Independent circulating cleaning system for reuse cups

A cleaning system and cleaning machine technology, applied in the field of reusable cup cleaning, can solve the problems of high cost, high cost, and lack of standardized cleaning process, etc., to achieve the effect of guaranteeing the cleaning effect and increasing the cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

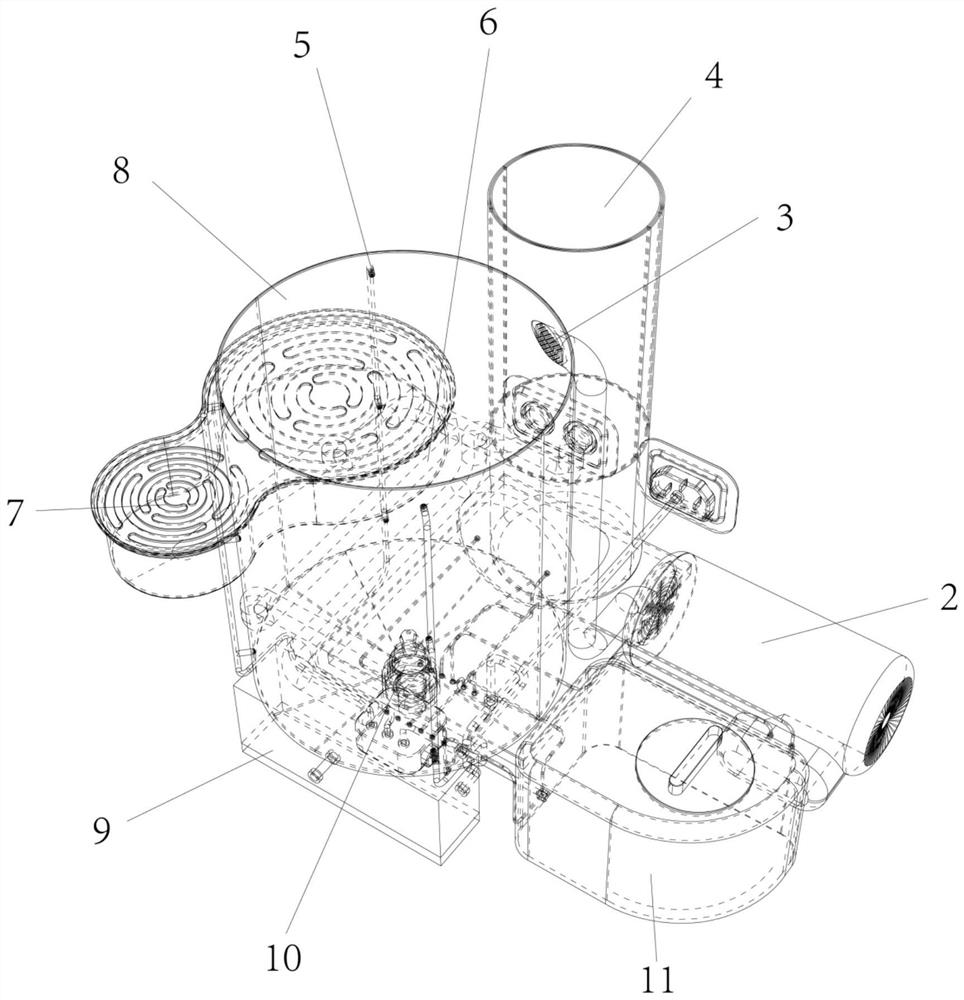

[0028] An independent circulating cleaning system for reusable cups, comprising a main body 1 of a washing machine and a main body 14 of a reusable cup, the upper surface of the main body of the washing machine 1 is fixedly equipped with a hot air blower 2, and the surface of the hot air blower 2 is provided with a cleaning chamber 8. Place the reusable cup body 14 inside the cleaning chamber 8 to clean the reusable cup body 14. The outer wall of the cleaning chamber 8 is provided with a side wall water outlet 5, which can be used for cleaning Clean water is added to the inside of the cavity 8, and an air outlet 3 is arranged on the upper right side of the side wall water outlet 5. After the hot air blower 2 heats the wind, it is sprayed from the air outlet 3 to heat and dry the reusable cup body 14. Take out the moisture on the surface of the reusable cup body 14 . The upper surface of the cleaning machine main body 1 is fixedly installed with a telescopic rod 4 above the hot...

