Active regeneration type diesel particulate filter based on pressure regulation and control

A particle trap, active regeneration technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as affecting the service life of exhaust emission components, sudden rise in pressure difference between front and rear ends, and prevent poor trapping effect. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

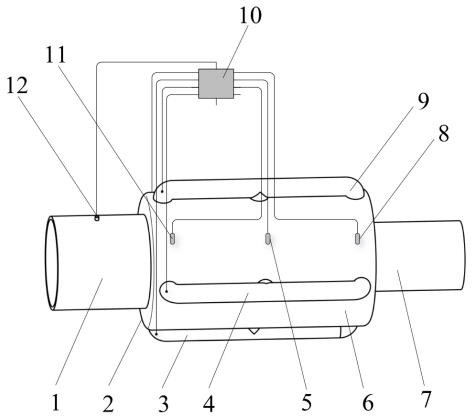

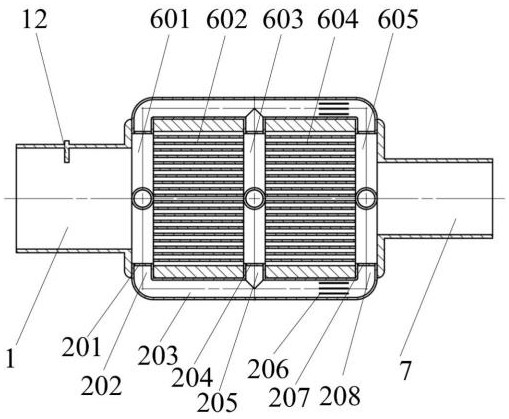

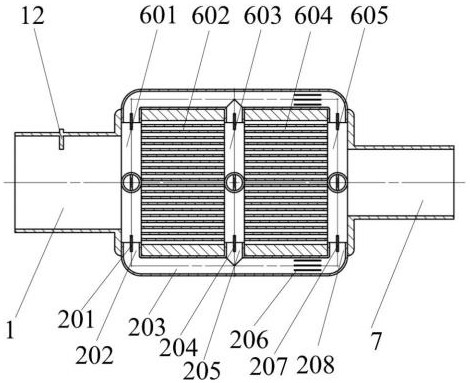

[0018] see figure 1 , the present invention provides an active regenerative diesel particulate filter based on pressure regulation, including a combustion chamber 1, a DPF main body 6, an ECU control unit 10 and a spark plug 12, and an exhaust pipe 7 arranged at the rear end of the DPF main body 6 , the front pressure sensor 11, the middle pressure sensor 5, and the rear pressure sensor 8 arranged inside the DPF main body 6; the first pressure regulating pipeline 2, the second pressure regulating pipeline 3, and the Three pressure regulating pipelines 4, the fourth pressure regulating pipeline 9; the ECU control unit 10 is respectively connected with the first pressure regulating pipeline 2, the second pressure regulating pipeline 3, the third pressure regulating pipeline 4, the fourth pressure regulating pipeline 9, the front end The pressure sensor 11, the intermediate pressure sensor 5, the rear end pressure sensor 8 and the spark plug 12 are connected.

[0019] In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com