Pile hole diameter detection device for supervision

A detection device and pile hole technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of complex equipment, high environmental light requirements, large errors, etc., to achieve accurate measurement, realize roundness measurement, The effect of easy reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

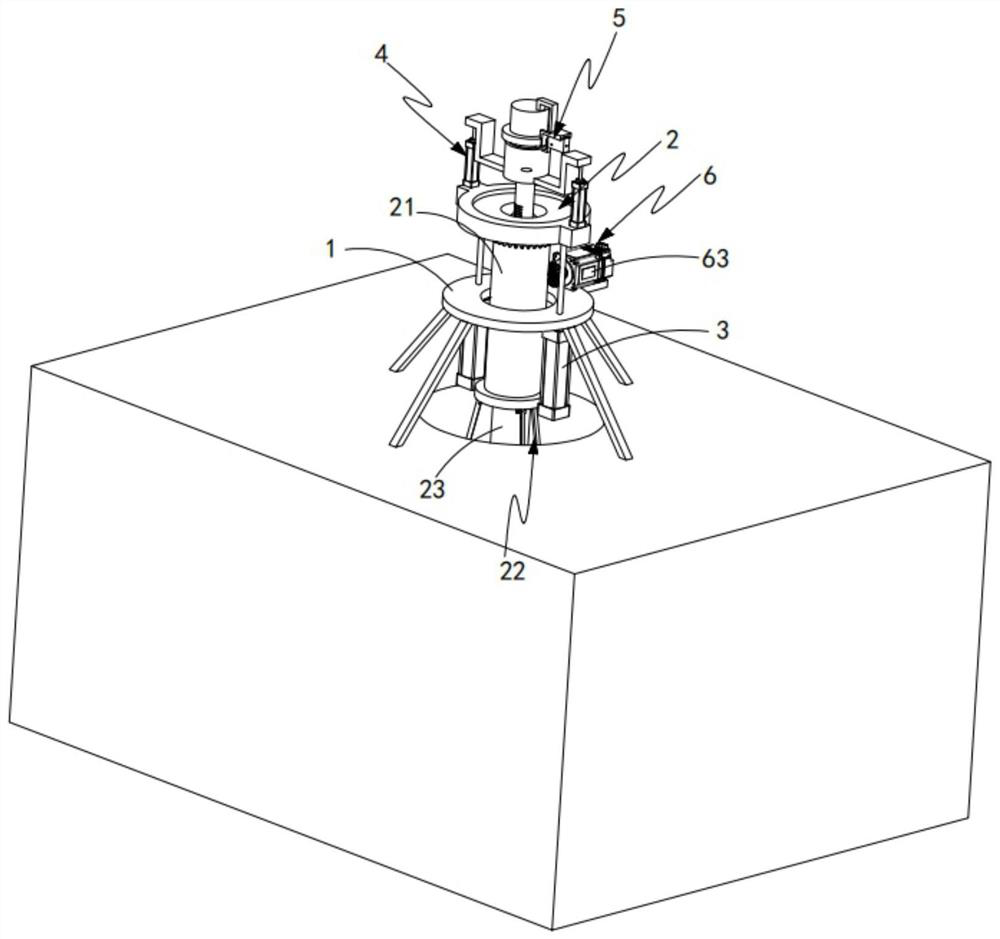

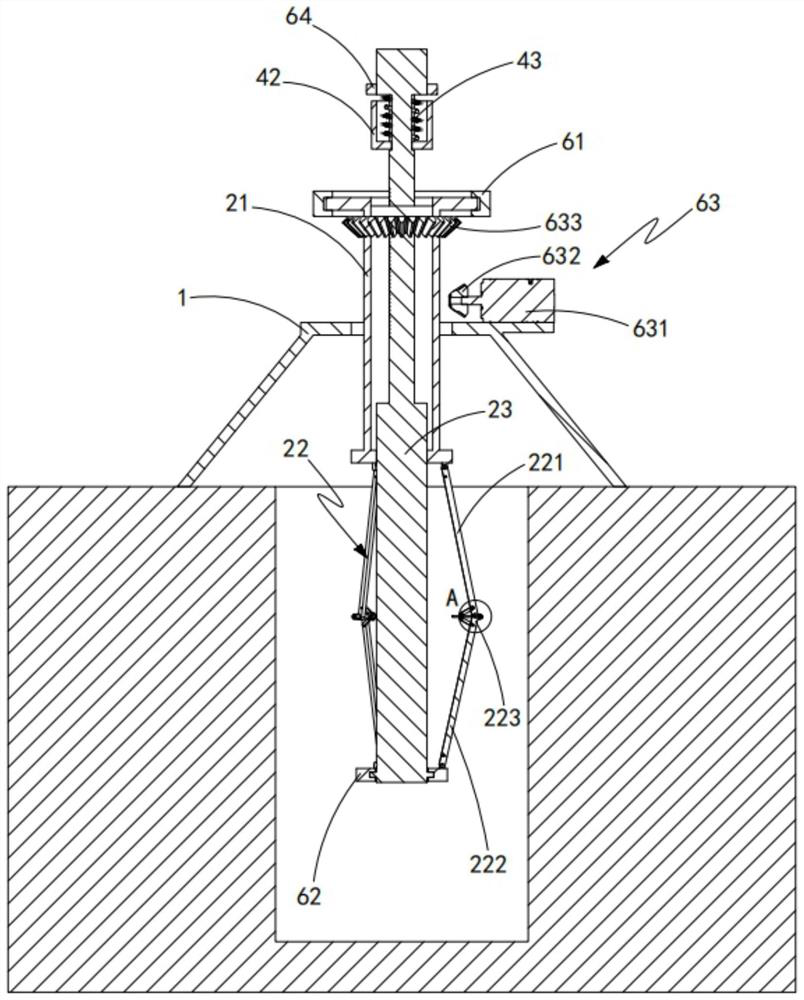

[0036] Such as Figures 1 to 3 As shown, a pile hole diameter detection device for supervision includes a workbench 1 erected above the pile hole, and is characterized in that it also includes a diameter measuring component 2, and the diameter measuring component 2 extends into the pile hole to detect the diameter of the pile hole. diameter, the diameter measuring assembly 2 includes:

[0037] Outer cylinder 21;

[0038] Outer support unit 22, the outer support unit 22 is arranged at the bottom of the outer cylinder 21; and

[0039] Inner cylinder 23, the inner cylinder 23 slides relative to the outer cylinder 21, the inner cylinder 23 moves to drive the outer support unit 22 to support the hole wall of the pile hole, and measure the inner cylinder 23 relative to the outer cylinder The distance moved by 21 directly obtains the diameter of the pile hole.

