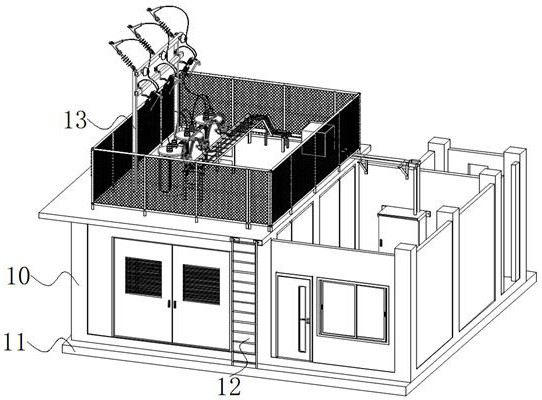

A compact transformer and a substation equipped with it

A transformer and compact technology, applied in the field of transformers, can solve the problems of inconvenient transformer oil to dissipate heat to the iron core and windings, reduce the probability of contact between insulating oil and air, increase the degree of magnetic loss and copper loss, etc. The effect of prolonging the effect, reducing iron loss, and reducing the aging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

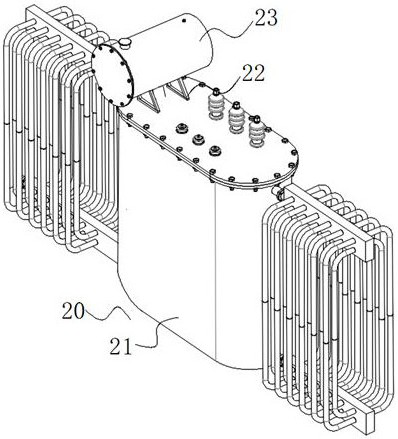

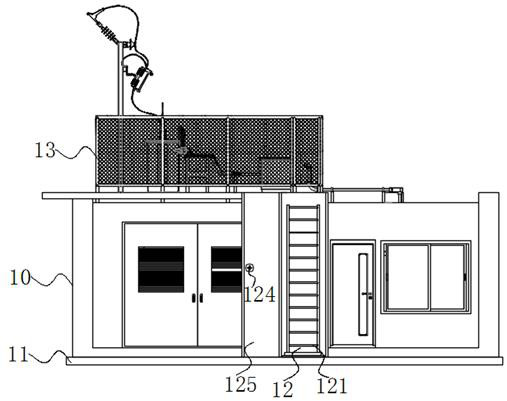

[0036] A compact transformer, based on figure 2 , Figure 9-Figure 11 As shown, a transformer body 20 is included, and the transformer body 20 includes an oil tank 21, a support frame 22 and an oil conservator 23, the support frame 22 is installed at the bottom of the oil conservator 23, and the oil conservator 23 passes through the support frame 22 It is fixedly connected with the top of the oil tank 21, and the bottom end of the oil conservator 23 is connected with a communication pipe 28 through which the oil conservator 23 is connected with the oil tank 21 through the communication pipe 28. Both the oil tank 21 and the oil conservator 23 are equipped with There is transformer oil, and the temperature of the transformer oil inside the oil tank 21 is higher than that of the transformer oil inside the oil conservator 23, and the oil conservator 23 also includes a respirator 24, a connecting pipe 25, a glass pipe 26, an oil inlet pipe 27 and a ventilator. Air plug 29, the re...

Embodiment 2

[0039] A compact transformer, based on Figure 9 and Figure 12 As shown, on the basis of Embodiment 1, the inside of the second capsule bag 302 is provided with a through hole, the inside of the second capsule bag 302 is installed with a bearing plate 305, and the bearing plate 305 passes through the through hole Transversely runs through the second capsule bag 302, and both sides of the inner wall of the oil conservator 23 are provided with a third limiting groove 231, and the bearing plate 305 is slidably connected with the oil conservator 23 through the third limiting groove 231. The force bearing plate 305 is designed in an arc shape, and the arc shape of the force bearing plate 305 is adapted to the oil conservator 23 .

[0040] In this embodiment, setting the bearing plate 305 in the first capsule bag 301, the second capsule bag 302 and the third capsule bag 303 can reduce the impact of the high pressure generated by the sloshing of the transformer oil in the oil tank ...

Embodiment 3

[0042] A compact transformer, based on Figure 9-Figure 10 As shown, on the basis of Embodiment 1 or Embodiment 2, a floating ball 261 is placed inside the glass tube 26, and a warning frame 262 is opened on the upper right side of the glass tube 26, and the warning frame 262 and the glass The tube 26 is rotatably connected, and the warning frame 262 is connected through the glass tube 26. The sealing between the glass tube 26 and the warning frame 262 is good, and the warning frame 262 is arranged in a gourd shape. After turning the warning frame 262, the floating ball 261 that enters the inside of the warning frame 262 returns to the inside of the glass tube 26, thereby realizing the reuse of the floating ball 261. The right side of the bottom end of the warning frame 262 is fixedly connected to the weight block 263, The weight block 263 can facilitate the return of the warning frame 262 to its original position after rotation, thereby realizing the warning function of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com