Board strength detection device for desk drawer production

A technology of strength detection and drawer, which is applied in the direction of measuring device, using a stable bending force to test the strength and strength characteristics of materials, can solve the problems of not being able to fix the wooden board, consume a lot of time and effort, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

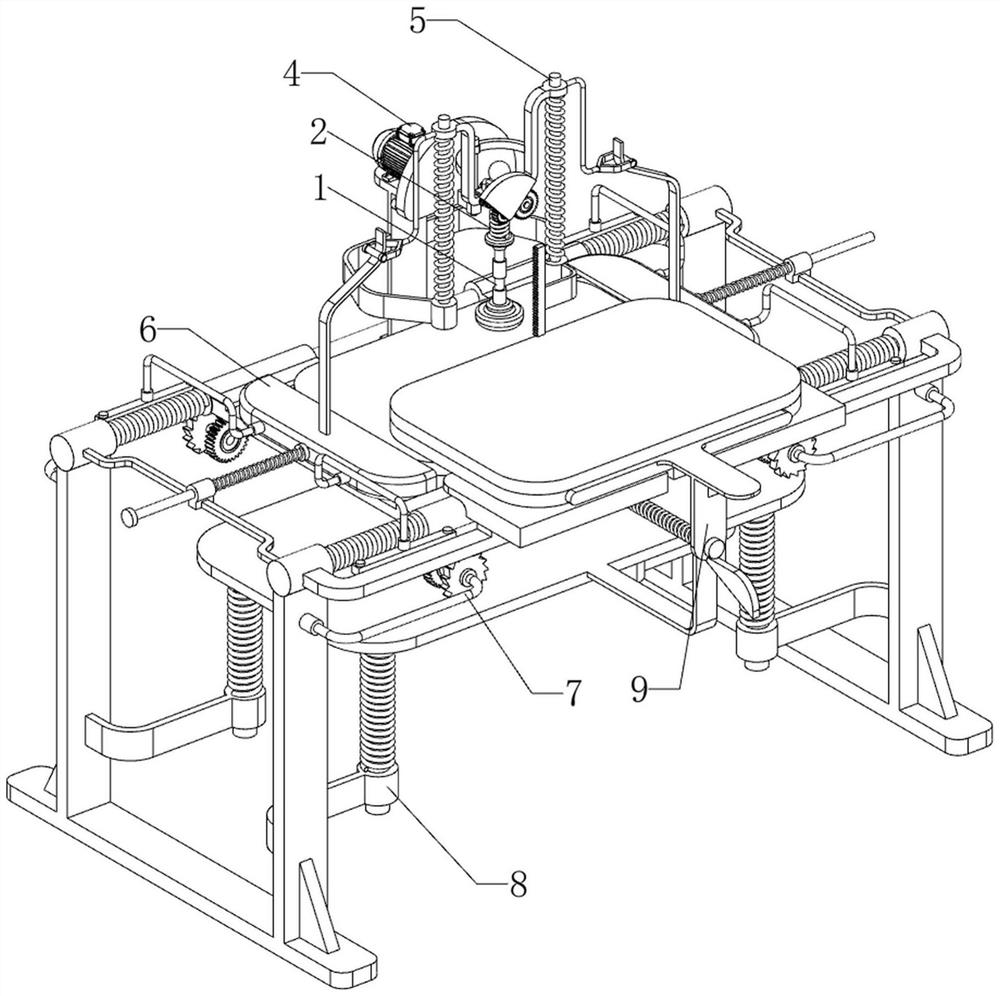

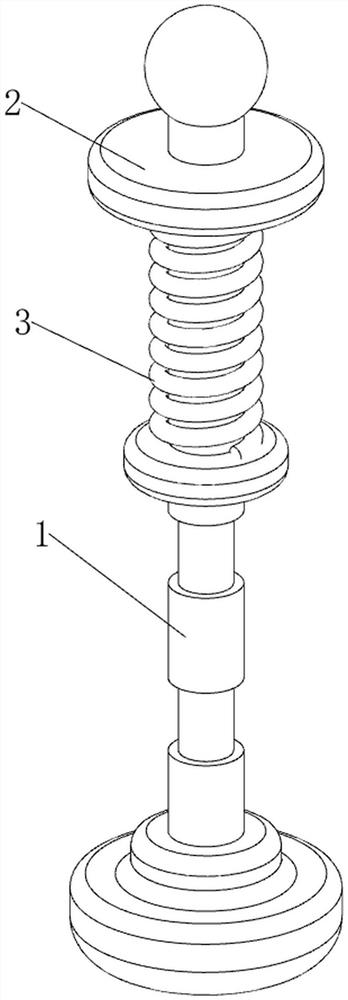

[0066] A panel strength detection device used in the production of desk drawers, such as Figure 1-Figure 5 As shown, it includes a detection rod 1, a slider 2, a first spring 3, a driving mechanism 4 and a detection mechanism 5. The driving mechanism 4 is provided with a detection mechanism 5, and the detection mechanism 5 is provided with a slider 2. The middle part of the slider 2 The sliding type is provided with a detection rod 1, and a first spring 3 is wound around the upper part of the detection rod 1, and the two ends of the first spring 3 are respectively connected with the detection rod 1 and the slider 2.

