Simple adjustable bench clamp

An adjustable, vise technology, used in vices, manufacturing tools, etc., can solve problems such as poor clamping adaptability, and achieve the effects of stable clamping, high clamping quality and a wide range of equipment applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

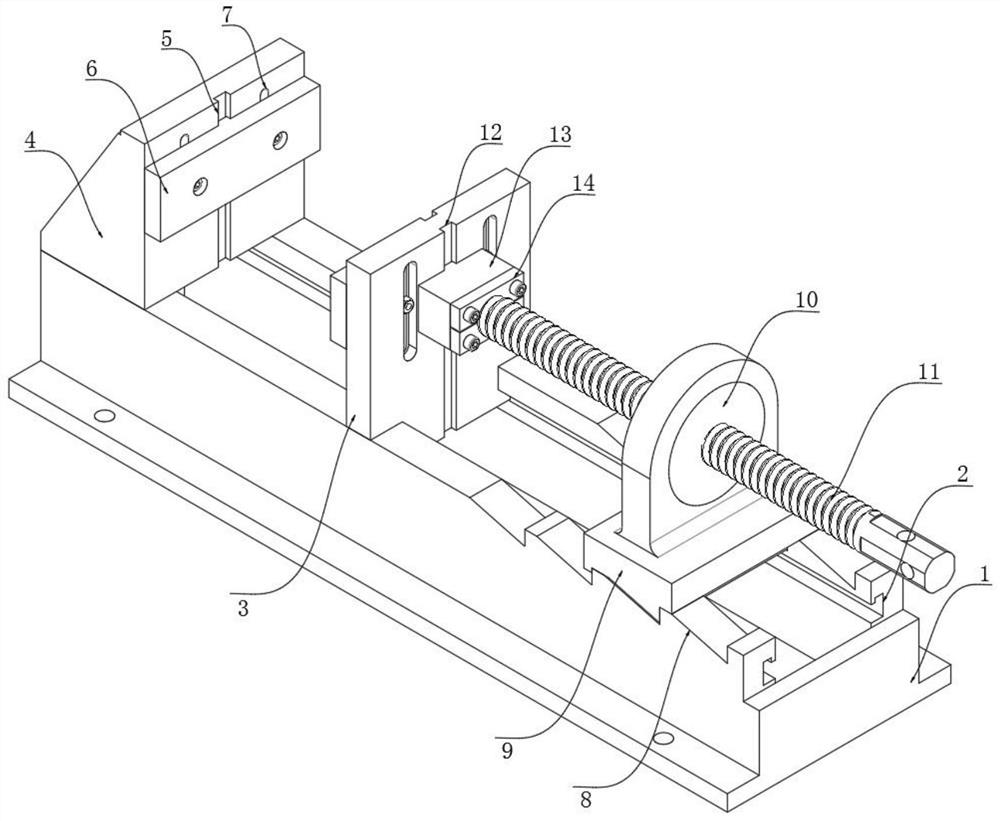

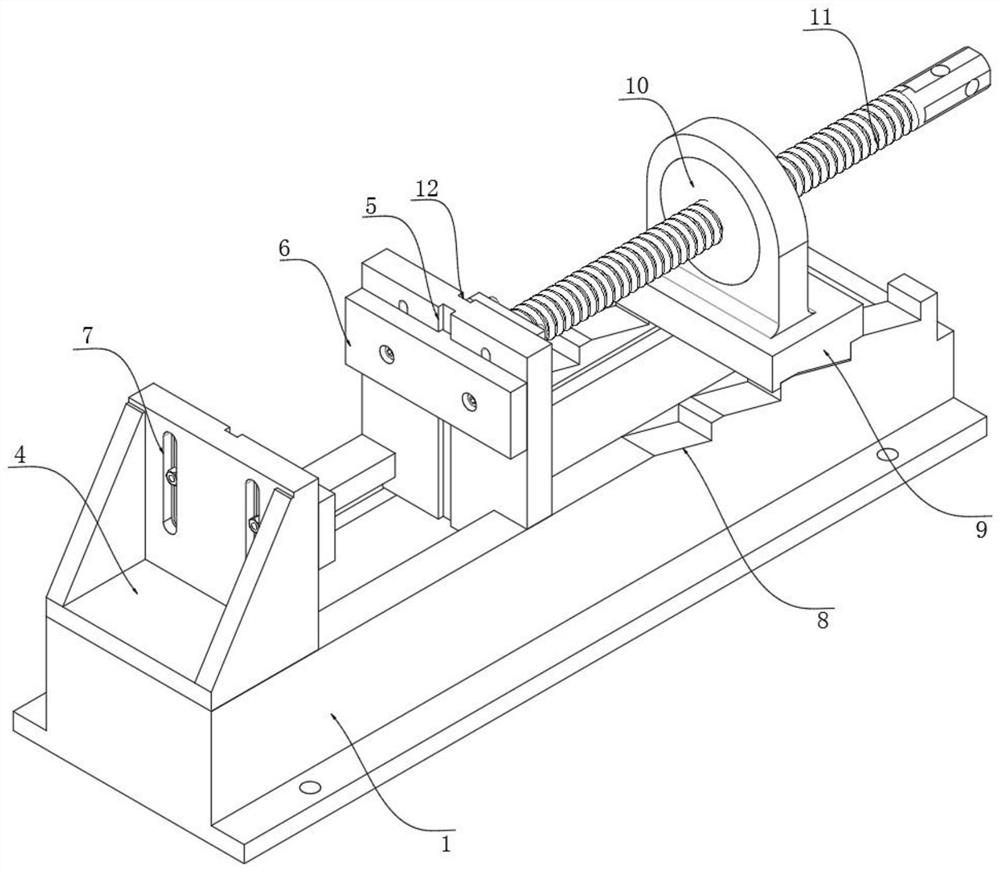

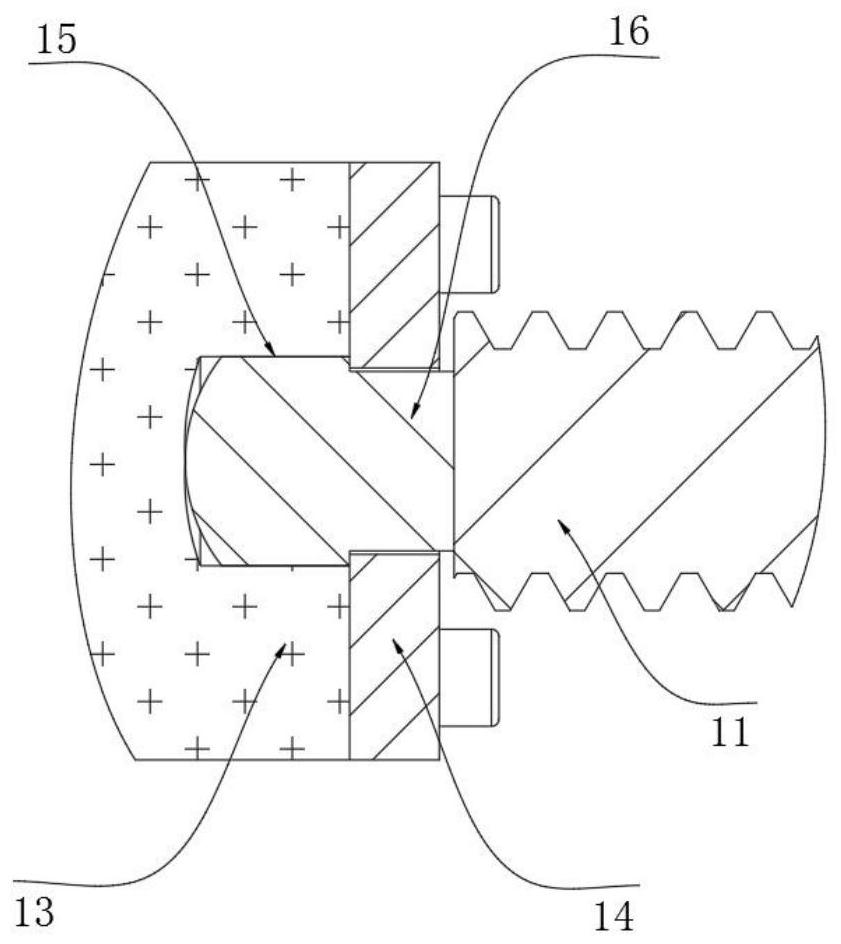

[0026] refer to Figure 1-3 , a simple adjustable vise, including a base 1, the side wall of the base 1 is provided with a chute 2, the inner wall of the chute 2 is slidably connected with a moving backing plate 3, the upper end of the base 1 is fixed with a fixed backing plate 4, and the moving backing The side walls of the plate 3 and the fixed backing plate 4 are equipped with a positioning and clamping mechanism, and the upper end of the base 1 is provided with a tooth socket 8, and the upper end of the tooth socket 8 is offset by a supporting tooth block 9, and the upper end of the supporting tooth block 9 is fixed with an adjustable support 10. The side wall of the adjustment support 10 is threadedly connected with a propulsion screw 11 , and the end of the propulsion screw 11 is connected with a propulsion coupling mechanism.

[0027] The positioning and clamping mechanism includes balance grooves 5 opened on the side walls of the movable backing plate 3 and the fixed b...

Embodiment 2

[0032] refer to Figure 4-5The difference between this embodiment and Embodiment 1 is that the advancement process is improved. The inner wall of the base 1 is connected with a screw 18 for rotation, and the side wall of the screw 18 is threaded with a slide plate 22. The movement of the slide plate 22 will drive the wire The rotation of bar 18, the upper end of slide plate 22 is fixed with hydraulic box 23, and the inner wall of hydraulic box 23 is sealed and slidably connected with push plate 27, and push block 13 penetrates the side wall of hydraulic box 23 and is fixed with the side wall of push plate 27, pushes The plate 27 and the inner wall of the hydraulic box 23 are jointly fixed with a drive spring 26, the side wall of the hydraulic box 23 is fixed with an extrusion box 24, and the inside of the extrusion box 24 is provided with a positioning and advancing mechanism, and the inner wall of the synchronous groove 12 is slidingly connected with a force Block 25, the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com