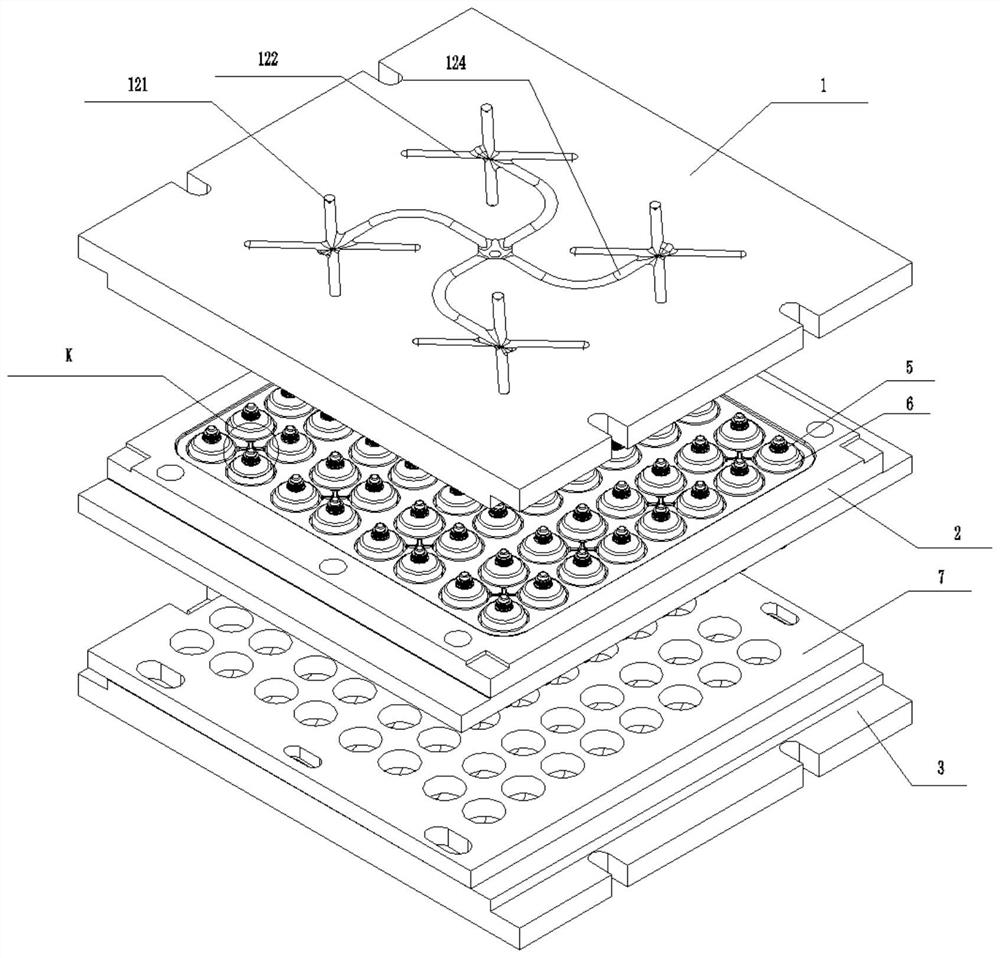

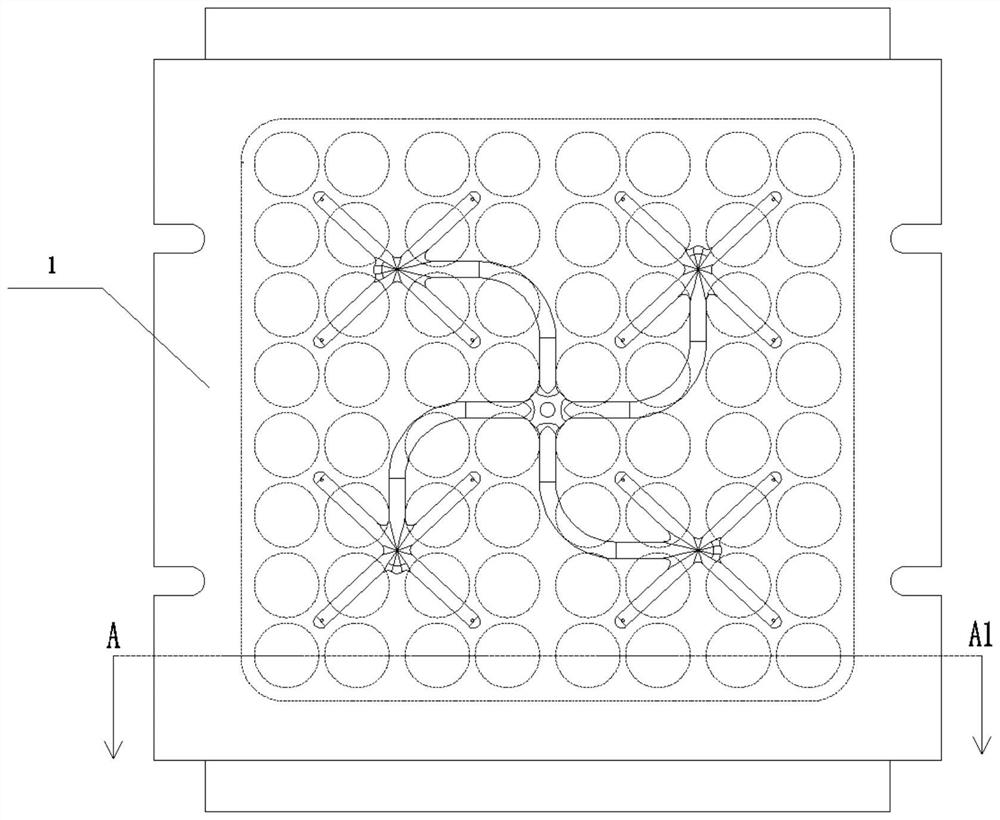

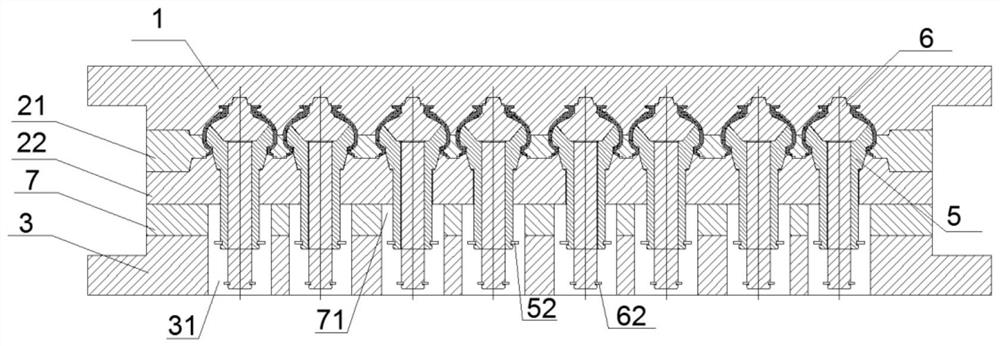

Vulcanizing mold for double-ejection type demolding of automobile ball head dust cover

A technology of vulcanizing mold and dust cover, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of low demoulding efficiency, high resistance, hot redness, etc., and achieve the effect of ingenious design and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in detail below, examples of which are shown in the accompanying drawings, and the embodiments described below by referring to the accompanying drawings are exemplary and are intended to explain the present invention so that the technical solutions of the present invention It is easier to understand and grasp, but cannot be construed as a limitation to the present invention.

[0024] What is explained here is that the mold of the present invention needs to be used in conjunction with a vulcanizing machine. When in use, an air cylinder or an oil cylinder in the prior art is needed to drive the upper mold 1, the middle mold 2, and the moving plate 7 to move, and the lower mold 3 is fixed on the vulcanizing machine. , during the moving process, the guide for moving up and down by the column type in the prior art, the guide for moving left and right by the guide rail type, and the exhaust pipeline is also arranged in the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com