Oblique launching method for large-section rectangular jacking pipe

A technology of rectangular pipe jacking and large cross-section, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc. It can solve the problems of unresolved vertical inclination and pipe joint backfilling, etc., so as to avoid uneven force and prevent deviation from exceeding The effect of limiting and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

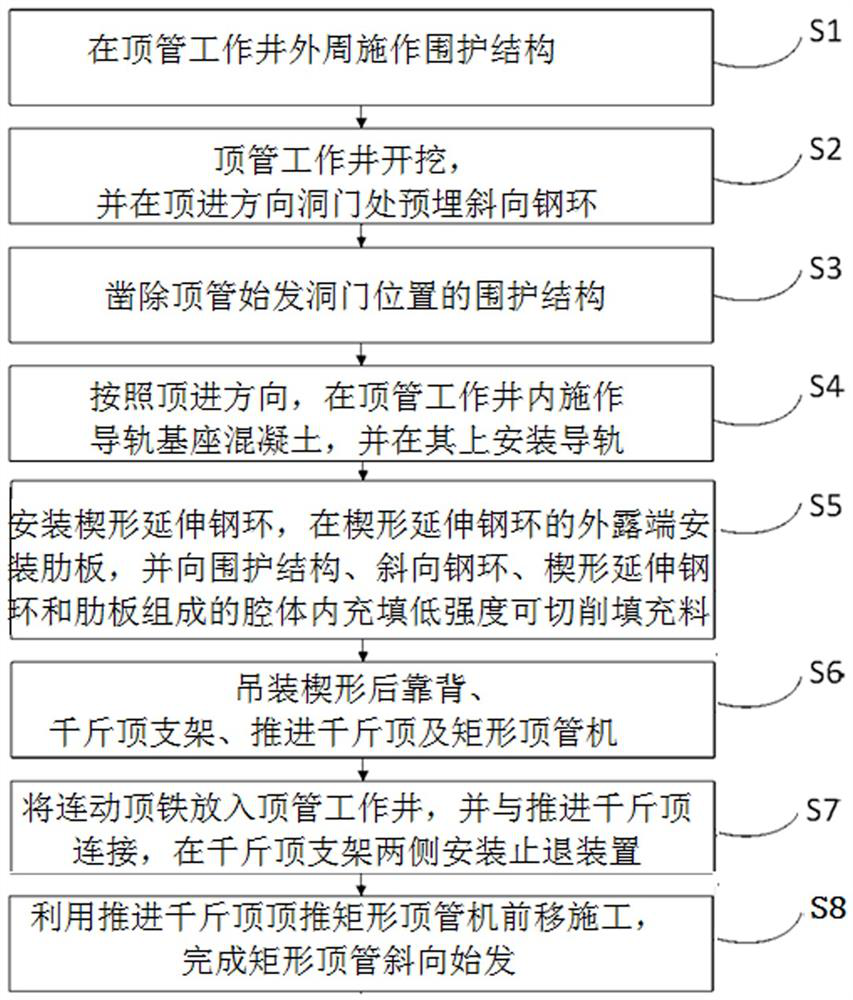

[0040] like Figure 1-11 As shown, a preferred embodiment of the present invention provides a method for oblique initiation of large-section rectangular pipe jacking, including the following steps:

[0041]Step S1. Construct the enclosure structure 1 around the pipe jacking well. Specifically, glass fiber reinforcement is used for the reinforcement of the enclosure structure 1 facing the soil within the scope of the pipe jacking well opening, and the cutter head of the pipe jacking machine can be directly cut. The back soil surface of enclosure structure 1 (pipe jacking well side) adopts steel bars.

[0042] Step S2. Excavating the pipe jacking well, and pre-burying the oblique steel ring 2 at the portal in the jacking direction.

[0043] Step S3. Cut away the enclosure structure 1 at the opening where the pipe jacking starts, remove the reinforced concrete on the back soil surface, and keep the glass fiber reinforced concrete on the soil facing surface (thickness is about o...

