Preparation method of antibacterial chinlon fabric

An antibacterial and antibacterial brocade technology is applied in the field of preparation of antibacterial nylon fabrics, which can solve the problems of inconvenient periodic transmission connection work, inconvenience of stable limited connection, inconvenience of continuous dredging work, etc., and achieves good reproduction work, convenient transmission and connection work, Achieve smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

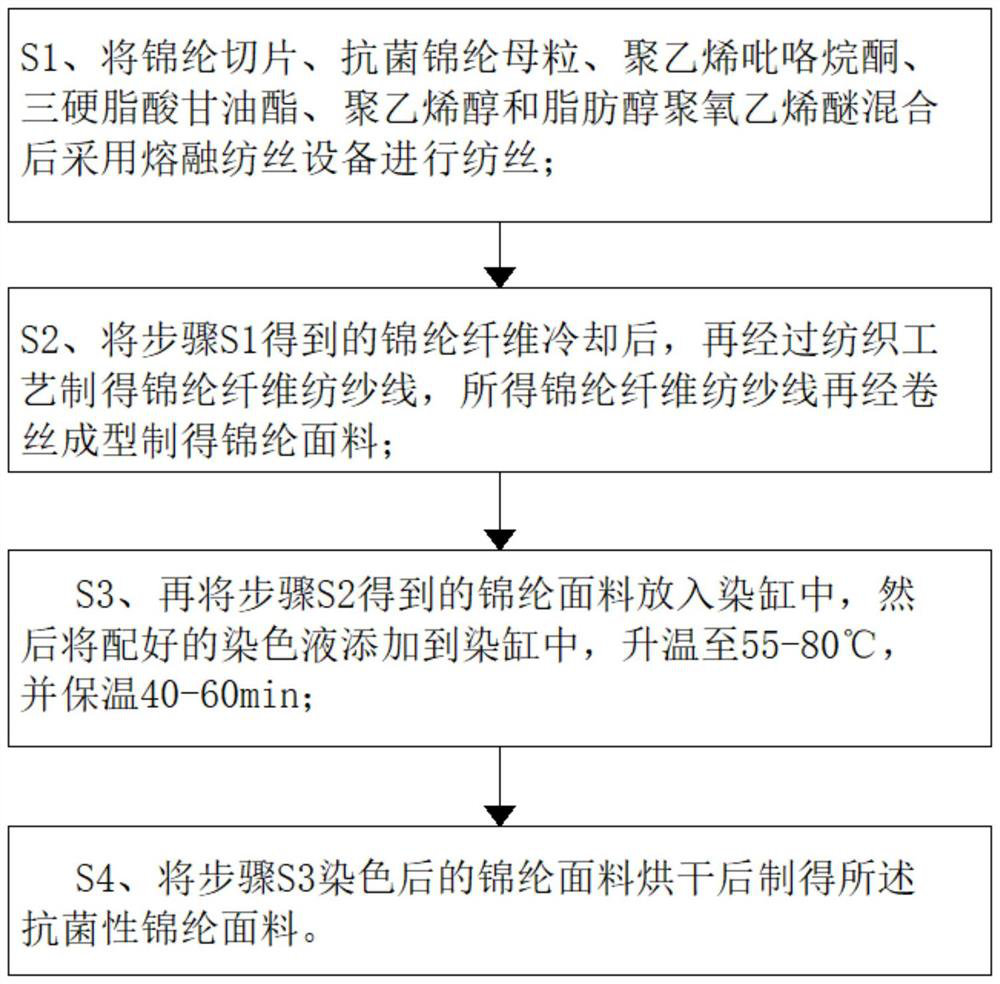

[0056] A preparation method of antibacterial nylon fabric, comprising the following steps:

[0057] S1. After mixing nylon chips, antibacterial nylon masterbatch, polyvinylpyrrolidone, glyceryl tristearate, polyvinyl alcohol and fatty alcohol polyoxyethylene ether, the melt spinning equipment is used for spinning;

[0058] S2. After cooling the nylon fiber obtained in step S1, the nylon fiber spun yarn is obtained through a textile process, and the obtained nylon fiber spun yarn is then coiled to form a nylon fabric;

[0059] S3, put the nylon fabric obtained in step S2 into the dyeing vat, then add the prepared dyeing solution into the dyeing vat, raise the temperature to 55 ° C, and keep it warm for 40 minutes;

[0060] S4, drying the nylon fabric dyed in step S3 to prepare the antibacterial nylon fabric.

[0061] An antibacterial nylon fabric, characterized in that its raw materials include: 100 parts of nylon chips, 7 parts of antibacterial nylon masterbatch, 35 parts of ...

Embodiment 2

[0063] A preparation method of antibacterial nylon fabric, comprising the following steps:

[0064] S1. After mixing nylon chips, antibacterial nylon masterbatch, polyvinylpyrrolidone, glyceryl tristearate, polyvinyl alcohol and fatty alcohol polyoxyethylene ether, the melt spinning equipment is used for spinning;

[0065] S2. After cooling the nylon fiber obtained in step S1, the nylon fiber spun yarn is obtained through a textile process, and the obtained nylon fiber spun yarn is then coiled to form a nylon fabric;

[0066] S3, put the nylon fabric obtained in step S2 into the dyeing vat, then add the prepared dyeing solution into the dyeing vat, raise the temperature to 70° C., and keep it warm for 50 minutes;

[0067] S4, drying the nylon fabric dyed in step S3 to prepare the antibacterial nylon fabric.

[0068] An antibacterial nylon fabric, characterized in that its raw materials include: 110 parts of nylon chips, 8 parts of antibacterial nylon masterbatch, 4 parts of p...

Embodiment 3

[0070] A preparation method of antibacterial nylon fabric, comprising the following steps:

[0071] S1. After mixing nylon chips, antibacterial nylon masterbatch, polyvinylpyrrolidone, glyceryl tristearate, polyvinyl alcohol and fatty alcohol polyoxyethylene ether, the melt spinning equipment is used for spinning;

[0072] S2. After cooling the nylon fiber obtained in step S1, the nylon fiber spun yarn is obtained through a textile process, and the obtained nylon fiber spun yarn is then coiled to form a nylon fabric;

[0073] S3, put the nylon fabric obtained in step S2 into the dyeing vat, then add the prepared dyeing solution into the dyeing vat, raise the temperature to 80° C., and keep it warm for 60 minutes;

[0074] S4, drying the nylon fabric dyed in step S3 to prepare the antibacterial nylon fabric.

[0075] An antibacterial nylon fabric, characterized in that its raw materials include: 130 parts of nylon chips, 9 parts of antibacterial nylon masterbatch, 4 parts of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com