Reaction cup washing mechanism and reaction cup washing method

A technology for cuvettes and cup holes, which is applied in separation methods, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems of easy carryover pollution, low cleaning efficiency of cuvettes, and large loss of tips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

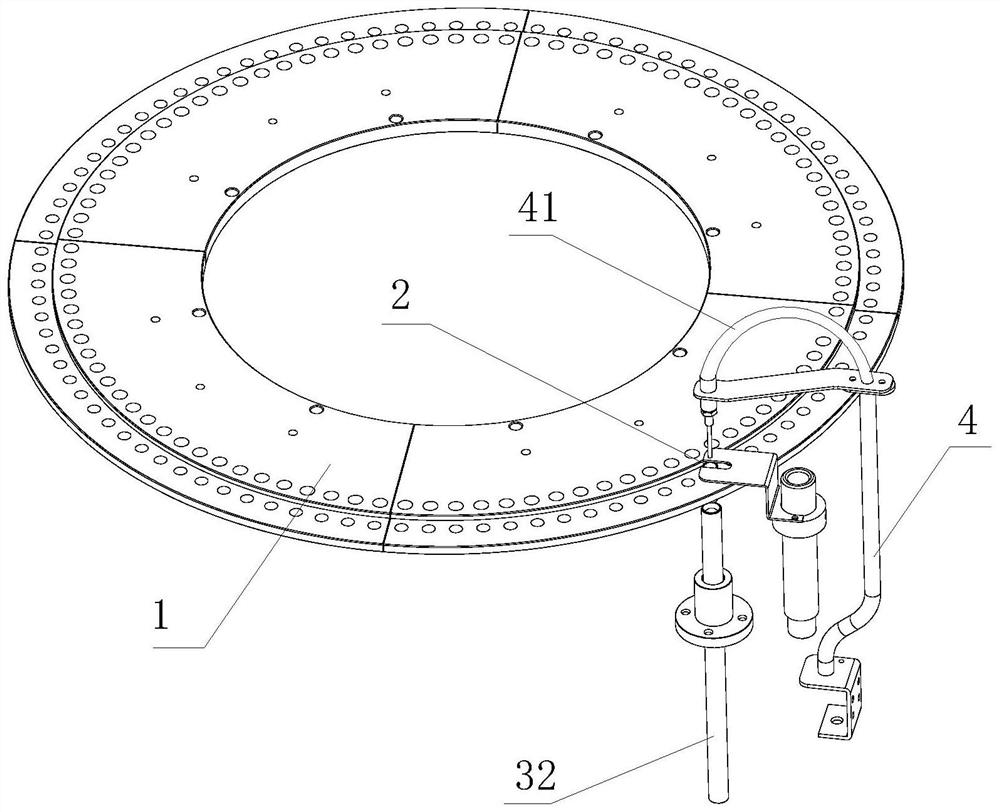

[0044] like Figure 1 to Figure 4 As shown, a cuvette washing mechanism includes an operating table, on which a cup and tray 1 is arranged, and the cup and tray 1 are moved and set on the operating table; a plurality of cup placement holes are provided on the cup and tray 1, The cuvette 2 is placed in the cup hole;

[0045] Reaction cup 2, the upper end of the reaction cup 2 is provided with a liquid inlet, and the bottom is provided with a liquid discharge port. The liquid discharge port is provided with a filter membrane 23. When the liquid discharge port is at normal pressure, the filter membrane 23 is suitable for supporting the reaction Sample reaction solution in cup 2;

