Sheet material defective product and sample separation and collection device and rejection device

A technology of collection device and rejecting device, which is applied in the field of separation and collection device and rejecting device for defective products and samples of sheet materials, and can solve problems such as inability to distinguish sheet materials and no separation and collection device for defective products and samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

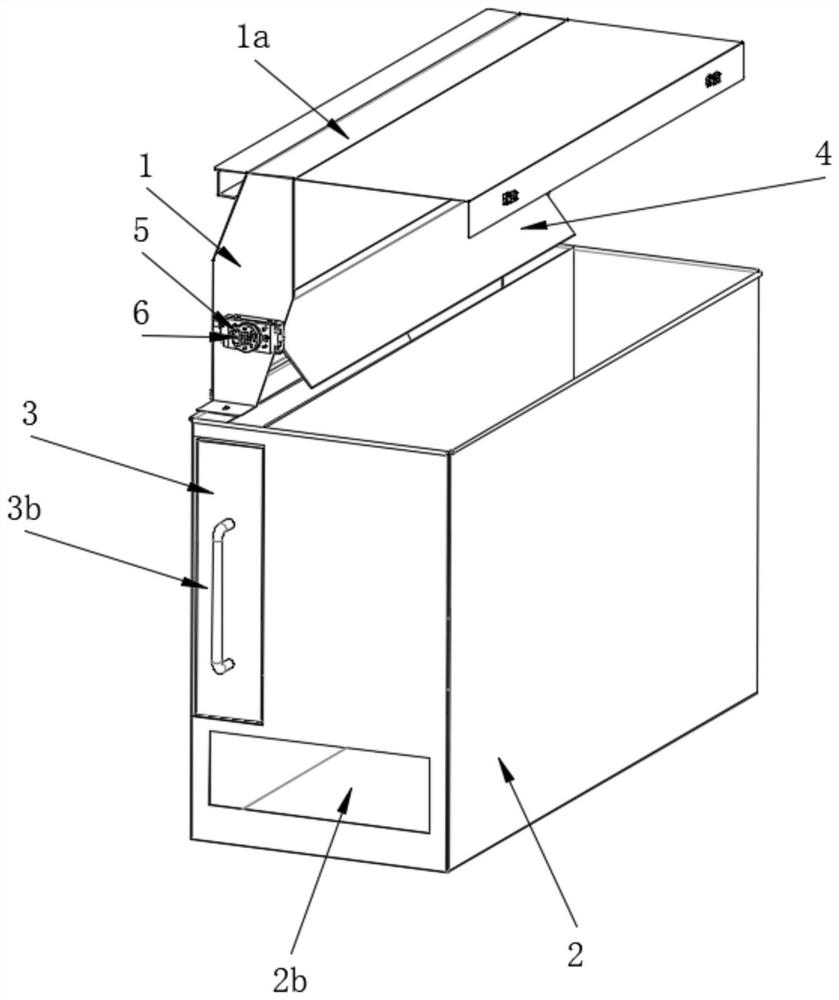

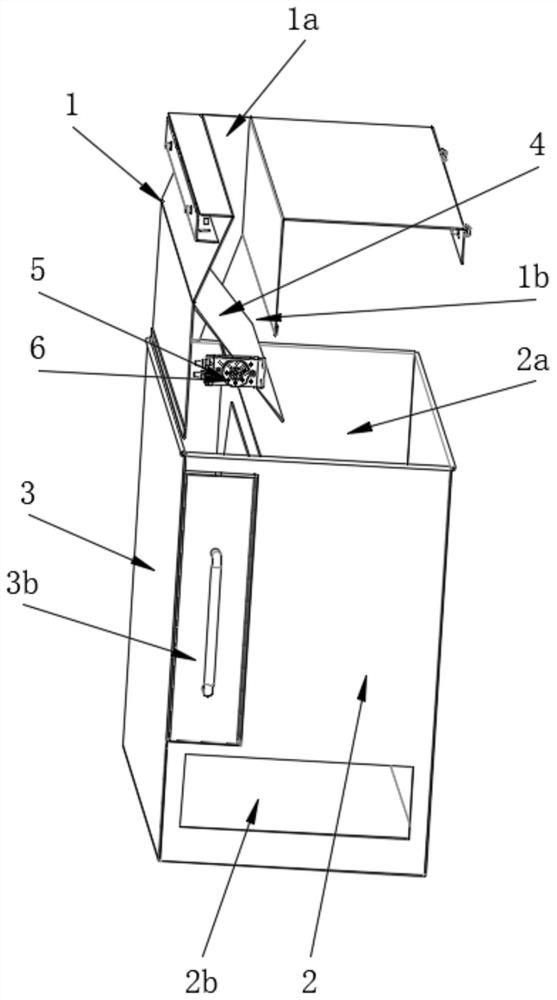

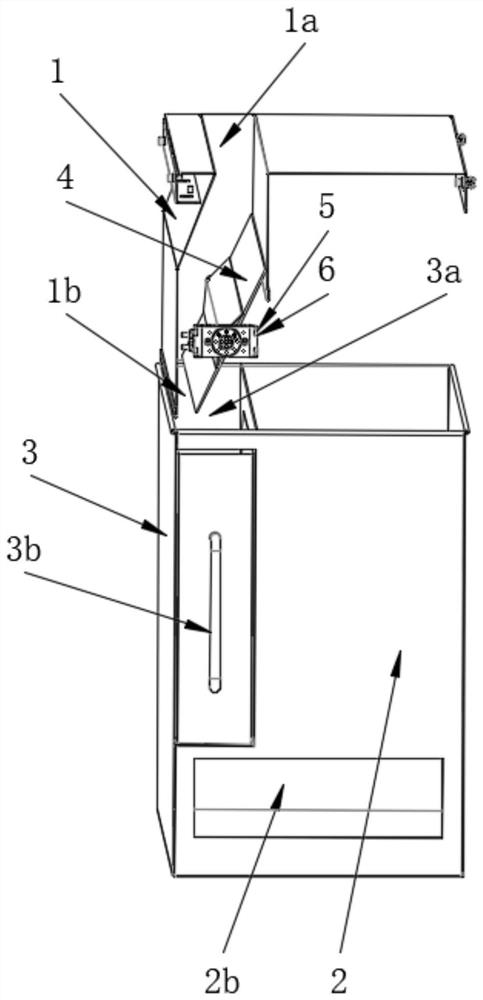

[0033] The sheet material defective product of embodiment 1 and sample separation collection device such as Figure 1 to Figure 3 As shown, the separation and collection device includes a separation box 1, a defective product storage box 2, a sample storage box 3, a partition 4 and a partition switching device 5; the separation box 1 is located between the defective product storage box 2 and the sample storage box 3 Above, the upper part of the separation box 1 is provided with a sheet material inlet 1a, the lower part of the separation box 1 is provided with a sheet material outlet 1b, the upper part of the defective product storage box 2 is provided with a defective product inlet 2a, and the sample storage box 3. The upper part is provided with a sample inlet 3a; the partition 4 is arranged in the separation box 1, and the partition switching device 5 is used to drive the partition 4 to switch between the defective product collection position and the sample collection positio...

Embodiment 2