Embodiment 2

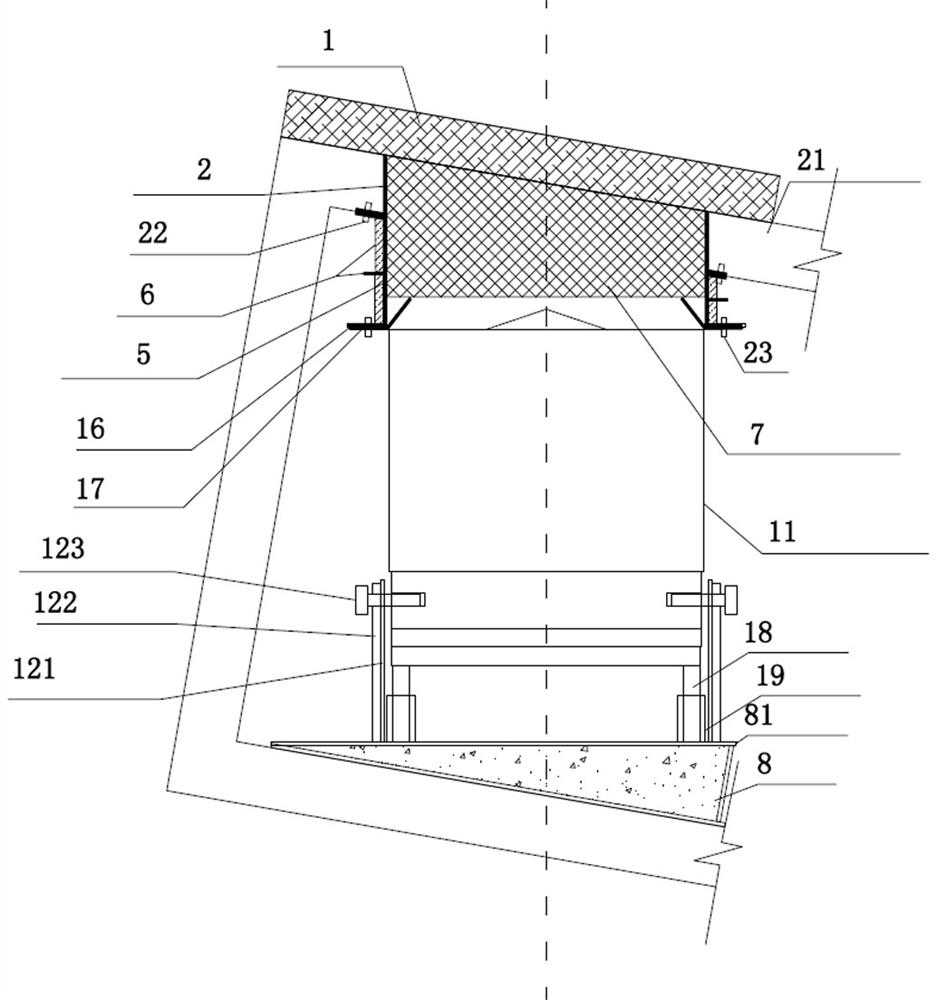

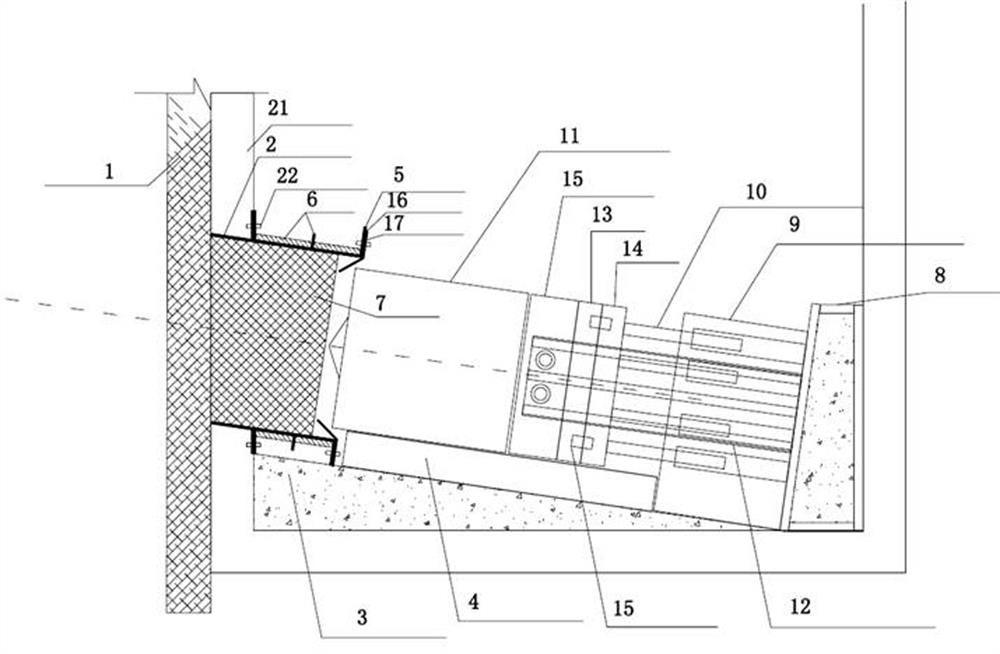

[0057] In another preferred embodiment, the present invention provides a rectangular starting extension structure for pipe jacking, including an enclosure structure 1, an oblique steel ring 2, a guide rail 4, a wedge-shaped extending steel ring 5, and a low-strength machinable filling Material 7, wedge-shaped backrest 8, backstop device 12 and linkage top iron.

[0058] Concretely, the enclosure structure 1 is set outside the side wall 21 of the pipe jacking work well, and the reinforcement on the soil-facing surface of the enclosure structure within the scope of the opening of the work well is made of glass fiber reinforcement, and the cutter head of the pipe jacking machine can be directly cut.

[0059] Specifically, the cross-section of the oblique steel ring is L-shaped, and the overall shape is obliquely rectangular. The oblique direction is the same as the axial direction of the pipe jacking machine. The diameter ratio of the inner ring is greater than the diameter of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap