Stable sand washer for mining machinery

A technology for sand washing machines and mines, applied in the field of sand washing machines, which can solve the problems of inconvenient periodic regulation work, inability to reduce amplitude frequency, and inability to install side-end positions, etc., so as to improve use efficiency, facilitate regulation work, and stabilize processing The effect of production work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

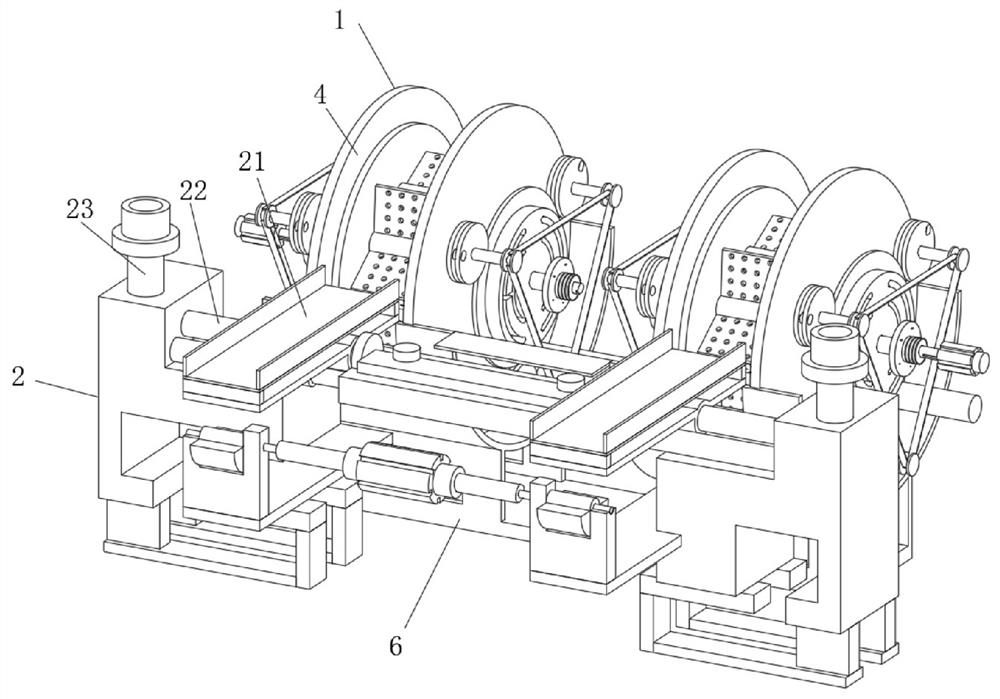

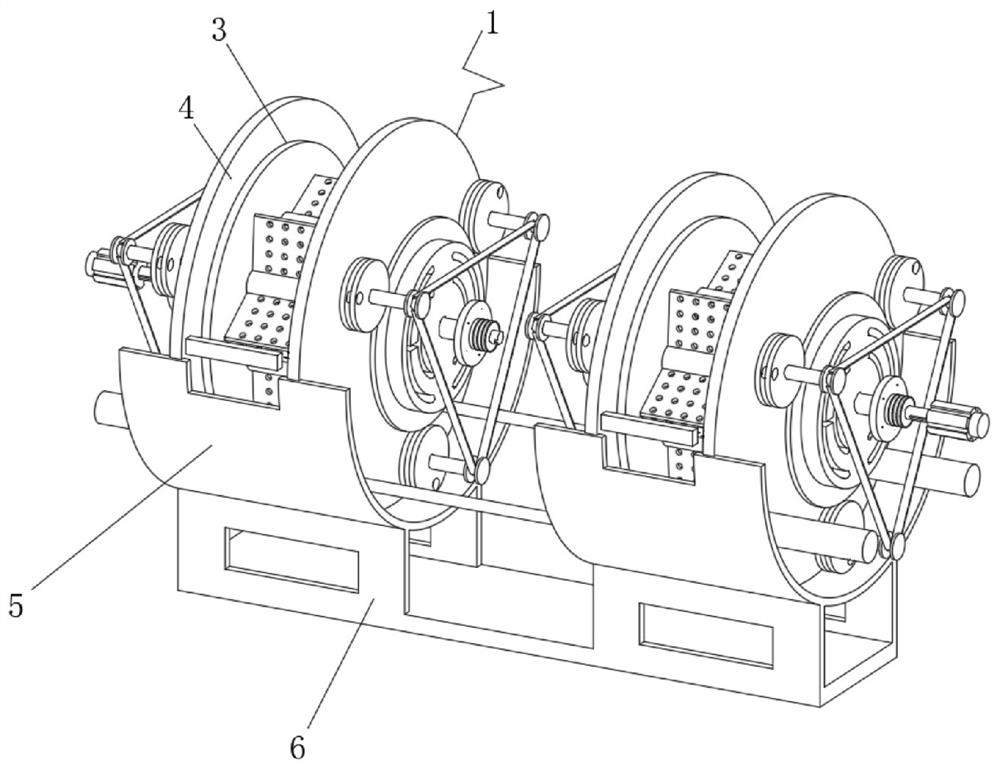

[0033] see Figure 1-7 , an embodiment provided by the present invention: a stable sand washing machine for mining machinery, including a sand washing device 1, the front end of the sand washing device 1 is connected with a conduction device 2, through the sand washing device 1 and the conduction device 2 connection settings can help to carry out the overall construction of the inner end, realize the overall connection production operation, and improve the overall installation and use performance;

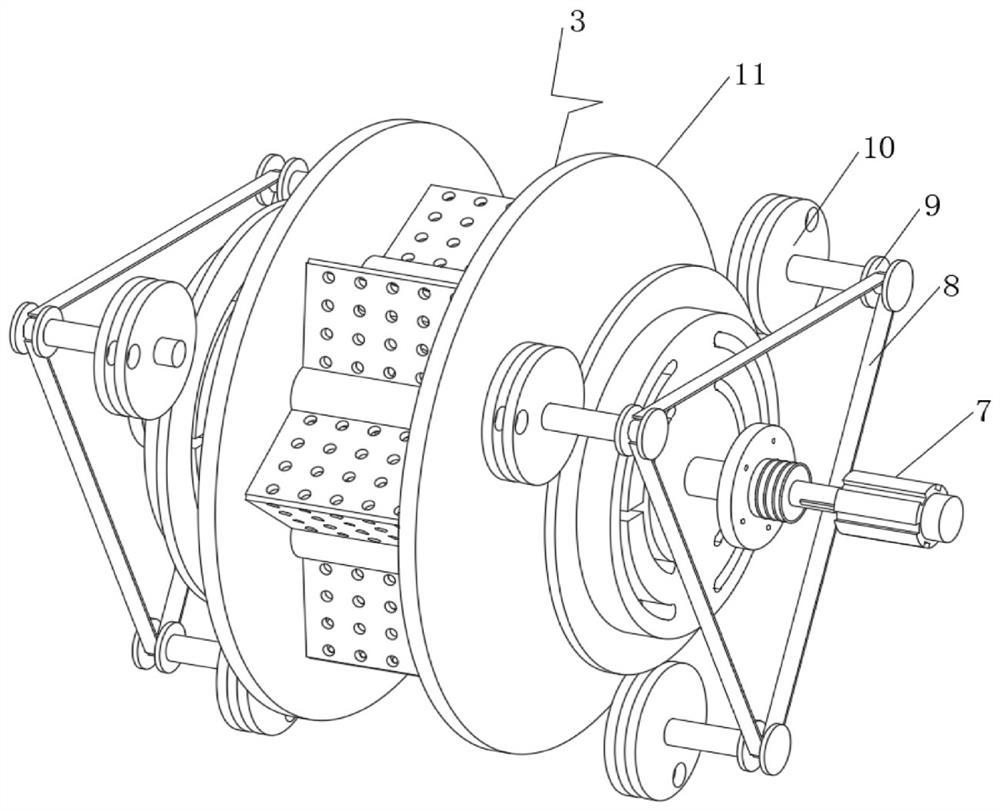

[0034] The sand washing device 1 includes a rotating structure 3, a communication pool 4, an arc-shaped baffle 5 and a base frame 6. The base frame 6 is located at the bottom of the inner end of the sand washing device 1. Fixed connection, the upper end position of the arc-shaped baffle 5 is fixedly connected with the communication pool 4, and the center position of the communication pool 4 is rotatably connected with a rotating structure 3, through the rotating structure 3, the co...

Embodiment 2

[0044] On the basis of Example 1, such as Figure 8 As shown, a water pipe 31 is fixedly connected to the top of the sand washing device 1 , and the water pipe 31 is arranged in communication with the outside world.

[0045] During the implementation of this embodiment, the user can connect the water pipe 31 with the outside world. Through the connection with the outside world, it can help to carry out the internal water intake work, realize the surface sprinkling operation, and help to perform the secondary cleaning work. The sand washing device 1 is discharged to realize reciprocating cleaning work, and the water pipe 31 is arranged on the communication pool 4 to realize the fixed connection of the top position.

[0046] Working principle: The user assembles and sets the sand washing device 1 and the conduction device 2 to realize mutual connection and setting, which helps to carry out the overall construction and setting work. The user first starts the double-head motor 25,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com