Local defect aging diagnosis and evaluation method for power cable

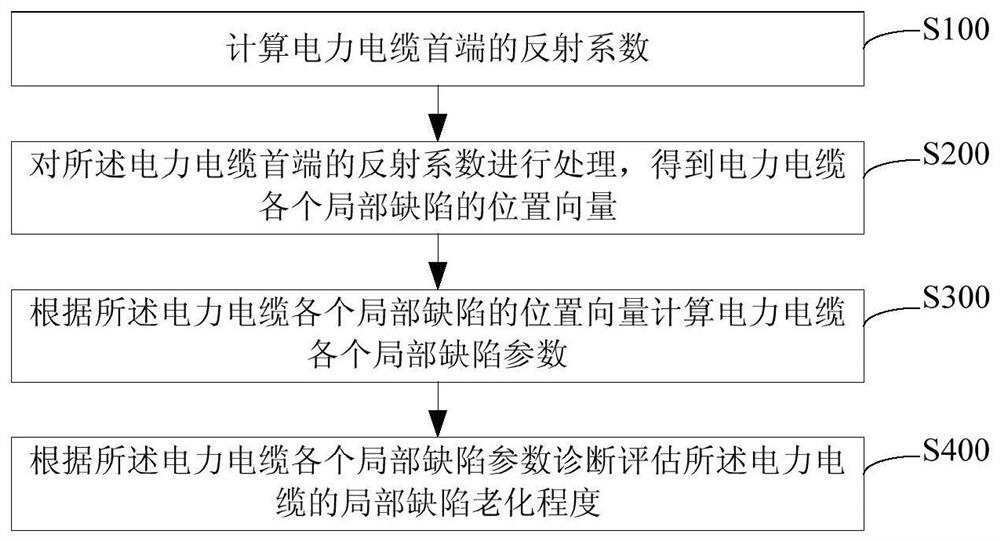

A technology for local defects and power cables, applied in the direction of measuring resistance/reactance/impedance, measuring electrical variables, instruments, etc., to reduce the amount of calculation, reduce the difficulty of calculation, and improve the probability of successful calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] The power cable to be tested in this embodiment is a 1000m ZR-YJV02 8.7 / 15 3*95mm2 power cable, and a resistor with an impedance of 1kΩ is connected in parallel at a position of 300m.

[0108] In this embodiment, an Agilent E5061B vector network analyzer is used to test the input impedance of the head end of the cable under test.

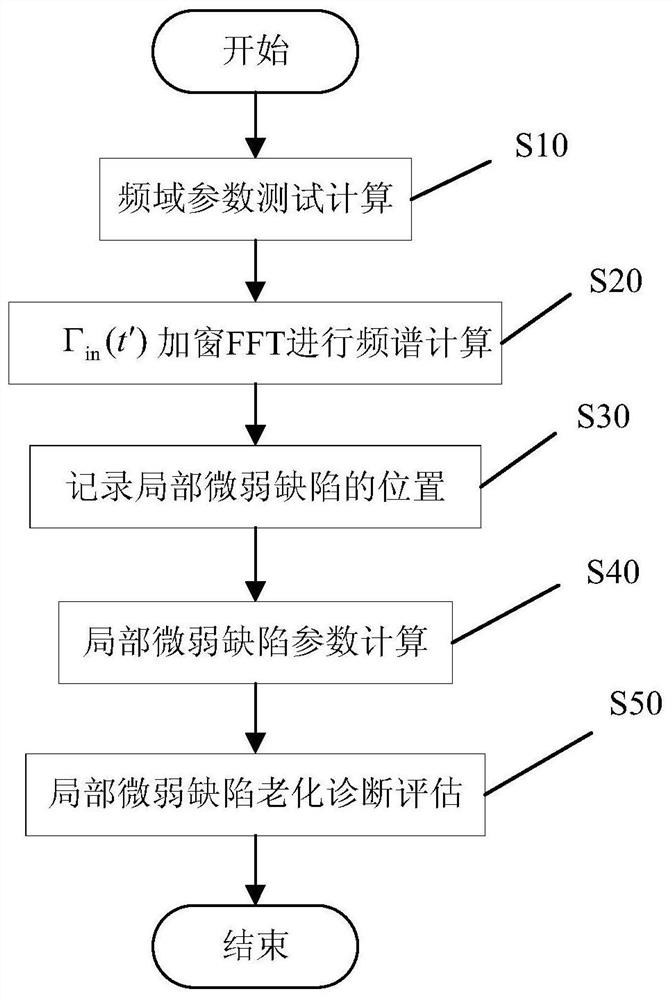

[0109] The local defect aging diagnosis method for power cables provided by this embodiment, such as figure 2 shown, including the following steps:

[0110] S10, frequency domain parameter test calculation

[0111] Set the sweep frequency range of the vector network analyzer to [10kHz, 5MHz], set the number of sweep points N to 1001 and set the input impedance Z at the head end of the power cable in (f) Conduct the test and then calculate the reflection coefficient Γ at the head end of the cable in (f):

[0112]

[0113] Calculated cable head end reflection coefficient Γ in (f) if image 3 shown. Where f is the scanning frequency p...

Embodiment 2

[0127] The power cable to be tested in this embodiment is a 1000m ZR-YJV02 8.7 / 153*95 mm2 power cable, and there is a local weak defect with a length of 1m at a position of 400m.

[0128] In this embodiment, an Agilent E5061B vector network analyzer is used to test the input impedance of the head end of the cable under test.

[0129] The local defect aging diagnosis method for power cables provided by this embodiment, such as figure 2 shown, including the following steps:

[0130] S10, frequency domain parameter test calculation

[0131] Set the sweep frequency range of the vector network analyzer to [10kHz, 5MHz], set the number of sweep points N to 1001 and set the input impedance Z of the cable head end in (f) Conduct the test and then calculate the reflection coefficient Γ at the head end of the cable in (f):

[0132]

[0133] Where f is the scanning frequency point; Z 0 It is the characteristic impedance measured by using a 10m long reference cable of the same mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com