Pipe blank cutting device

A technology for cutting devices and tube blanks, which is applied in the direction of pipe shearing devices, shearing devices, and auxiliary devices of shearing machines, etc., which can solve the problems of inconvenient cutting length adjustment, small application range, and increased costs, and achieve high work efficiency. , Reasonable structural design, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

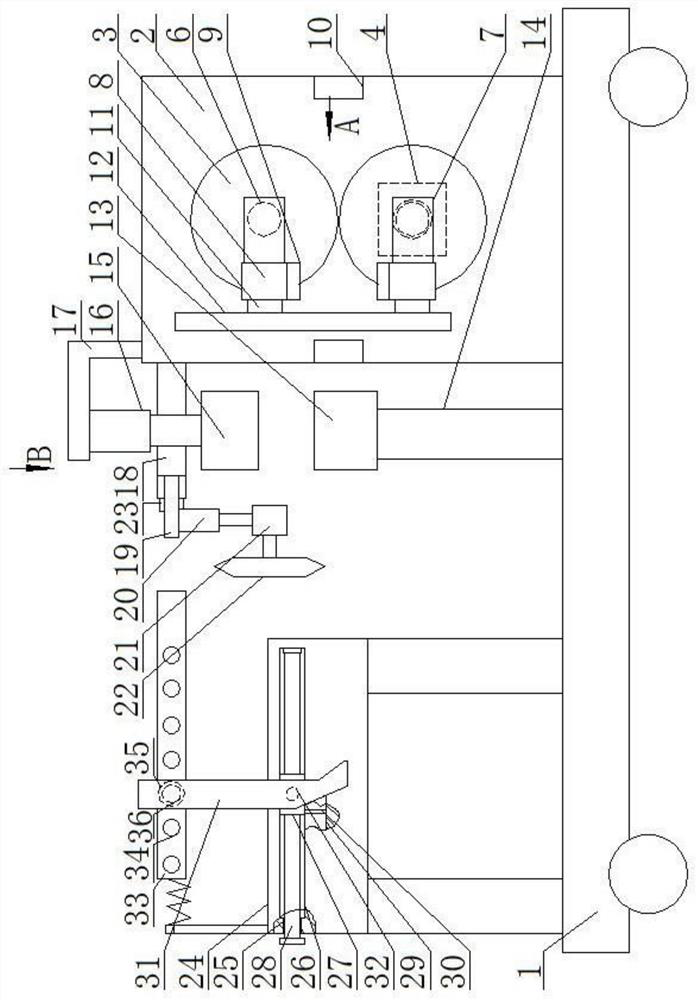

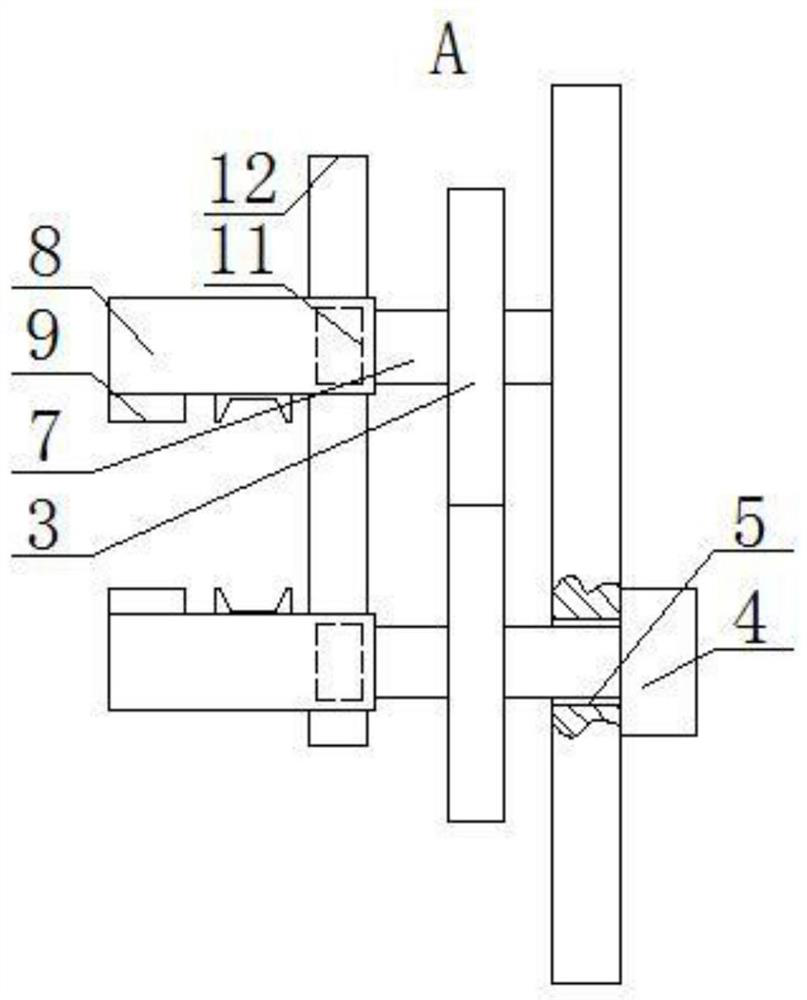

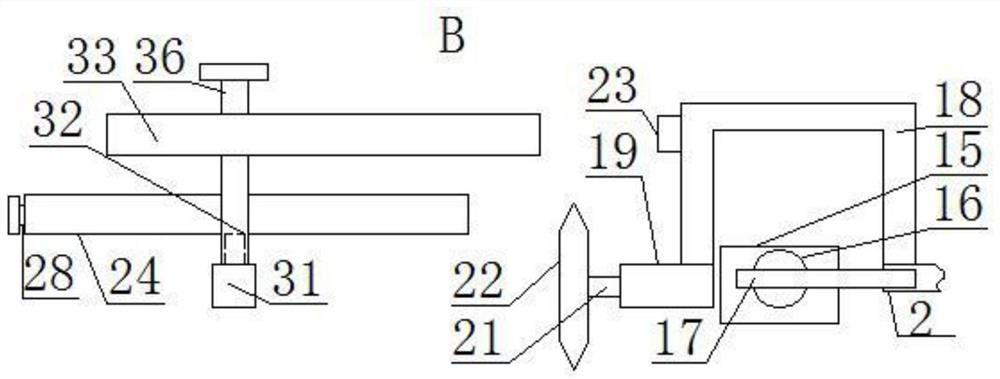

[0012] Such as Figure 1 to Figure 3 As shown, a tube billet cutting device specifically disclosed in this embodiment includes a base 1, a vertical plate 2 is fixedly installed on one side of the top surface of the base 1, and two circular plates 3 placed up and down are arranged in front of the vertical plate 2. The two circular plates 3 can be in contact with each other, the rear surface of the vertical plate 2 is fixedly installed with the first motor 4, the rear surface of the vertical plate 2 is provided with a through hole 5, and the output shaft of the first motor 4 passes through the through hole 5 and passes through the through hole 5. The bearing is fixedly connected, the output shaft of the first motor 4 is fixedly connected with the rear surface of one of the circular plates 3, the front surface of one of the circular plates 3 and the front and rear surfaces of the other circular plate 3 are all fixedly installed with the rotating rod 6, and the other circular plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com