Electric power tool storage scaffold

A technology for power tools and construction racks, which is applied to tool storage devices, manufacturing tools, etc., can solve the problems of inconvenient storage, inconvenience of folding, and inconvenience in carrying, and achieves the effect of reducing the space occupied by the area, facilitating the wiring operation, and being easy to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

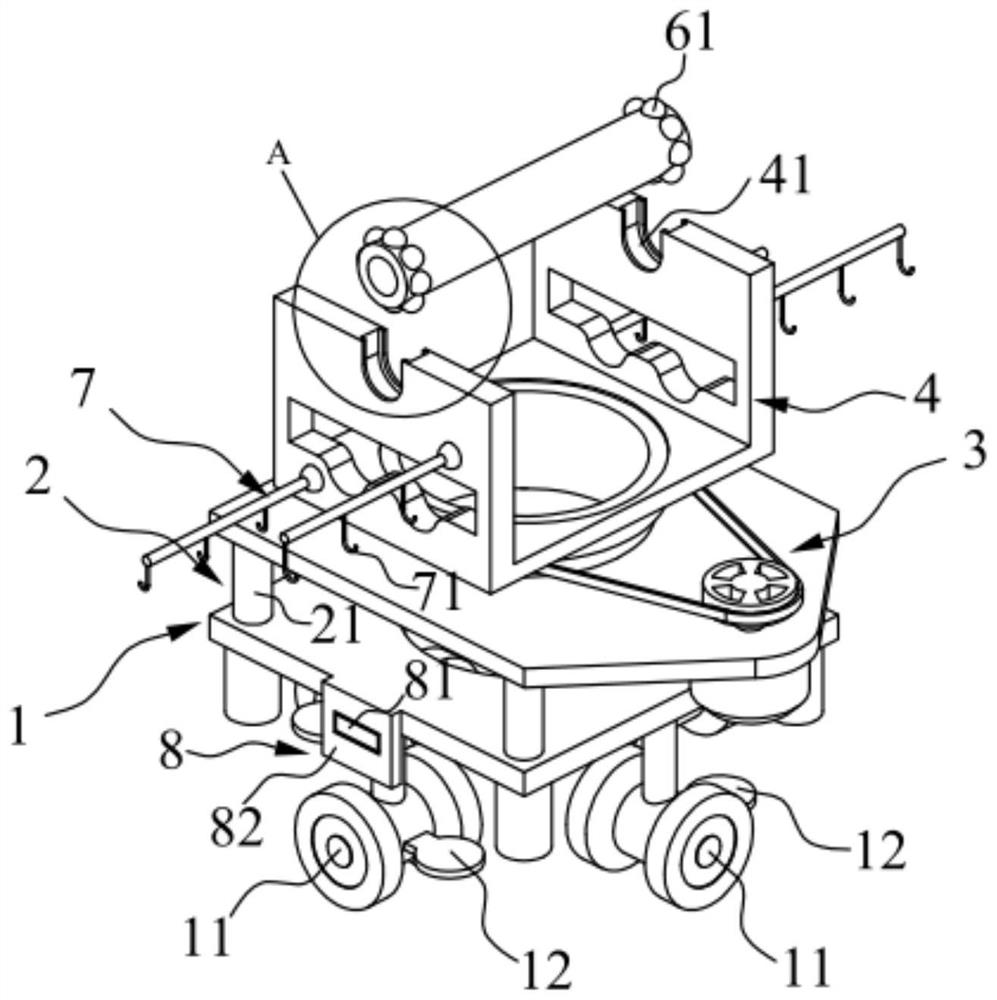

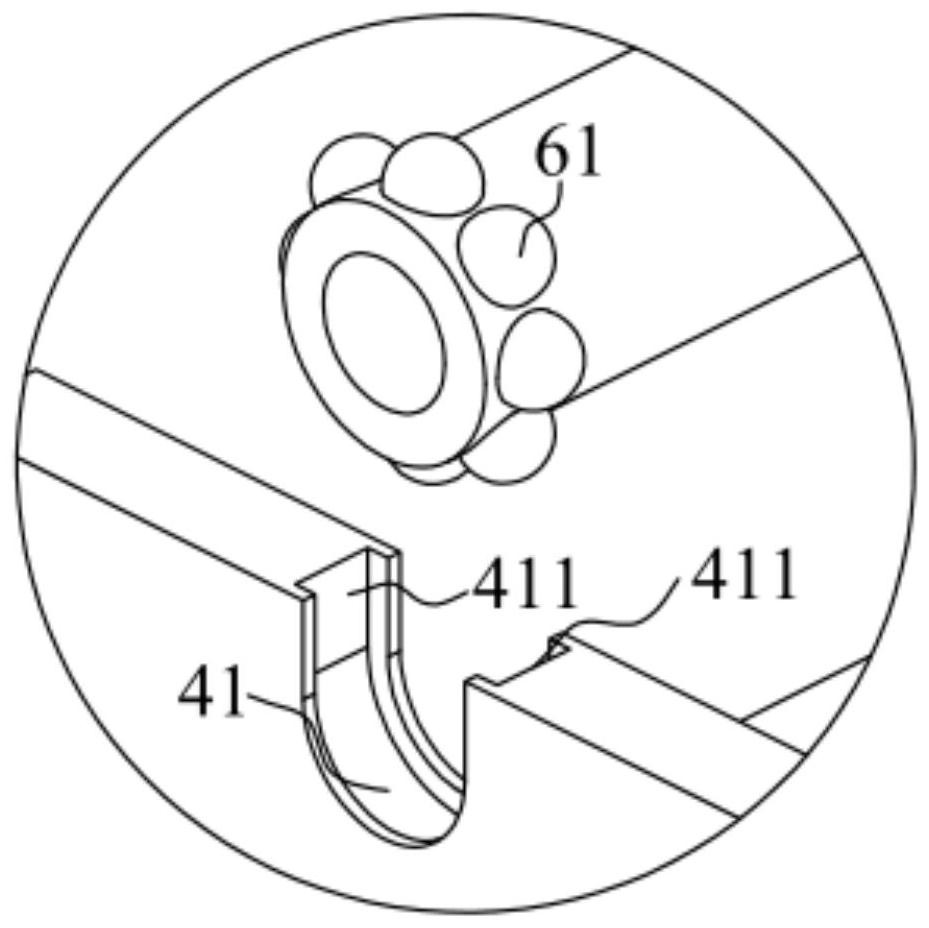

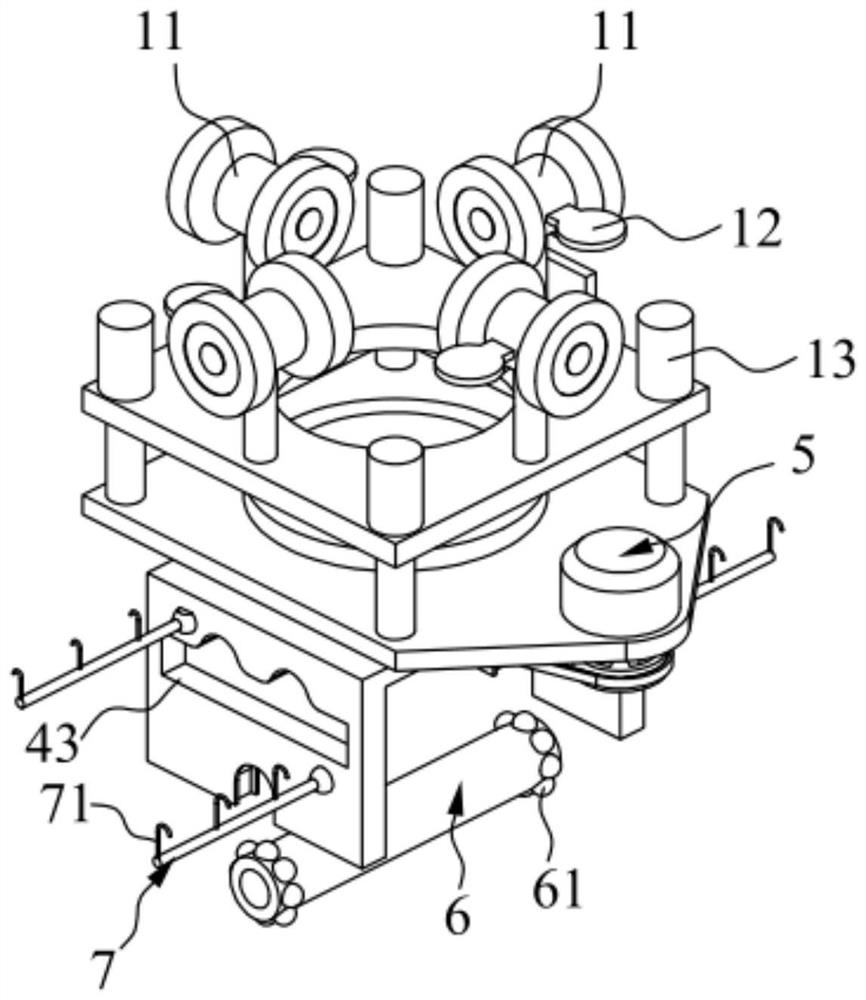

[0041] Such as Figure 1-Figure 4 As shown, the present invention provides a power tool storage construction frame, including a base 1, a lifting mechanism 2, a mounting seat 3, a support frame 4, a driving device 5, a pay-off shaft 6 and a plurality of hanging rods 7, the lifting mechanism 2 One end is fixedly connected with the base 1; the mounting base 3 is fixedly installed on the other end of the lifting mechanism 2, and the lifting mechanism 2 can drive the mounting base 3 to lift in the vertical direction; the support frame 4 is rotatably installed on the mounting base 3, and the support frame 4 is set There are two supporting grooves 41; the driving device 5 is fixedly installed on the mounting base 3, and the driving device 5 is configured to drive the supporting frame 4 to rotate; Rotation connection (in the accompanying drawings, the structure of the pay-off shaft 6 is shown, so that the pay-off shaft 6 is separated from the support groove 41); In this embodiment, ...

Embodiment 2

[0050] This embodiment is further improved on the basis of embodiment one, as figure 1 As shown, it also includes an integrated control module 8, the integrated control module 8 includes a single-chip microcomputer 81, the single-chip microcomputer 81 is installed on the side of the base 1, and the single-chip microcomputer 81 is connected with the lifting mechanism 2 and the driving device 5 respectively, and can control the lifting mechanism 2 lifting operations , Control and start the driving device 5 to drive the support frame 4 to rotate. In addition, the integrated control module 8 also includes a wireless transceiver 82, which is used for remote interaction of information, and the single-chip microcomputer 81 communicates with the lifting mechanism 2 and the driving device 5 through the wireless transceiver 82 to ensure smooth operation. Convenience and intelligence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com