Steel die grabbing mechanism

A technology of grasping mechanism and steel mold, applied in the direction of manipulator, program-controlled manipulator, chuck, etc., can solve the problem of inconvenient adjustment of the position of the steel mold, and achieve the effect of large bearing capacity and precise installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

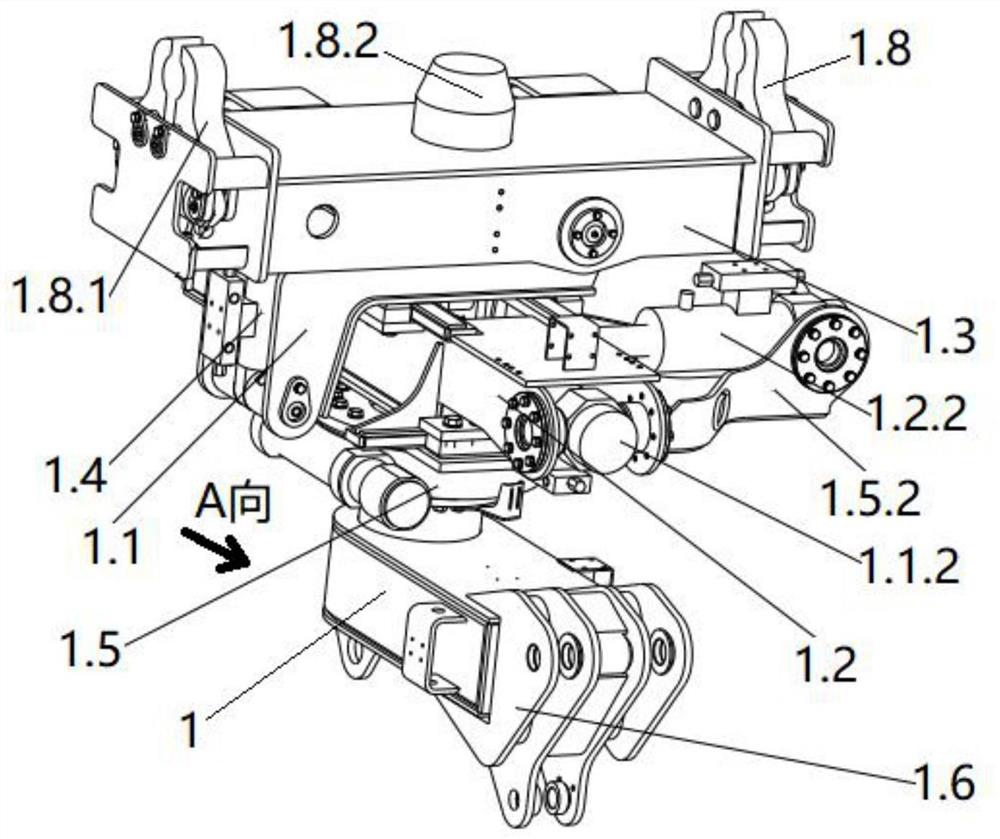

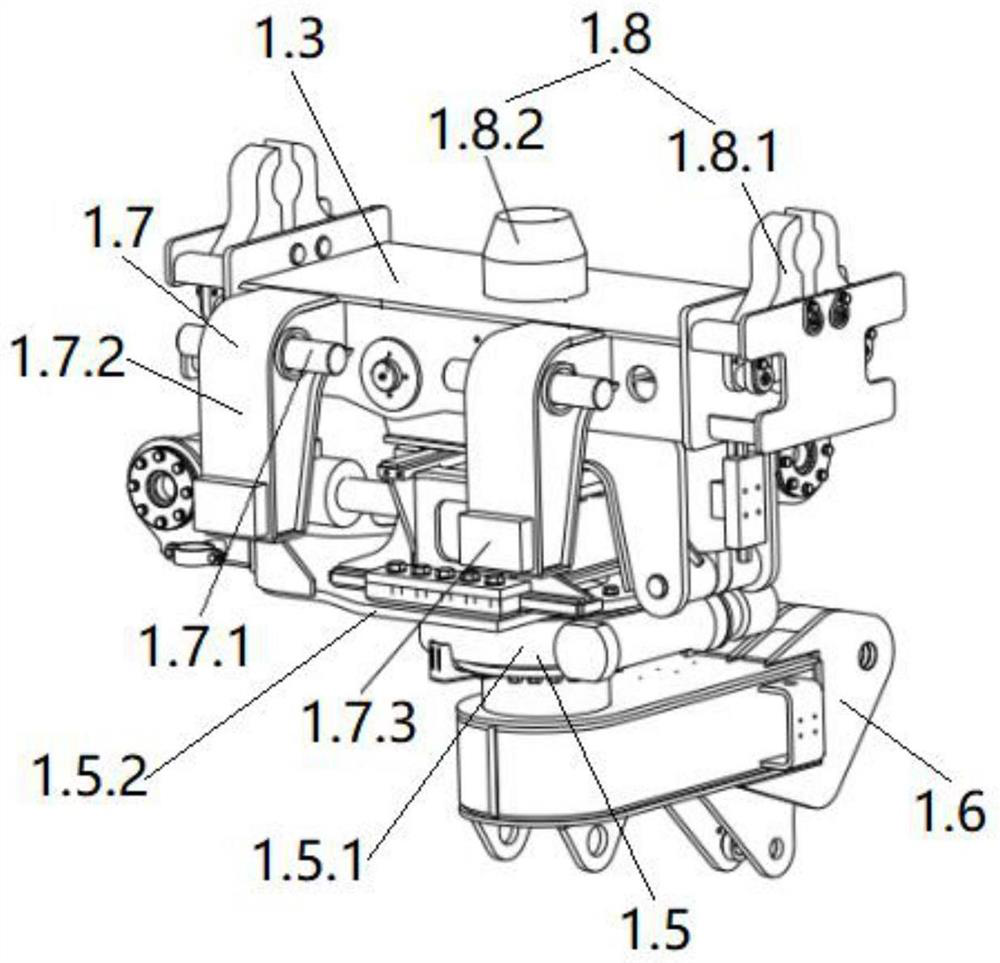

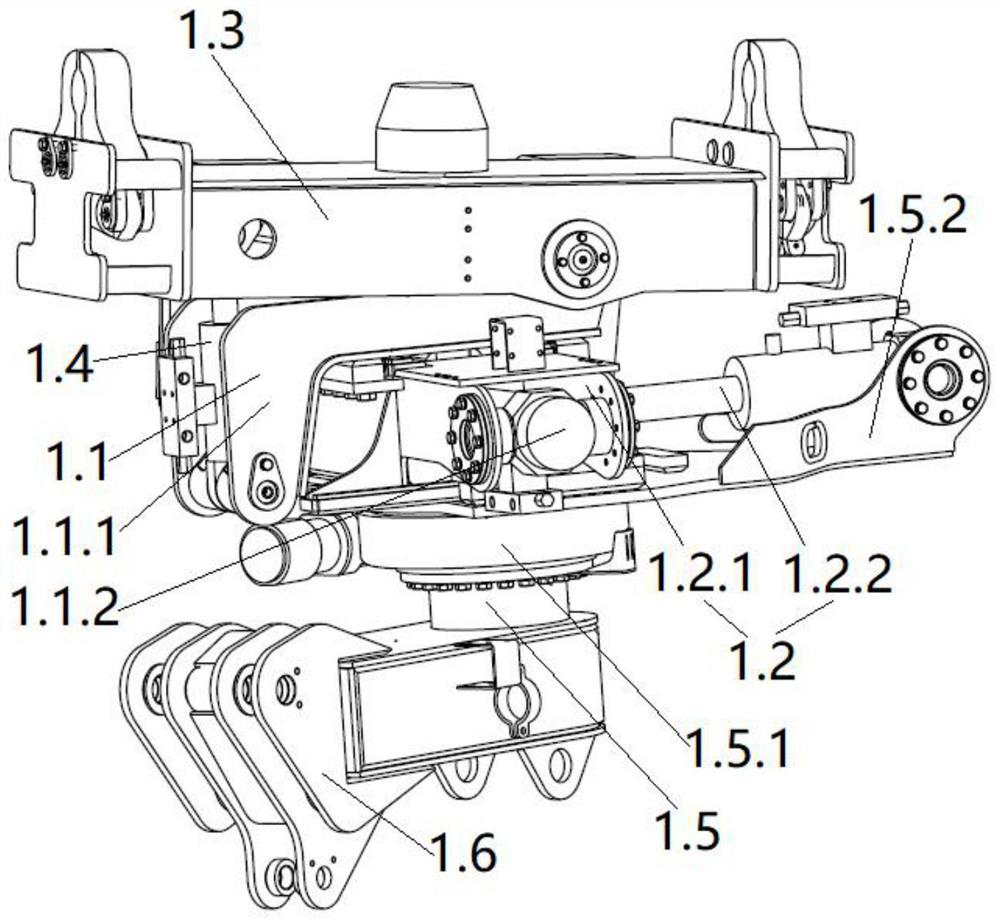

[0038] see Figure 1 to Figure 9 , a steel mold grasping mechanism, this embodiment is applied to the grasping and installation of the prefabricated steel structure (ie steel mold) inside the tunnel.

[0039] A steel mold grasping mechanism, including a detachably connected mechanical gripper 1 and a steel mold connection tool; the mechanical gripper 1 includes a first sliding mechanism 1.1, a second sliding mechanism 1.2 and a The connecting frame 1.3 of the steel mold connecting tool; the connecting frame 1.3 is set on the first sliding mechanism 1.1, the first sliding mechanism 1.1 is set on the second sliding mechanism 1.2, and the second A sliding mechanism 1.1 is perpendicular to the sliding direction of the second sliding mechanism 1.2, and is used to realize the sliding of the connecting frame 1.3 in the front, rear and left and right directions, so as to facilitate the adjustment of the installation position of the steel mold inside the tunnel; the mechanical gripper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com