[0040] It should be noted that when measuring the diameter of the pile hole, the inner cylinder 23 rises so that the out...

Embodiment 2

[0051] Such as Figures 4 to 6 As shown, the parts that are the same as or corresponding to the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below: the differences between the second embodiment and the first embodiment at:

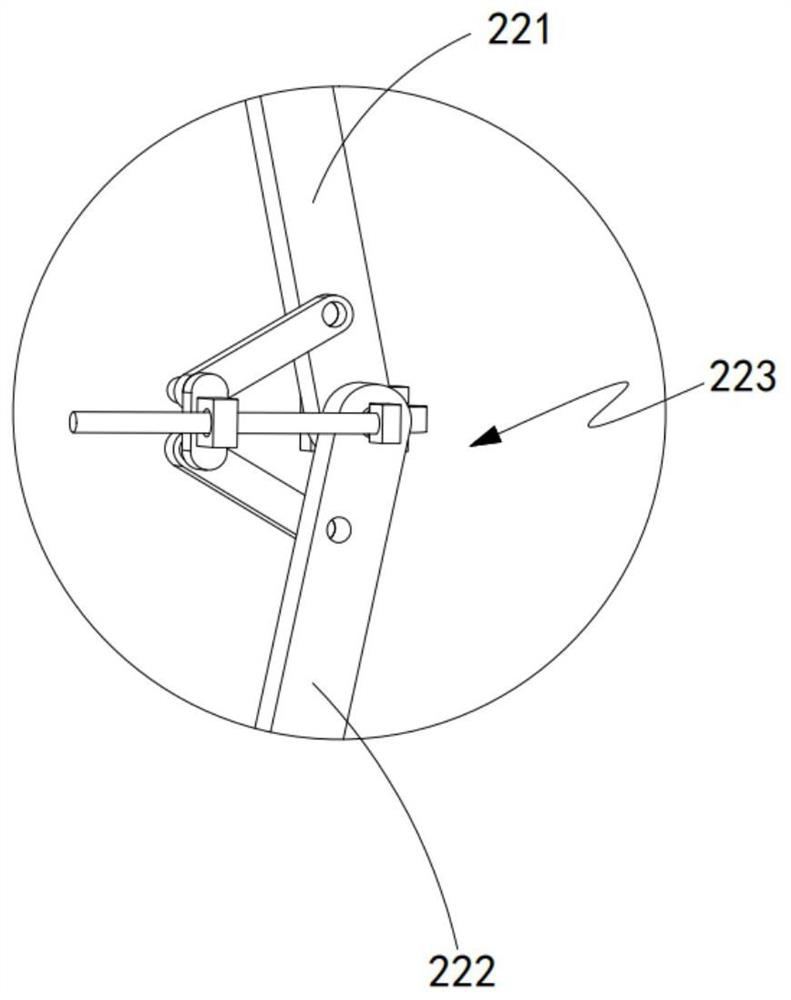

[0052] In this embodiment, a roundness measurement assembly 6 is also included, and the roundness measurement assembly 6 includes a collar one 61, a collar two 62 and a rotation drive unit 63, and the collar one 61 is sleeved on the outer cylinder 21, the collar 2 62 is set at the bottom of the outer support unit 22 and is sheathed on the bottom end of the inner cylinder 23, the rotation drive unit 63 drives the outer cylinder 21 to rotate, the The outer support unit 22 fits the inner wall of the pile hole to measure its roundness.

[0053] It should be noted that the detection contact part 223 of the outer support unit 22 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com