Industrial robot gripper storage device and using method thereof

A technology for industrial robots and storage devices, applied in tool storage devices, manufacturing tools, etc., can solve the problems of lack of gripper positioning effect, insufficient gripper stability, easy to fall, etc., to increase convenience, save space, The effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

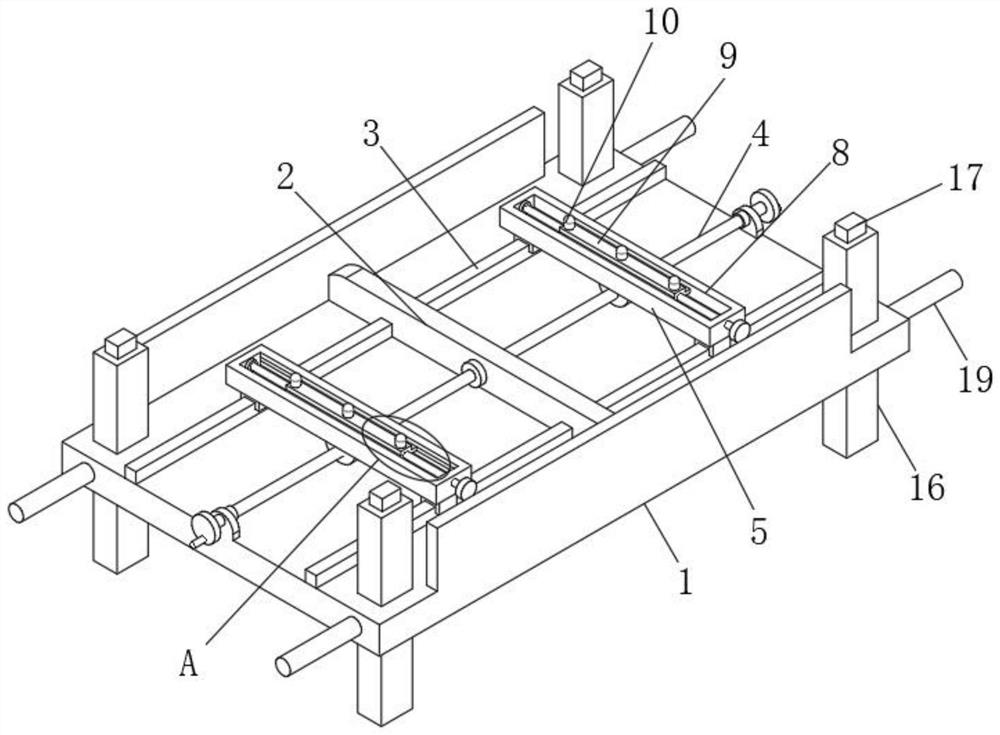

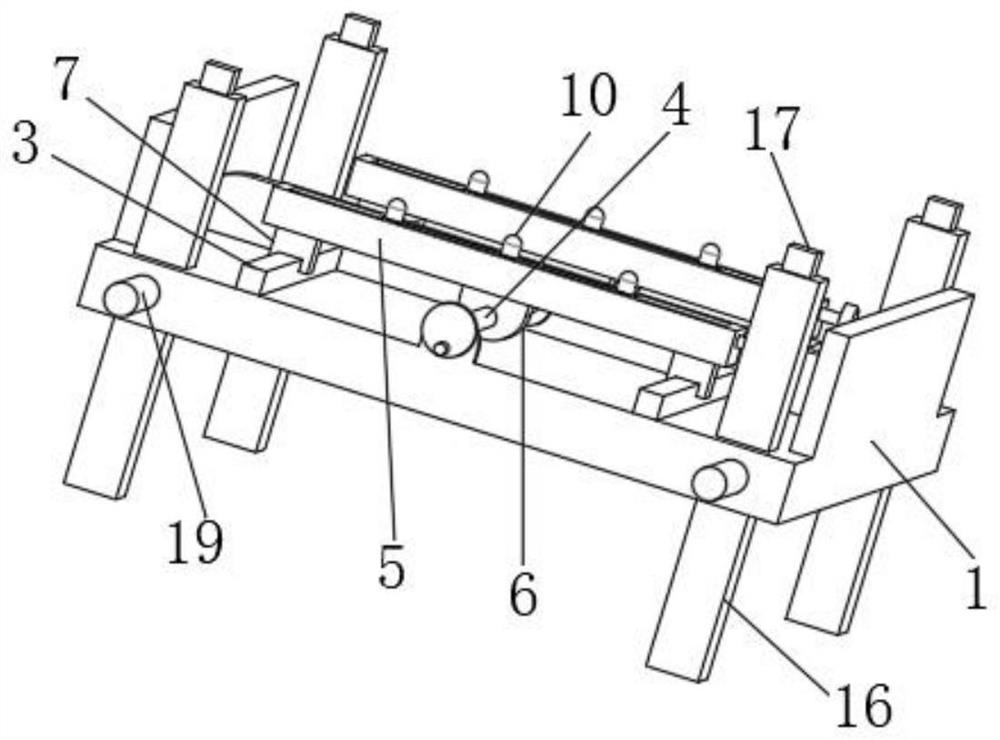

[0037] Such as Figure 1-5 As shown, the embodiment of the present invention provides an industrial robot gripper storage device, which includes a device main body 1 and a support member 5. The upper surface of the device main body 1 and a position near the center are fixedly connected with a fixed partition 2 for the first screw 4, the two side walls of the fixed partition 2 are rotatably connected with the first screw 4 through bearings, which are used to drive the support 5 to move, so as to realize the adjustment effect on the left and right positions of the positioning pin 10, and the upper surface of the device main body 1 and Both sides of the fixed side plate 2 are provided with guide rails 3, the guide rails 3 cooperate with the slider 7, the bottom of the support member 5 is fixedly connected with a fixed block 6, and the fixed block 6 is sleeved on the bottom of the first screw rod 4. surface, and is threadedly connected with the first screw rod 4, the thread force ...

Embodiment 2

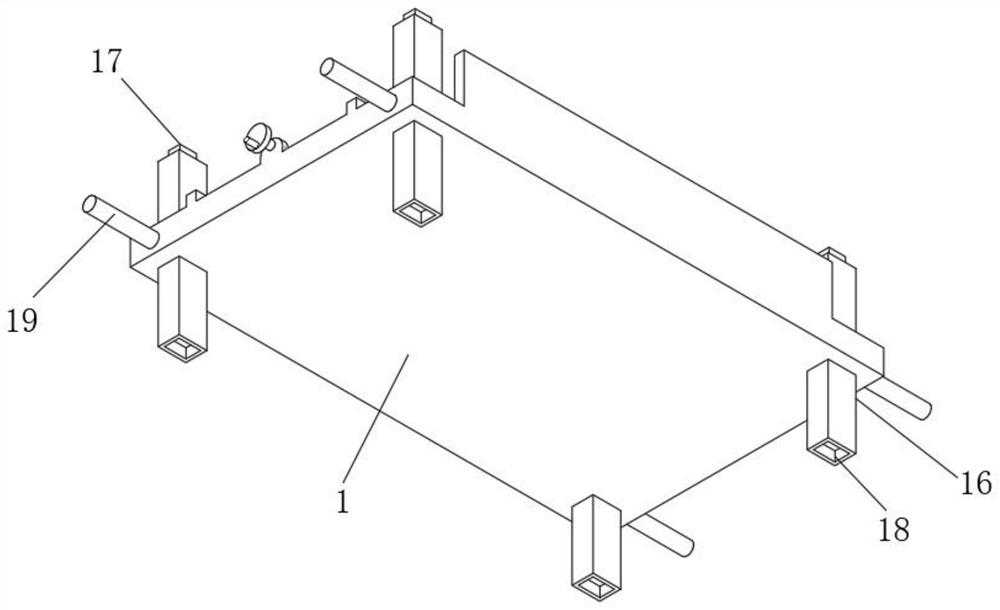