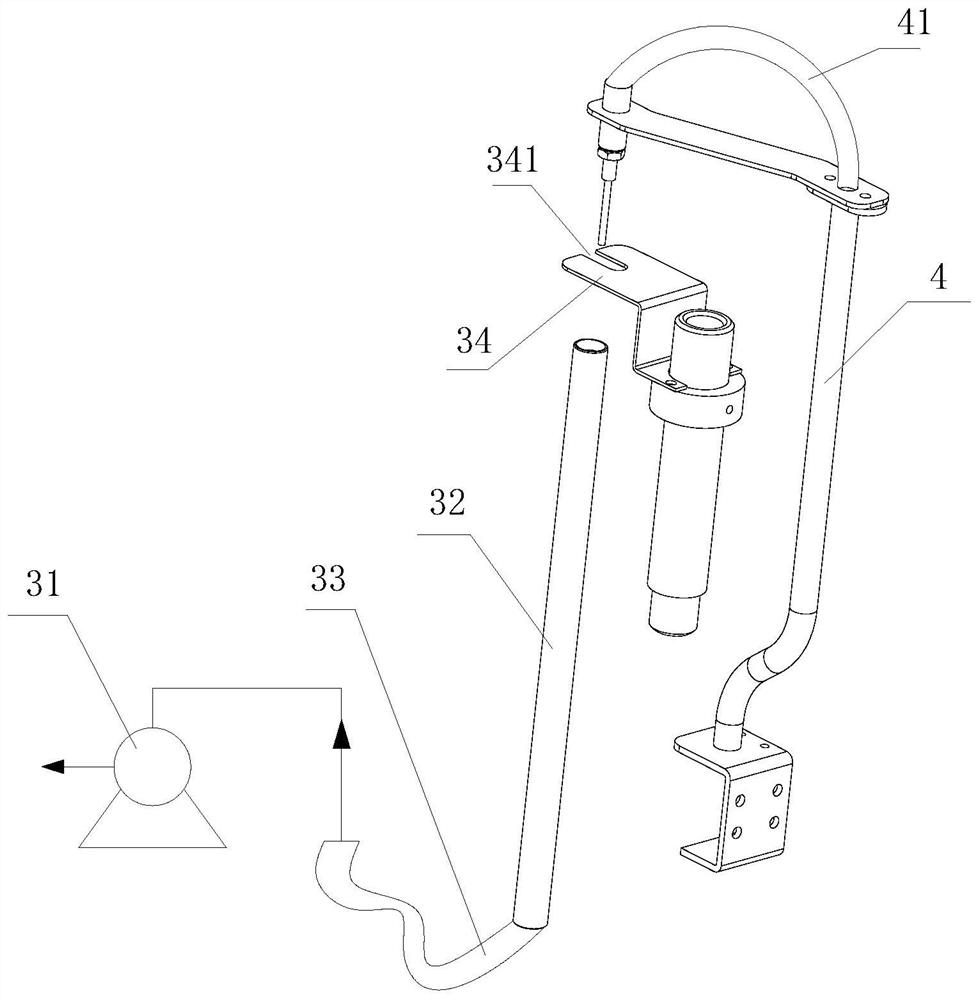

[0046] A liquid discharge mechanism 3, when the cuvette 2 moves to the liquid discharge station of the console, the liquid discharge mechanism 3 is in sealing connection with the liquid discharge port at the bottom of the cuvette 2, and provides negative pressure to the liquid discharge port to Drain ...

Embodiment 2

[0064] A method for washing cuvettes, using the cuvette 2 washing mechanism of Embodiment 1, comprising the following steps:

[0065] Step S01, the cuvette 2 is filled with a mixture of the sample and the microsphere reagent, and the cuvette 2 moves on the operating table along with the cup and tray 1;

[0066] When the cuvette 2 moves to the liquid discharge station, at this time, the cuvette 2 is located below the baffle 34;

[0067] Step S02, the push-pull electromagnet drives the hard tube 32 to move upward until the upper end of the hard tube 32 forms a sealing fit with the liquid discharge port at the bottom of the cuvette 2, and then the negative pressure pump 31 works to remove the mixed liquid in the cuvette 2, The filter membrane 23 keeps the microsphere sieve in the mixed solution in the cuvette 2;

[0068] Step S03, then fill the cuvette 2 with cleaning solution through the liquid filling pipe 41, and clean the microspheres through the cleaning solution. After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com