Clutch structure for windlass

A windlass and reel technology, applied in the direction of anchoring/lashing, ship parts, ships, etc., can solve the problems of poor stability, low efficiency, high safety and stability requirements, etc., to enhance stability and improve practicality sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention provides a clutch structure for a windlass, which is suitable for the field of ship windlasses. The present invention can be implemented in the following ways:

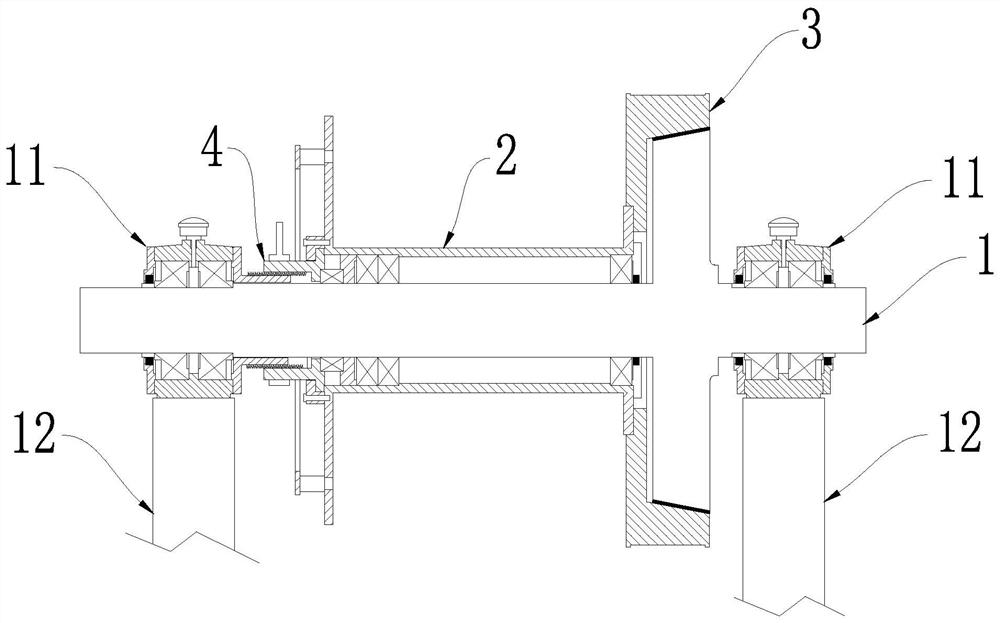

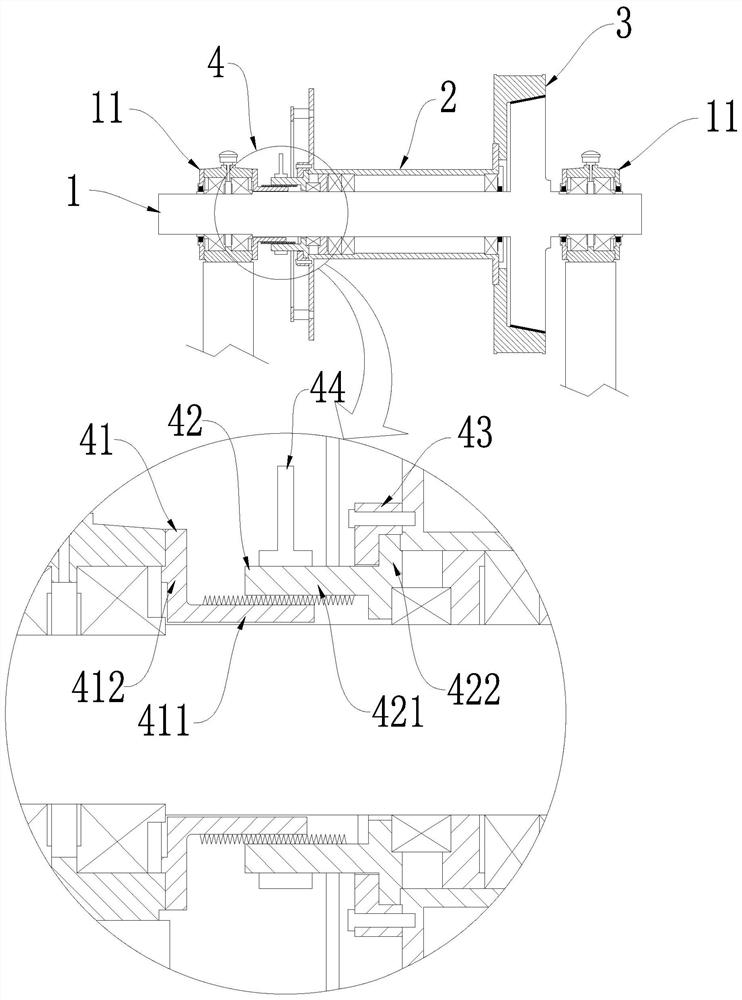

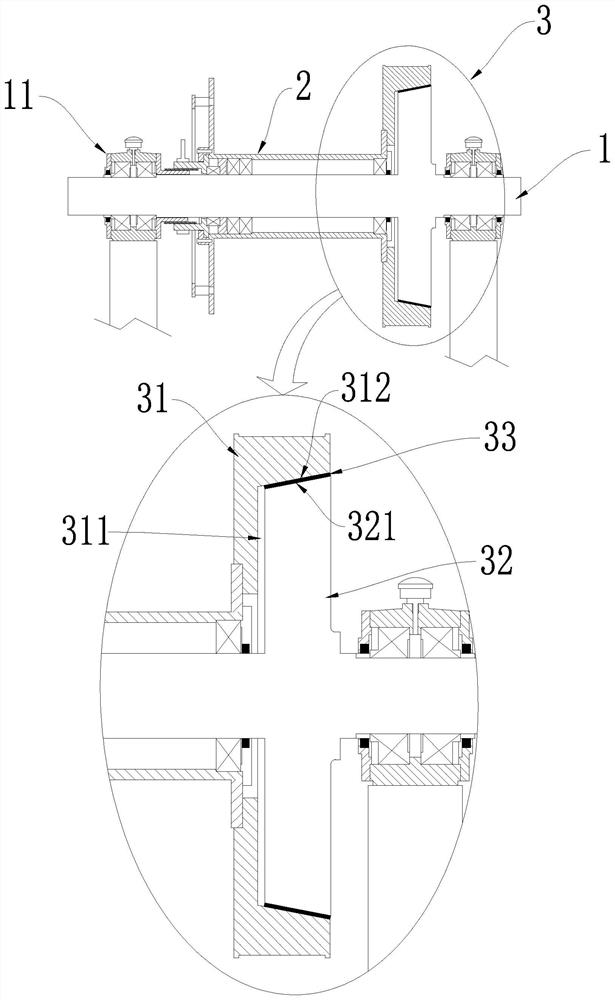

[0034] like Figure 1-17 As shown: the main functional structure of the windlass includes a main shaft 1, a reel 2, and the reel 2 is used to wind cables or chains, etc. The main shaft 1 is connected to the power structure and rotates under the drive of the power structure. Therefore, the main shaft 1 is the power main shaft. The reel 2 is set on the main shaft 1 and rotates under the control of the main shaft 1 to pull the cable; 1 Flexible connection, that is, independent rotation between the reel 2 and the main shaft 1, the reel 2 can slide axially on the main shaft 1, but there is a clutch structure 3 and a clutch between the reel 2 and the main shaft 1 to control the rotation of the reel 2 control structure4.

[0035] like figure 1 , 3 -As shown in 4, 6, 7, 14-17: the clutch structure 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com