[0040] The bottom of the positioning pin 10 is provided with a slotted hole structure extending inwardly, and a telescopic spring 15 is fixedly connected inside the slotted hole structure. Structural design, when the positioning surface area of the gripper is relatively large, when the pin hole on the gripper cooperates with one of the positioning pins 10, the positioning pin 10 next to it can be compressed by its own gravity, so as not to affect the placement of the gripper , when the four corners of the surface of the main body 1 of the device are fixedly connected with fixed columns 16, the whole device can be supported, and at the same time, the purpose of stacking and splicing can be realized. Block 17, the bottom of the fixed column 16 offers a limit groove 18, and the limit groove 18 cooperates with the limit block 17. When the device main body 1 is stacked and used, the cooperation of the limit groove 18 and the limit block 17 can increase The stability of device sta...

Embodiment 3

[0042] A method for using an industrial robot gripper storage device, characterized in that it includes the following specific steps:

[0043] S1. Adjust the position of the support member 5 according to the positions of the pin holes set on different types of grippers. When adjusting, the first screw rod 4 is rotated, and then the first screw rod 4 is threaded with the fixed block 6 to make the support member 5 Move along the guide rail 3 until the distance of the positioning pin 10 is the same as that of the pin hole on the gripper;

[0044] S2. Match one of the pin holes on the gripper with the positioning pin 10 on one side, and then observe the position of the positioning pin 10 on the other side and the other pin hole on the gripper. If there is an error, turn the second screw rod 13 , the second screw rod 13 is threadedly connected with the adjusting plate 9, so that the adjusting plate 9 slides inside the groove 8 until one of the positioning pins 10 provided on the ad...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap