Elastic pressing device for antenna processing

An elastic compression and antenna technology, applied in workpiece clamping devices, slot antennas, manufacturing tools, etc., can solve the problems of uneven compression, local overpressure or insufficient pressure, and become longer, and achieve stable clamping force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

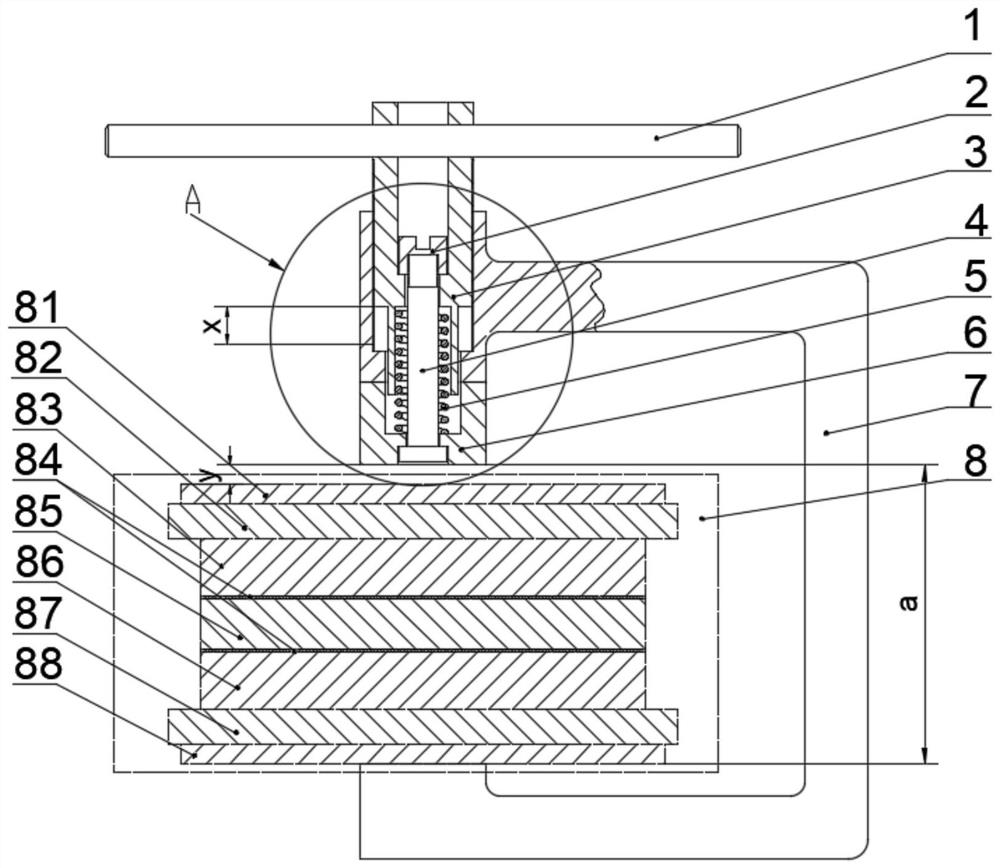

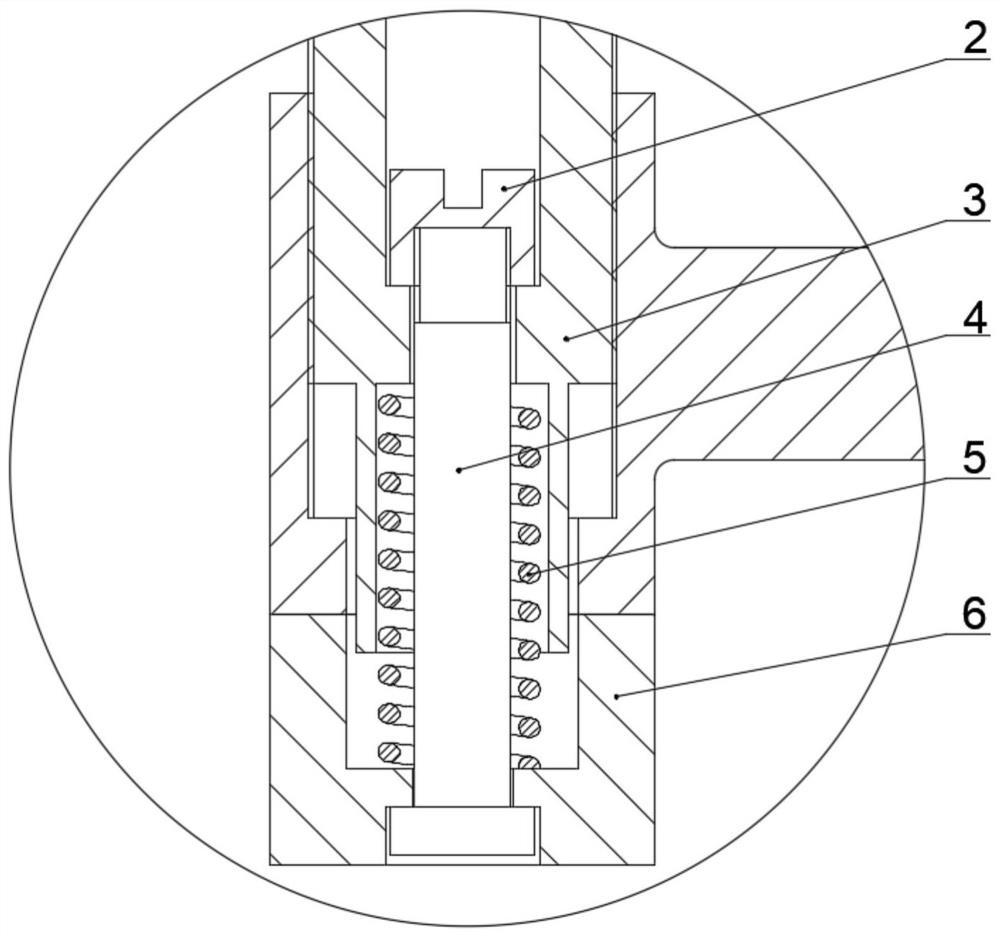

[0040] Such as figure 1 and figure 2 As shown, this embodiment provides an elastic pressing device for antenna processing, including: a C-shaped skeleton 7, an elastic pressing part and an operating part.

[0041] elastic pressing part, the elastic pressing part is screwed on the top of the C-shaped skeleton 7, the outer side wall of the elastic pressing part is provided with a scale, and the elastic pressing part is determined by the scale The screw-in depth determines the calibration pressure. The operating member is connected to one end of the elastic pressing member, and the operating member drives the elastic pressing member to move up and down.

