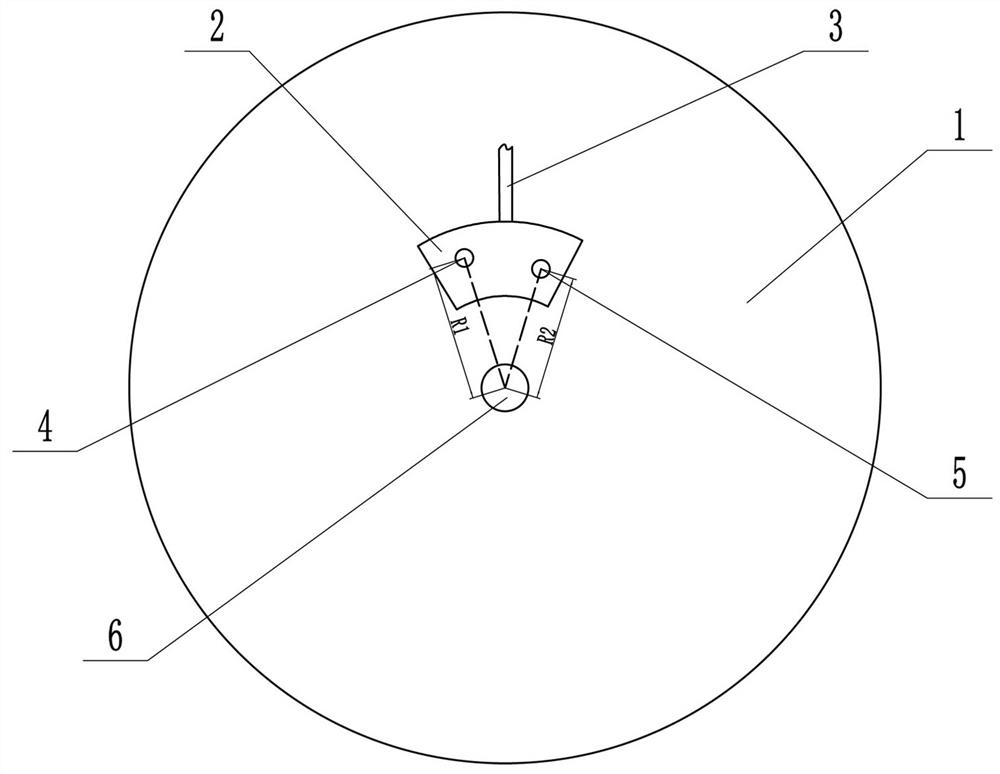

[0008]As attachedfigure 1As shown, the present invention includes a reagent tray 1, a liquid addition tank 2 arranged on the reagent tray 1, and a liquid outlet pipe 3 connected with the liquid addition tank 2. The liquid outlet pipe 3 shown is connected with the subsequent functional area to connect The liquid sample in the liquid addition tank 2 is transported for subsequent processing. The reagent disc 1 has a rotating shaft 6, and the centrifugal force is generated by the rotation of the reagent disc 1 to realize liquid transfer.

[0009]In the present invention, there are two holes on the liquid adding tank 2, namely the exhaust hole 4 and the sample hole 5. The distance between the air exhaust hole 4 and the rotation axis of the reagent disc 1 is R1, and the sample hole The distance between 5 and the axis of rotation of the reagent disc 1 is R2, R2≤R1, so that when the sample is added from the sample hole 5 and the centrifugal operation is performed, the compression hole in the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com