Ion adsorption type rare earth ore in-situ leaching field drip washing and sealing method and application

An ion adsorption type, in-situ leaching technology, applied in the direction of improving process efficiency, can solve problems such as ammonia nitrogen pollution, and achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0050] There can be many specific sources of rinse water. As an optional embodiment of the present invention, the rinsing water includes rinsing tail water that has been treated up to standard.

[0051] The leaching tail water that has been treated up to the standard can be understood as the effluent after the in-situ leaching tail water is treated by membrane method, biological method, chemical method and other methods and meets the requirements of national or local discharge standard limits.

[0052] The leaching tail water that has been treated up to the standard is used as the rinsing water to perform one-step rinsing on the in-situ leaching field, which can realize the recycling of the leaching tail water.

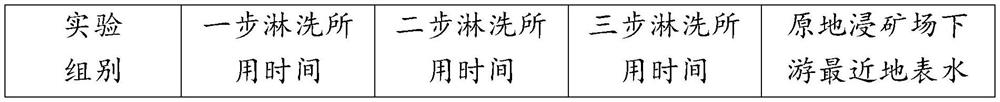

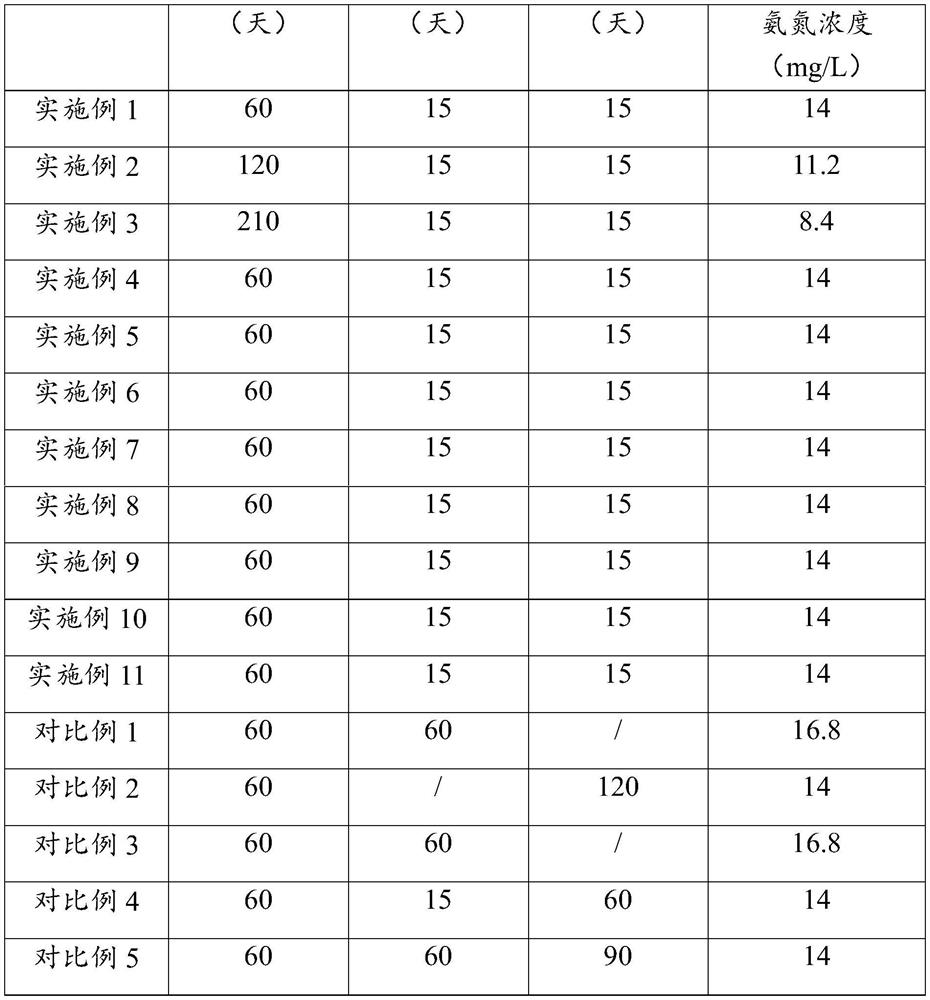

[0053] As an optional embodiment of the present invention, the concentration of ammonia nitrogen in the rinse tail water that has been treated up to the standard is not greater than 15 mg / L. The typical but non-limiting concentration of ammonia nitrogen in the leachi...

Embodiment 1

[0083] This embodiment provides a method for rinsing and closing an ion-adsorption type rare earth ore in-situ leaching field, including the following steps:

[0084] (a) Provide leaching water: Membrane treatment facilities are used to treat the tail water or leaching tail water of the in-situ leaching field. ) as rinse water;

[0085] The infiltration coefficient of the in-situ leaching field is 0.14, and the concentration of ammonia nitrogen in the leaching water (leaching water formed by natural rainfall) before leaching in the in-situ leaching field is about 1200mg / L. The in-situ leaching field is subjected to one-step leaching at the speed of field injection, and the leaching effluent enters the membrane treatment facility for treatment, and the treated effluent is used for repeated leaching, until the concentration of ammonia nitrogen in the one-step leaching water reaches 140 mg / L, and the one-step leaching wash finished;

[0086] (b) The standard tail water obtained...

Embodiment 2

[0094] This embodiment provides a method for rinsing and closing the in-situ leaching field of ion-adsorption rare earth ore, except that the concentration of ammonia nitrogen in the effluent water reaches 120mg / L in step (a), and the one-step leaching ends and step (b) The concentration of ammonia nitrogen in the effluent water of the second-step leaching reaches 100mg / L, the concentration of ammonia nitrogen in the effluent water of the second-step leaching and the three-step leaching in step (c) reaches 80mg / L, and the three-step rinsing ends, and the remaining steps are the same as in Example 1 same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com