Preparation method of maleic anhydride graft polypropylene wax and device thereof

A technology for grafting polypropylene and maleic anhydride, which is applied in the field of production and preparation of maleic anhydride grafted polypropylene wax and its device field, can solve the problems of high cost, unreasonable economy and the like, and achieves reduced adverse effects and improved effectiveness. Grafting rate, the effect of realizing economic development and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

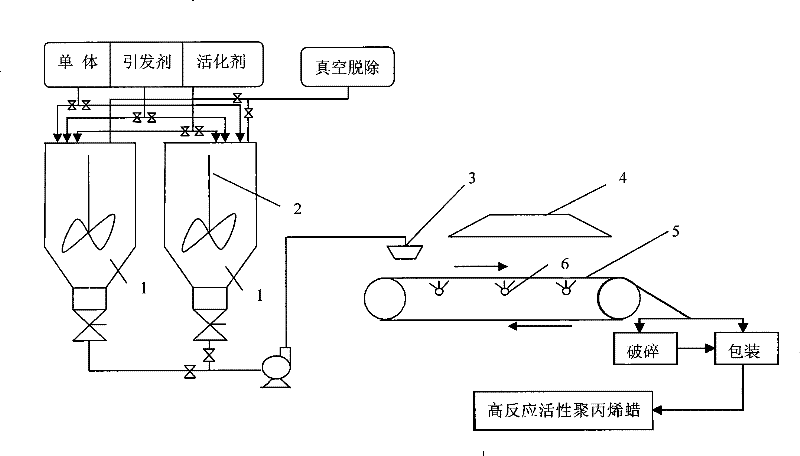

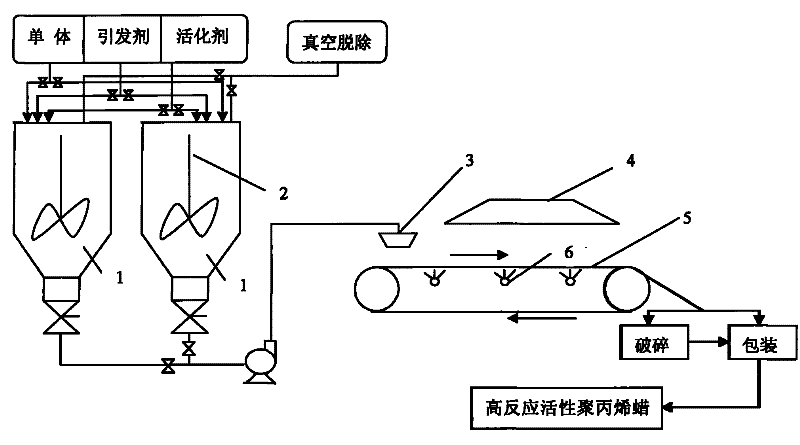

[0029] The structure of the device is as figure 1 As shown, 1-melting reactor; 2-stirrer; 3-die; 4-dust cover; 5-transmission steel belt; 6-cooling water;

[0030] A production and preparation device for maleic anhydride grafted polypropylene wax, the reaction kettle is equipped with a heating system and agitator, the top is connected to the feeding hopper through a connecting pipe, and at the same time, connected to a vacuum removal device through a connecting pipe, and the reaction kettle is connected through a valve Connect the inlet of the conveying pump with the connecting pipe, and connect the outlet of the conveying pump to the die head through the connecting pipe, and the die head is arranged above the conveyor belt of the rotary belt condensing granulator. A dust collection hood is arranged above the conveyor belt, and the cooling to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com