Dispensing method, system and device based on visual guidance and storage medium

A visual guidance and dispensing technology, applied in image analysis, instrumentation, calculation, etc., can solve problems affecting the dispensing and sealing performance of product workpieces, errors in motion systems and vision systems, and affecting the accuracy of dispensing effects, so as to improve production quality. And the effect of production efficiency, high dispensing precision and stable dispensing trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] In view of the defects in the prior art, the inventor actively researches and innovates on the basis of years of rich practical experience and professional knowledge in this industry, and cooperates with the application of academic theory, in order to create a feasible dispensing technology based on visual guidance , making it more practical. After continuous research, design and repeated trials and improvements, the present invention with real practical value is finally created.

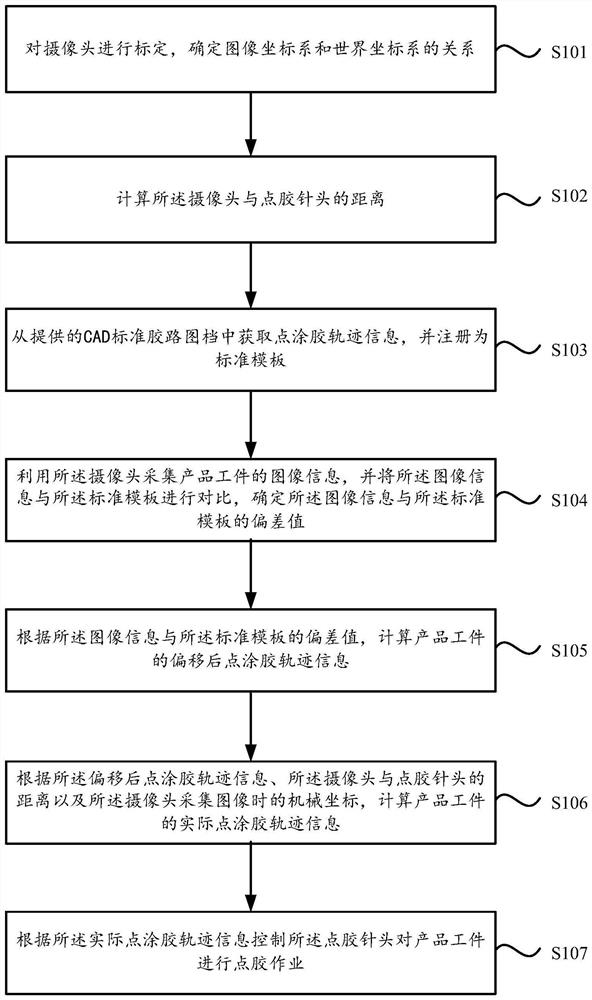

[0059] see figure 1 , figure 1 It is a schematic flow chart of a vision-guided dispensing method disclosed in an embodiment of the present invention. The method is suitable for dispensing glue on product workpieces. The method is performed by a vision-guided dispensing system, which can Implemented by software and / or hardware. Such as figure 1 Shown, this dispensing method based on visual guidance can comprise the following steps:

[0060] S101. Calibrate the camera, and determine the re...