[0038] The sheet material defective product of embodiment 2 and sample separation collection device such as Figure 4 to Figure 5As shown, the difference between the separation and collection device and Embodiment 1 is that: the partition 4 is provided with a rotating shaft, and the partition swing mechanism 6 includes a crank linkage mechanism, and the crank 6a of the crank linkage mechanism is connected to the rotation shaft. Connected, the connecting rod 6b of the crank-link mechanism is connected with the telescopic device 6c. In this embodiment, the telescopic device 6c is an air cylinder. The telescopic movement of the telescopic device 6c is converted into the rotational movement of the rotating shaft through the crank-link mechanism, thereby driving the partition 4 to swing between the defective product collection position and the sample collection position.

Embodiment 3

[0040] The sheet material defective product of embodiment 3 and sample rejecting device such as Image 6 As shown, the rejecting device includes a transmission mechanism 7, a rejecting channel 8, a rejecting mechanism and the separation and collection device of Embodiment 1, the rejecting channel 8 includes a gap on the transport mechanism 7, and the rejecting mechanism is located above the rejecting channel 8, The rejecting mechanism is used to remove sheet materials downward from the rejecting channel 8 , the separation and collection device is located below the rejecting channel 8 and the sheet material inlet of the separation box 1 is facing the rejecting channel 8 .

[0041] The rejecting mechanism can be used not only for rejecting defective products, but also for sampling and rejecting. The rejected flake materials fall into the separation box 1 from the rejecting passage 8, and then through the separation action of the separation box 1 described in Embodiment 1, The de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com