Unwinding device for recovered non-woven fabric

An unwinding device, non-woven technology, which is used in the processing of textile material equipment configuration, spray/jet textile material processing, textile and paper making, etc. problem, to achieve the effect of efficient and environmentally friendly cleaning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

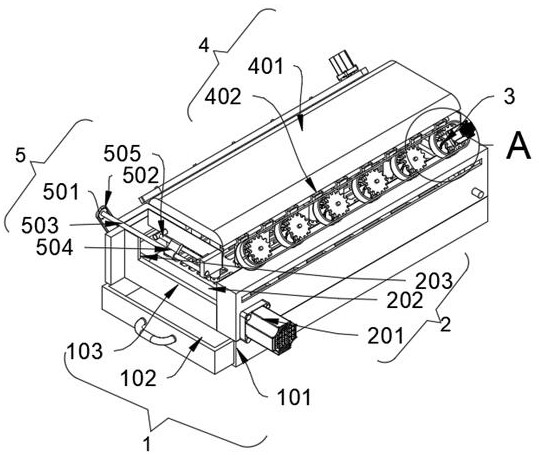

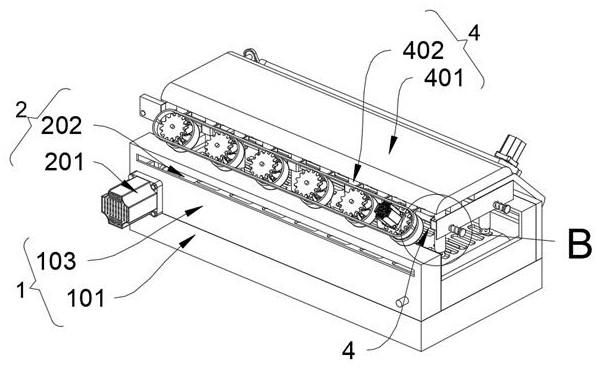

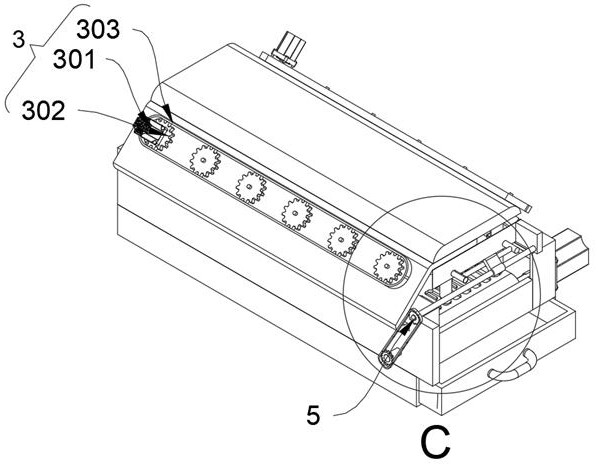

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032] The invention provides a non-woven fabric return uncoiling device, comprising: a feeding mechanism 2, a dust removal mechanism 3 and a flushing mechanism 4, the feeding mechanism 2 is installed in the inner position of the bearing mechanism 1; the dust removal mechanism 3 is equipped with Two places, and the two dust removal mechanisms 3 are respectively installed on the left and right sides of the carrying mechanism 1; the flushing mechanism 4 is installed directly above the carrying mechanism 1 through the guiding mechanism 5; the guiding mechanism 5 also includes a shifting block 504 and The push rod 505 and the shift block 504 are socketed in the middle of the outer peripheral surface of the guide rod 503. There are two push rods 505, and the left ends of the two push rods 505 are arranged in a linear array. The square frame that the left end of 505 is installed is socketed in the outside position of airbag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com