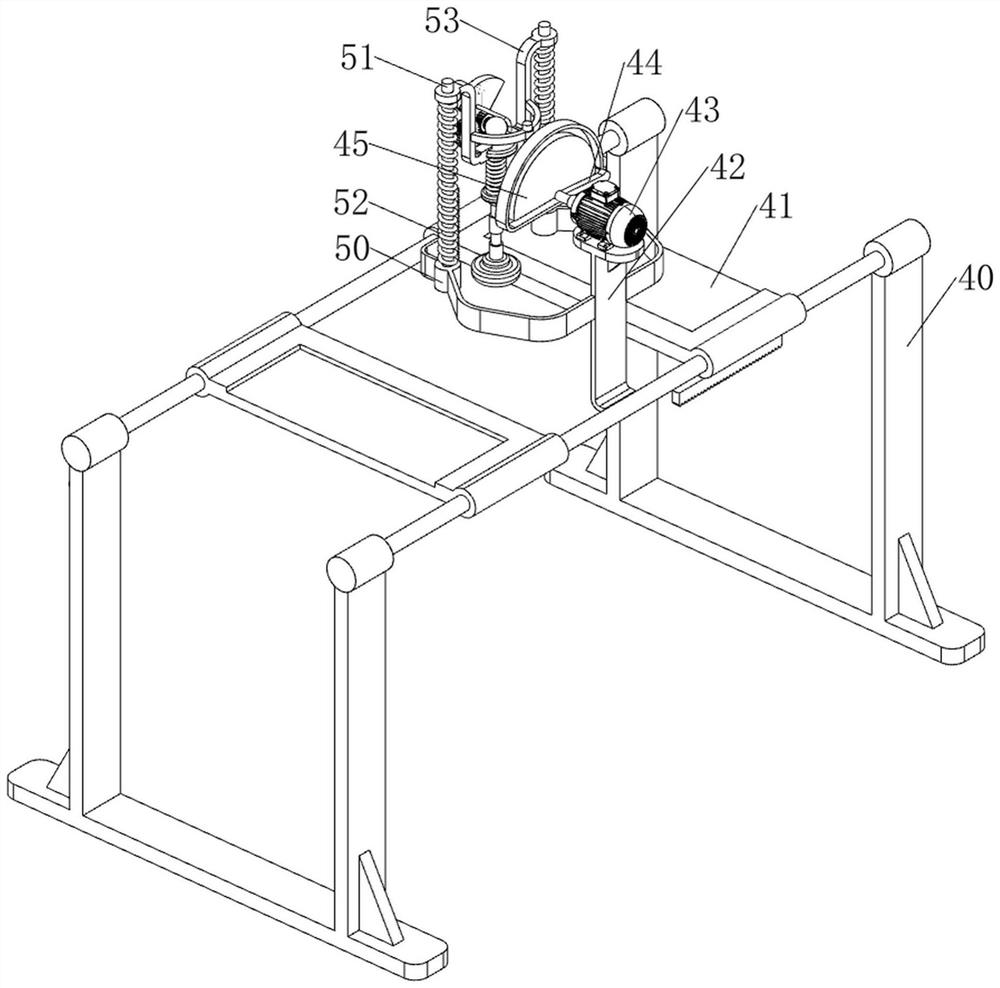

[0067] Drive mechanism 4 comprises support frame 40, discharge plate 41, mounting plate 42, servo motor 43, rotating rod 44 and slide rail 45, support frame 40 top left and right symmetrical sliding type is provided with discharge plate 41, support frame 40 top rear Side center is provided with mounting plate 42, and mounting plate 42 tops are provided with serv...

Embodiment 2

[0071] On the basis of Example 1, such as figure 1 , Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, a clamping mechanism 6 is also included, and the clamping mechanism 6 includes a first fixed sleeve 60, a slide bar 61, a third spring 62, a splint 63, a special-shaped plate 64 and a pressure bar 65, and the upper part of the support frame 40 is symmetrically arranged. There is a first fixed sleeve 60, the first fixed sleeve 60 is located at the outside of the discharge plate 41, the middle part of the first fixed sleeve 60 is slidingly provided with a slide bar 61, the inside of the slide bar 61 is provided with a splint 63, and the slide bar 61 is wound There is a third spring 62, the two ends of the third spring 62 are respectively connected with the first fixed sleeve 60 and the clamping plate 63, the middle of the top of the clamping plate 63 is provided with a special-shaped plate 64, and the outside of the connecting plate 53 is provided with a pressing bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com