[0042] Wherein the C-shaped frame 7 forms a clamping shape, so that the workpiece 8 to be welded can be put into the C-shaped frame 7, and the position of the elastic pressing part is changed by manually using the operating part, and the elastic pressing part is moved down to be connected with the welder. The top surface of ...

Embodiment 2

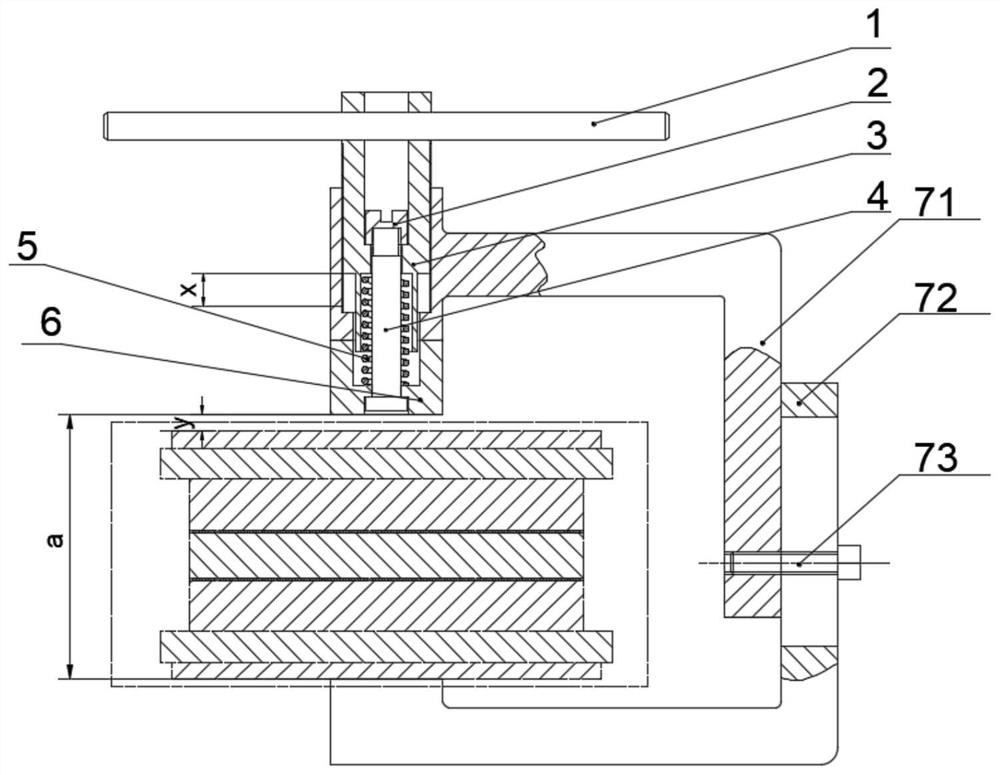

[0067] Such as image 3 As shown, this embodiment provides an elastic pressing device for antenna processing. The difference between this embodiment and Embodiment 1 is that the C-shaped frame 7 includes an upper frame 71 and a lower frame 72, and the upper frame 71 Located vertically above the lower frame 72, one end of the upper frame 71 is set opposite to one end of the lower frame 72 for clamping the workpiece, and the elastic pressing part is slidably connected to the upper frame 71 The other end of the upper frame 71 and the other end of the lower frame 72 are detachably connected. The structure of other parts of this embodiment is exactly the same as that of Embodiment 1.

[0068] Wherein, through the detachable connection of the upper frame 71 and the lower frame 72, the distance between the upper frame 71 and the lower frame 72 can be adjusted, and more workpieces 8 to be welded can be adapted to be clamped.

[0069] Preferably, in this embodiment, the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com