Tea leaf water-removing and straightening integrated machine

A kind of greening and all-in-one machine technology, applied in the direction of tea processing before extraction, can solve the problems of increasing tea processing time, affecting tea processing quality, reducing tea production efficiency, etc., saving labor and time costs, and reducing labor intensity , the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

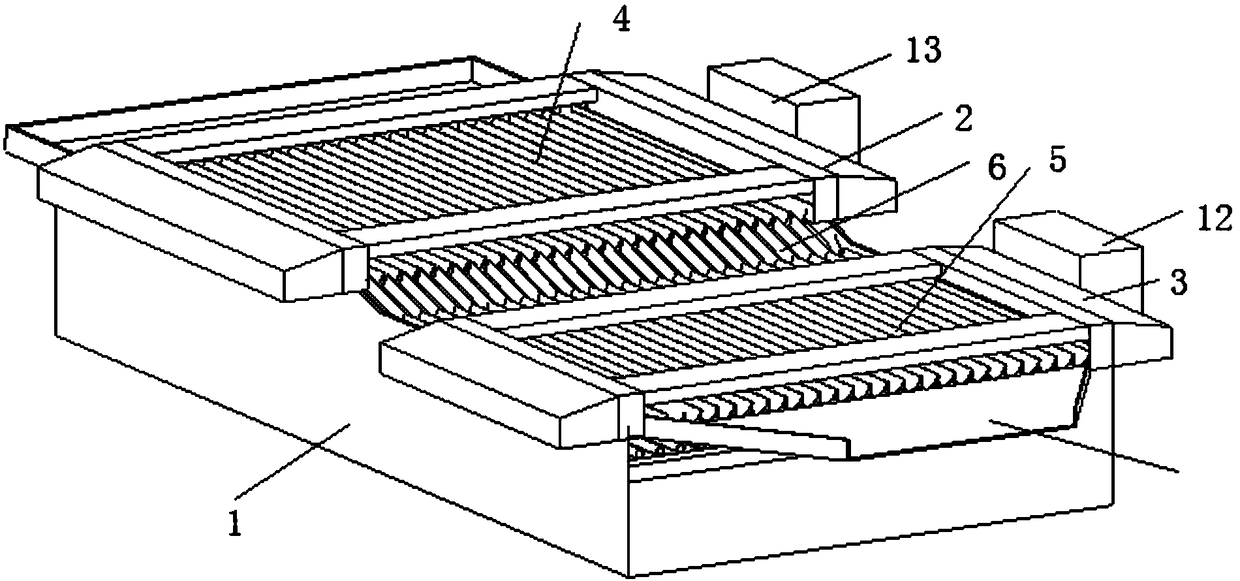

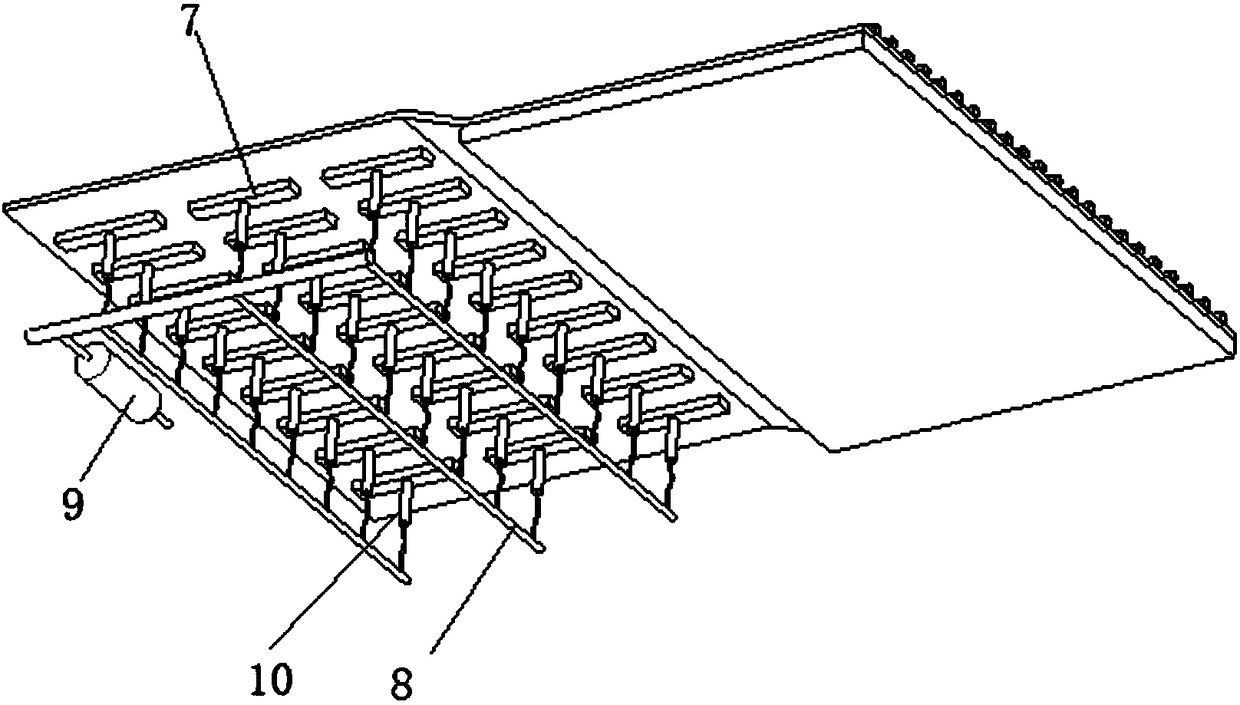

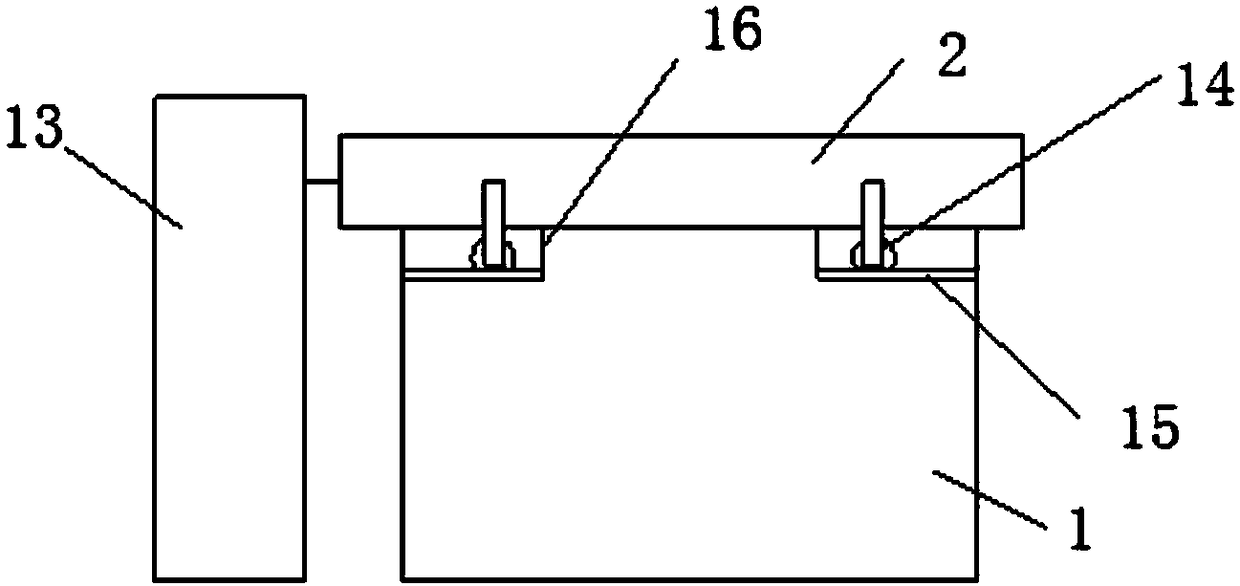

[0019] Examples such as figure 1 , figure 2 , image 3 The illustrated tea finishing and finishing integrated machine includes a frame 1, a heating mechanism is arranged on the frame 1, and a finishing frame 3 and a finishing frame 2 that can swing left and right are arranged above the heating mechanism, and the finishing frame 3 and finishing frame The two frames 2 are independent of each other and the swing frequency is adjustable; the fixing frame 2 is provided with a fixing groove plate 4 inclined downward from its feed end to its discharge end, and the trimming frame 3 is provided with a fixing groove plate 4 from its feed end to its Arrangement slot plate 5 with the discharge end inclined downward; the discharge end of the finishing groove plate 4 matches the feed end of the finishing groove plate 5; the feed end of the finishing groove plate 5 is lower than the finishing groove plate 4 The end of the discharging end is provided with an over-connection slot plate 6 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com