Embodiment 2

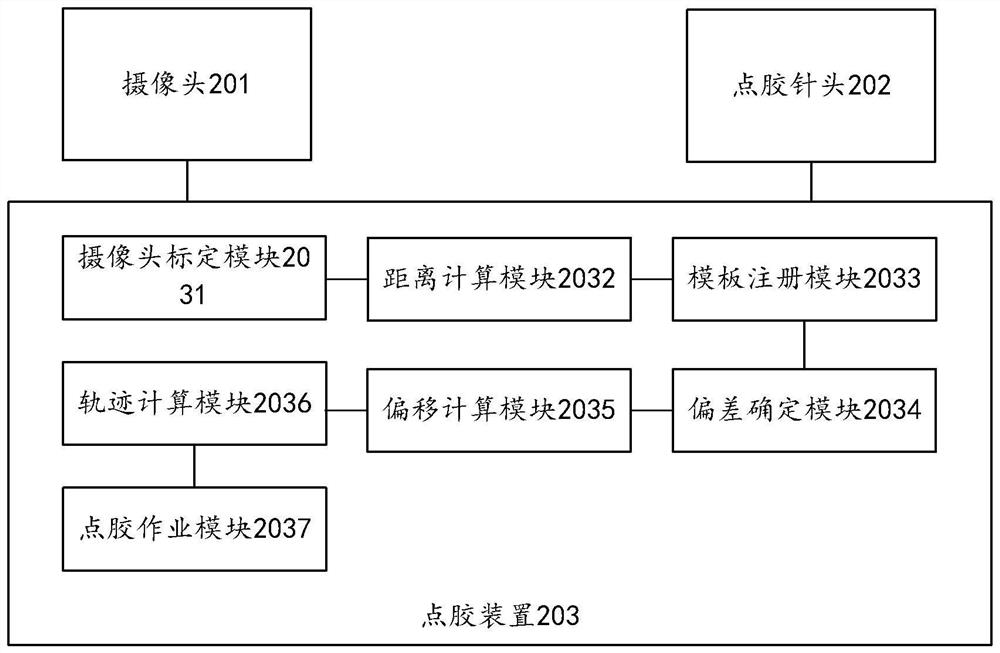

[0083] Please refer to the attached figure 2 , is a functional module schematic diagram of a vision-guided dispensing system provided in Embodiment 5 of the present invention, and the system is suitable for implementing the vision-guided dispensing method provided in the embodiment of the present invention. The system specifically includes the following modules:

[0084] Camera 201, for collecting images;

[0085] The dispensing needle 202 is used for dispensing the product workpiece;

[0086] Glue dispensing device 203, comprising:

[0087] The camera calibration module 2031 is used to calibrate the camera to determine the relationship between the image coordinate system and the world coordinate system;

[0088] A distance calculation module 2032, configured to calculate the distance between the camera and the dispensing needle;

[0089] Template registration module 2033, used to obtain dispensing glue track information from the CAD standard glue road drawing file provid...

Embodiment 3

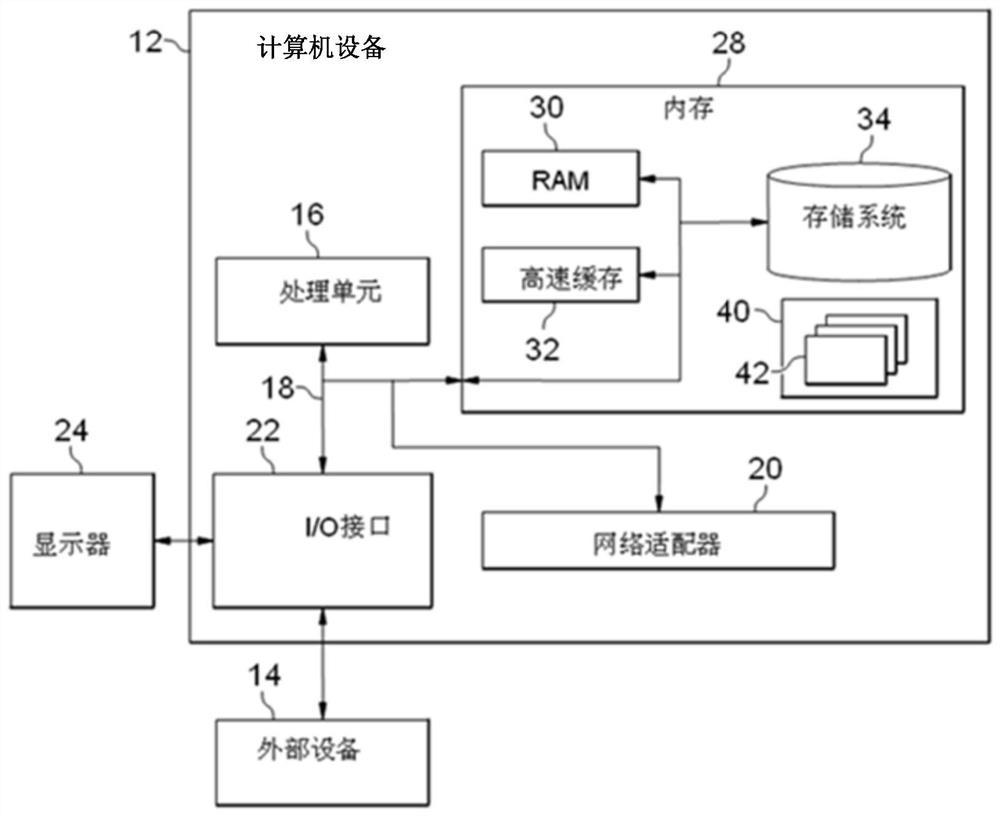

[0104] image 3 It is a schematic structural diagram of a computer device provided by Embodiment 3 of the present invention. image 3 A block diagram of an exemplary computer device 12 suitable for implementing embodiments of the invention is shown. image 3 The computer device 12 shown is only an example, and should not impose any limitation on the functions and scope of use of the embodiments of the present invention.

[0105] Such as image 3 As shown, computer device 12 takes the form of a general-purpose computing device. Components of computer device 12 may include, but are not limited to: one or more processors or processing units 16 , system memory 28 , bus 18 connecting various system components including system memory 28 and processing unit 16 .

[0106] Bus 18 represents one or more of several types of bus structures, including a memory bus or memory controller, a peripheral bus, an accelerated graphics port, a processor, or a local bus using any of a variety of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap