Process method for preparing cyclopropyl methyl ketone

A technology of cyclopropyl methyl ketone and process method, which is applied to cleaning methods and utensils, preparation of carbon-based compounds, preparation of heterocyclic compounds, etc., can solve the problems of high cost, low purity, complicated reaction methods, etc., and achieves reduction of raw materials. and separation cost, high purity, reducing the effect of excessive deformation and collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

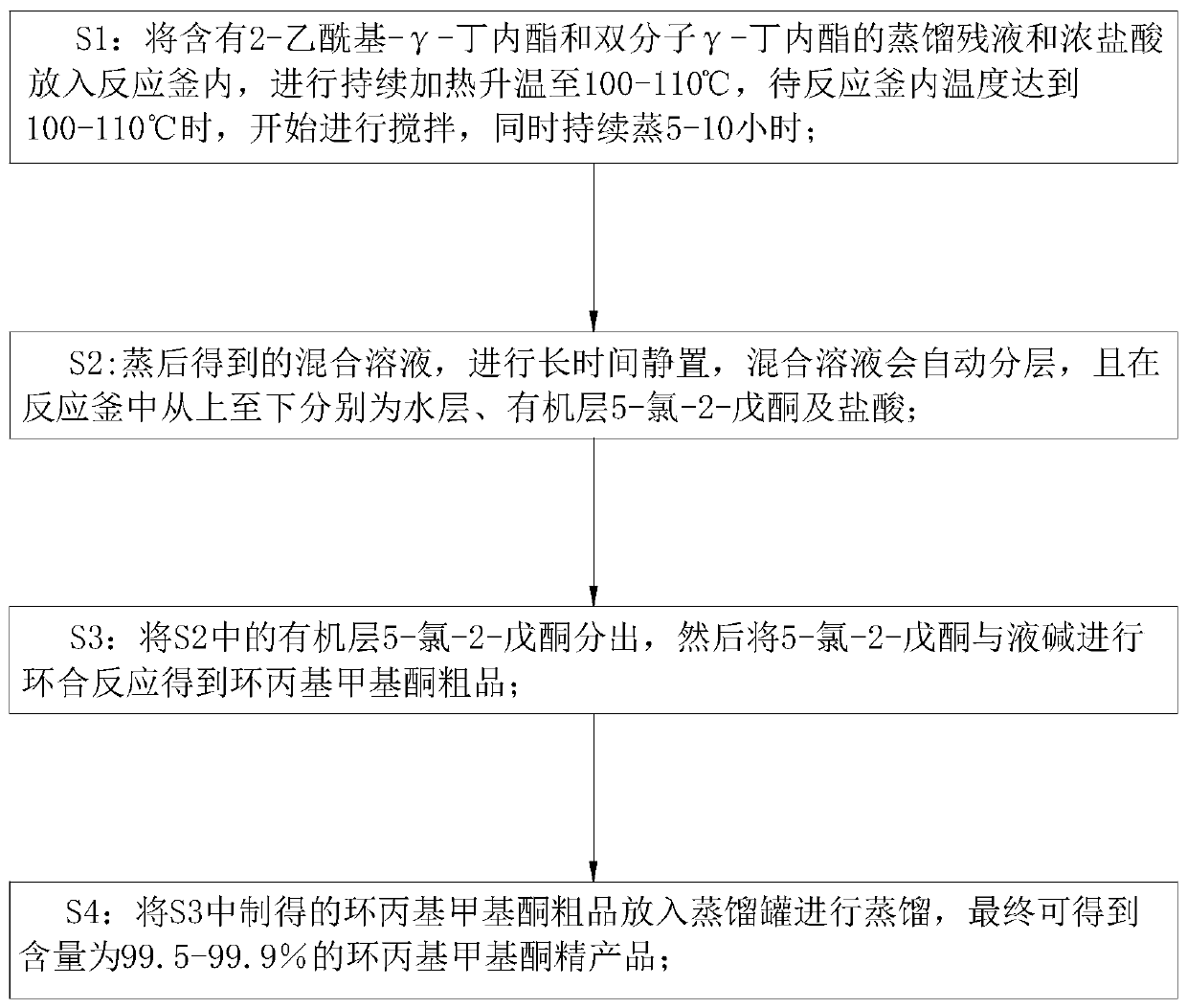

Method used

Image

Examples

Embodiment approach

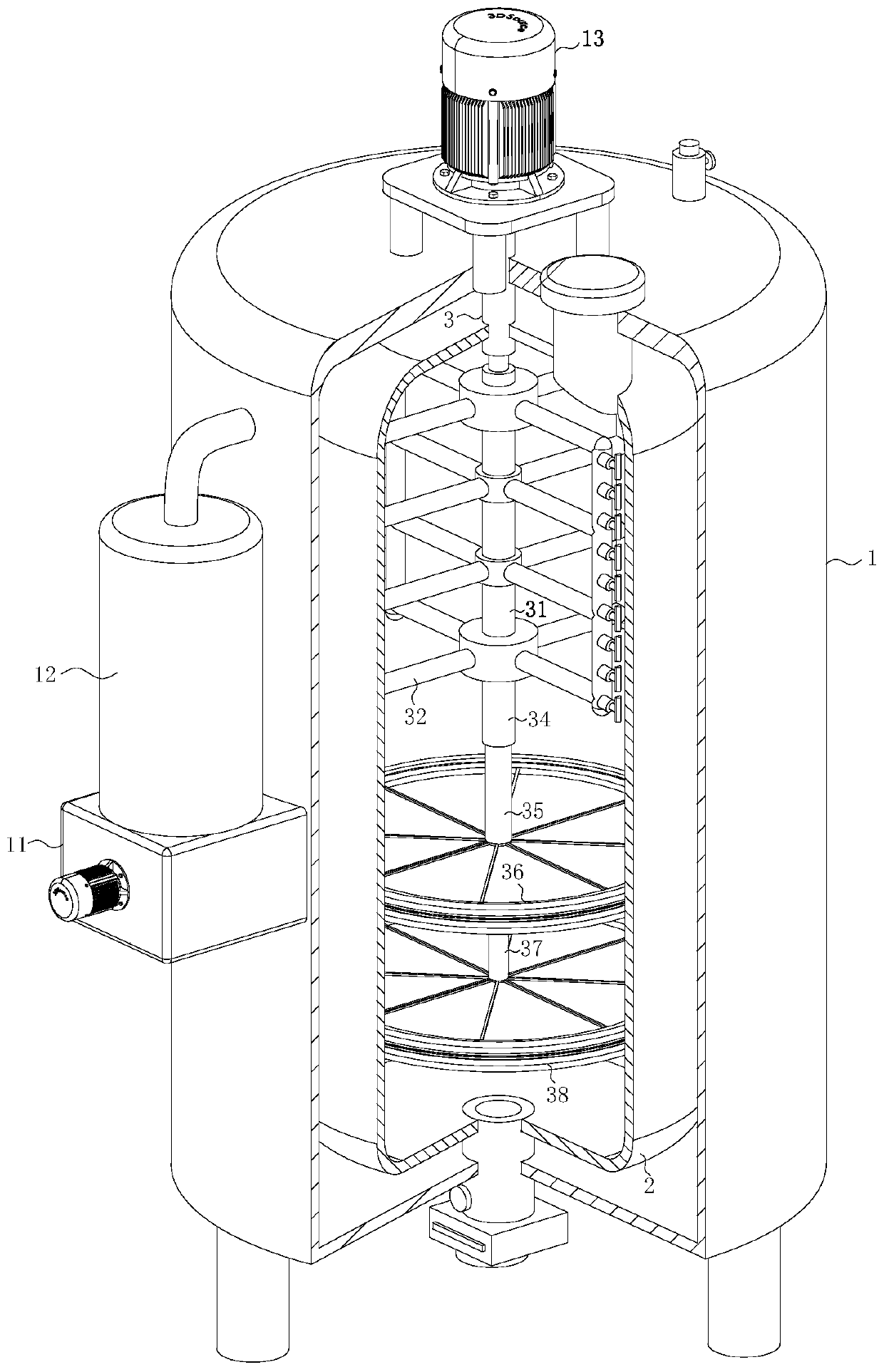

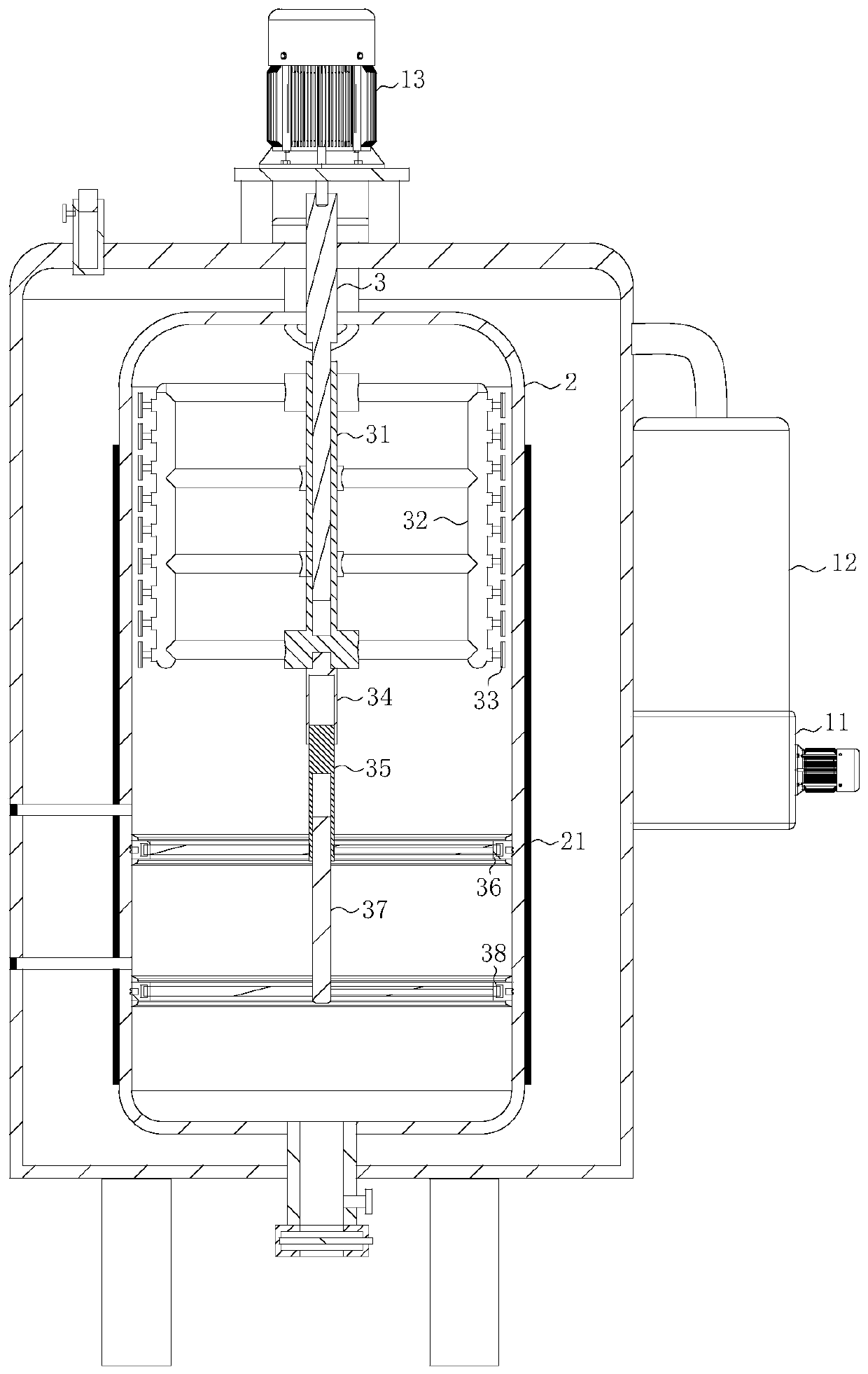

[0035] As an embodiment of the present invention, the first baffle plate 36 is designed in a circular structure, and the outer arc surface of the first baffle plate 36 is connected to the inner arc surface of the reaction tank 2 by sliding up and down; Evenly arranged sealing film 22 is arranged between the inner arc surface of the first baffle plate 36 and the third moving column 35, and the sealing film 22 is a fan-shaped structure design; the positions between any adjacent two sealing films 22 are fixed A rotating support plate 23 is connected; a head plate 24 and a tail plate 25 are respectively fixedly connected between two adjacent sealing films 22; the third moving column 35 is provided with a rotation groove at the position of the rotating support plate 23 , and the rotating support plate 23 and the first plate 24 are both slidably connected in the rotating groove, the inner arc surface of the first baffle 36 is provided with a stepped groove, and the rotating supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com