Embodiment 2

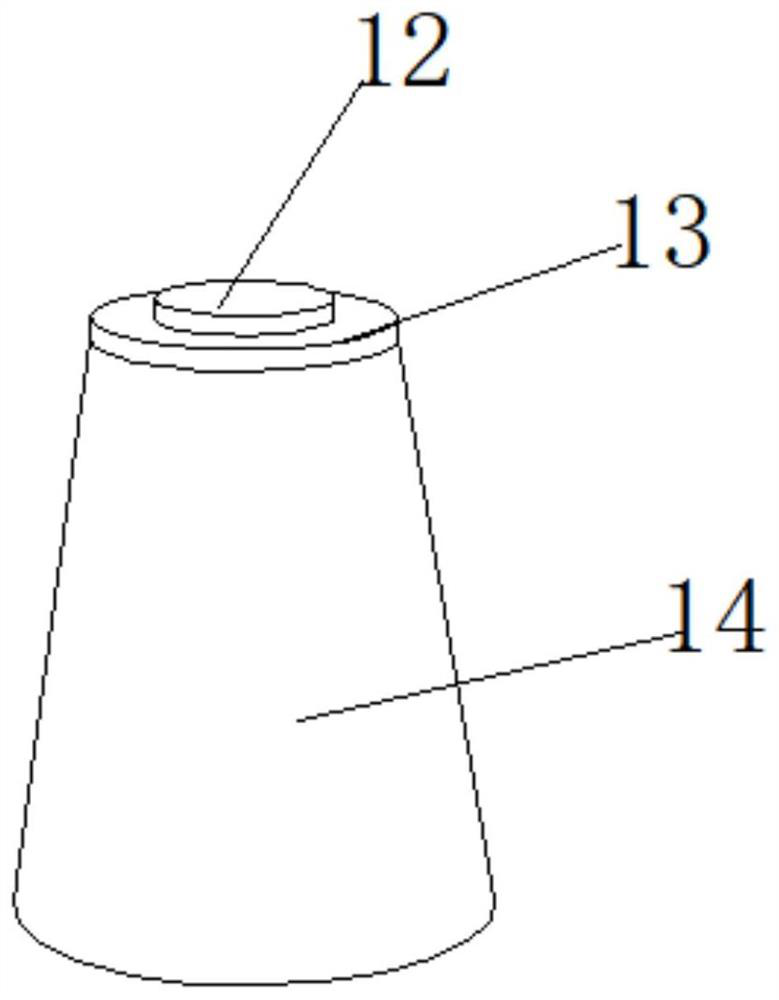

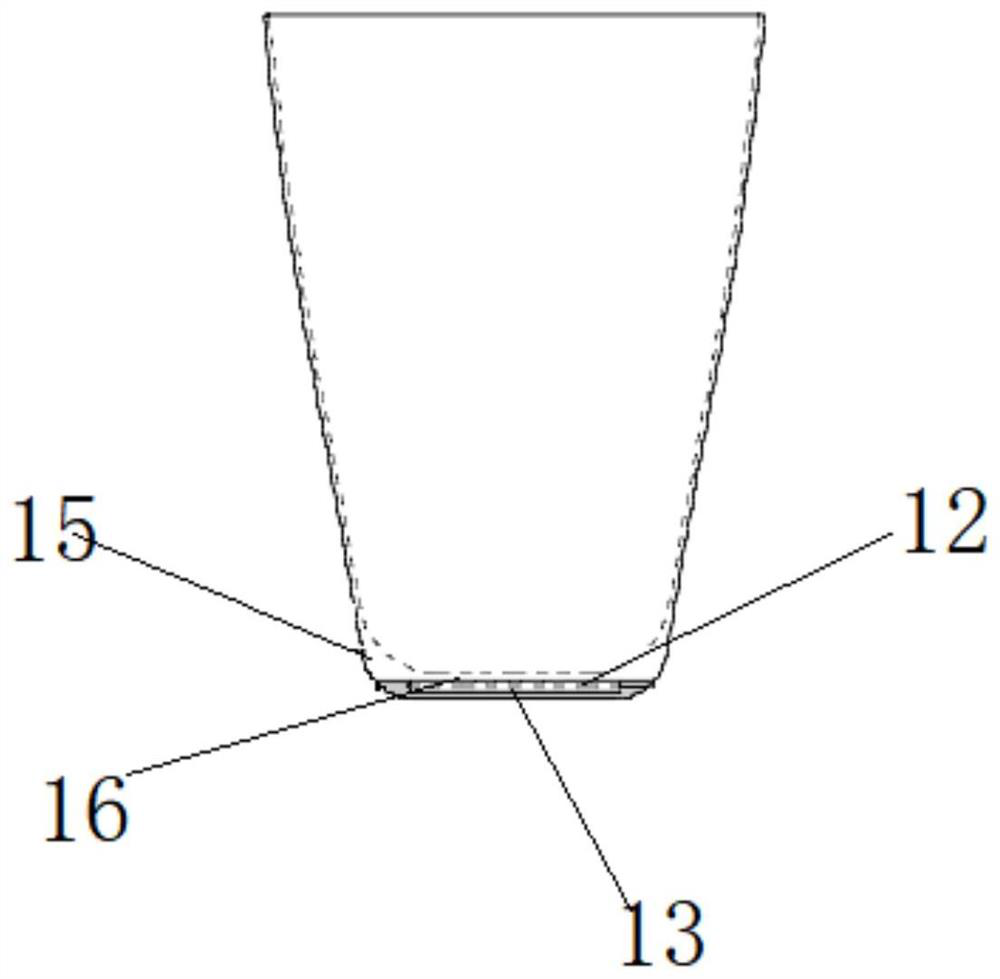

[0033] A reusable cup body 14 is placed above the filter screen 7, the bottom of the reusable cup body 14 is fixedly connected with a cup bottom 13, and the outer surface of the cup bottom 13 is fixedly equipped with a snap-in strip 12, and the snap-in strip 12 cooperates with the clamping mechanism 16 to clamp and fix the reusable cup body 14 when stacking the screws. When in use, the cup bottom 13 at the bottom of the reusable cup body 14 at the bottom can be fixed by the suction cup at the top of the cleaning machine main body 1. After the cup bottom 13 is fixed and absorbed by the suction cup, it will not easily fall and move, which increases the stability of the cleaning device during cleaning. At the same time, using the suction cup to fix the cup bottom 13 is also more convenient and fast, and is easy to operate.

[0034] The exterior of the reusable cup body 14 is provided with a metal cup body 15 , and the bottom of the metal cup body 15 is fixedly equipped with a lock...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com