Manufacturing equipment and method of polystyrene foam plate beam

A technology for polystyrene foam and manufacturing equipment, which is applied to manufacturing equipment and manufacturing fields of polystyrene foam slab beams, can solve problems such as excessive power, increased cost, motor consumption, etc., and achieves energy and cost saving, noise reduction, The effect of saving resources and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

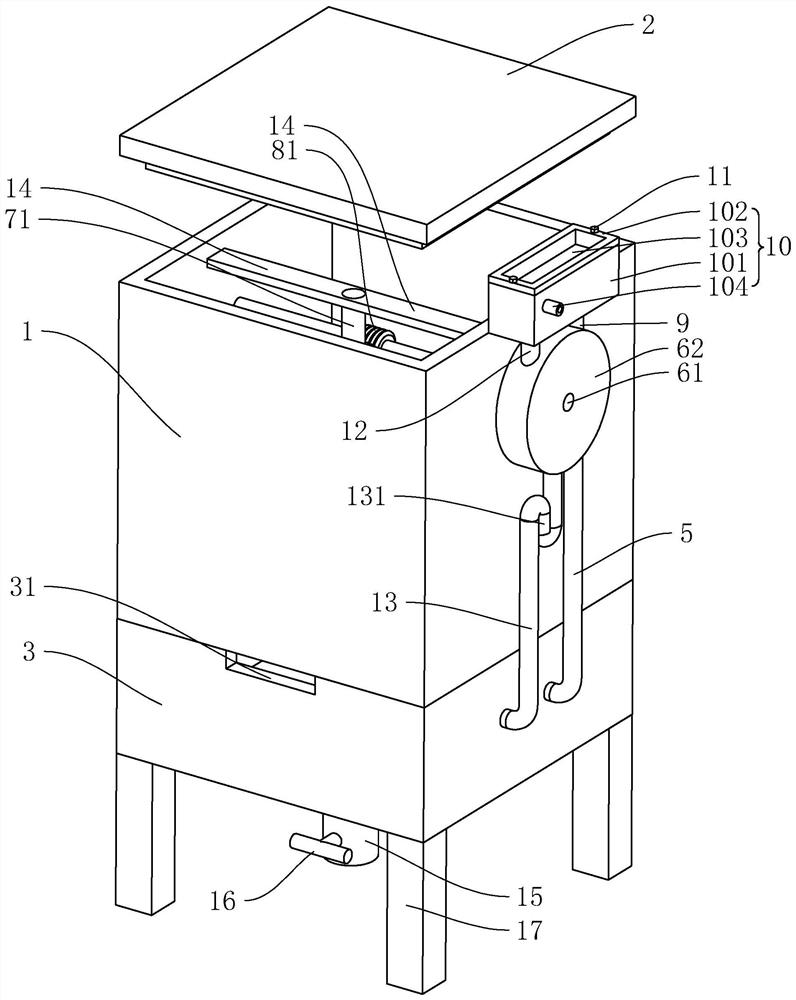

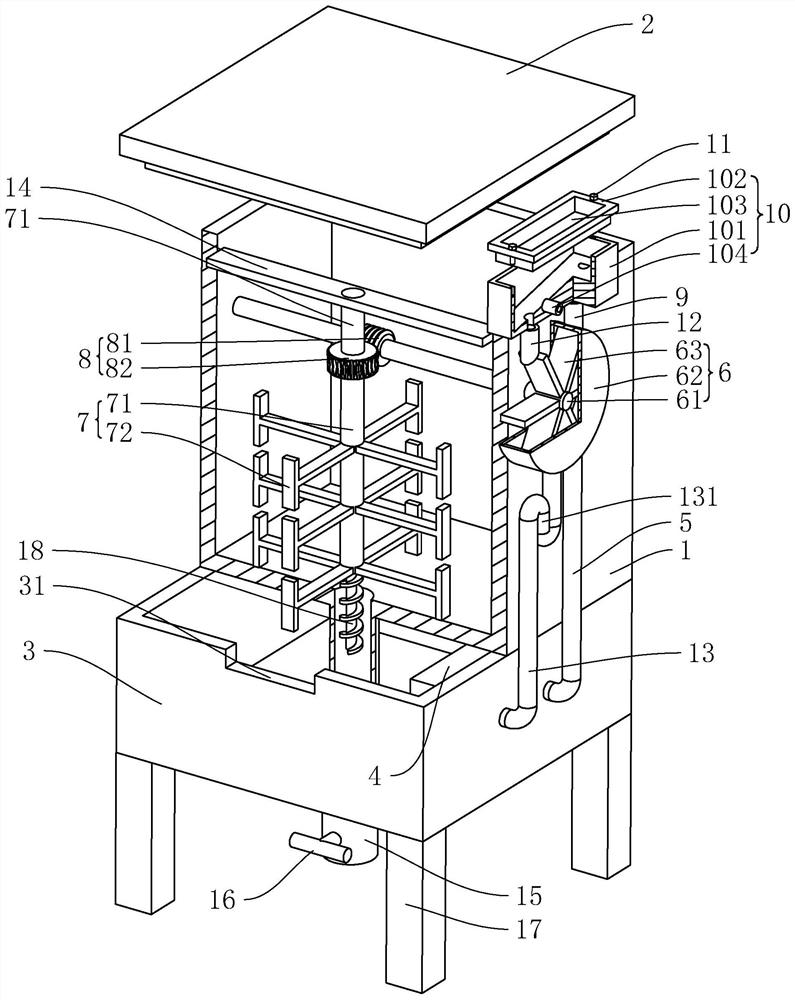

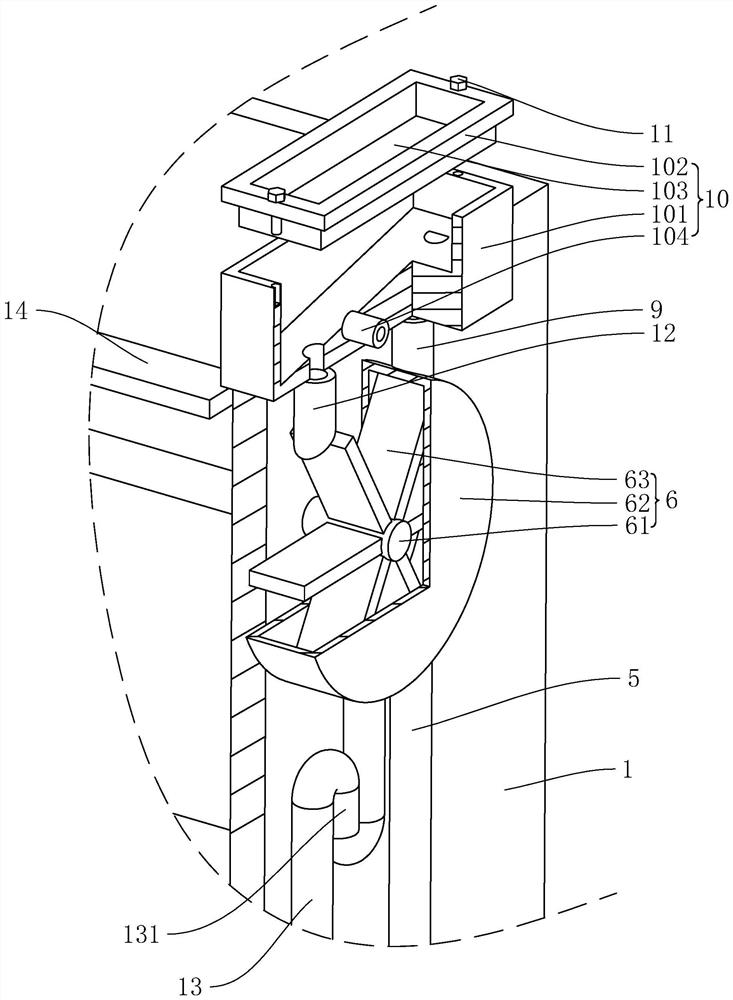

[0043] refer to figure 1 and figure 2, including a melting furnace 1, and a furnace cover 2 is fastened above the melting furnace 1. A heating chamber 3 is arranged at the bottom of the melting furnace 1 , and a water tank 4 is arranged in the heating chamber 3 , and a first steam pipe 5 is connected to the water tank 4 . The first steam pipe 5 extends to the outside of the heating chamber 3 and is connected with a power assembly 6 . A stirring assembly 7 is arranged in the furnace 1 , and a transmission assembly 8 connected with the power assembly 6 is arranged on the stirring assembly 7 . Coal is filled in the heating chamber 3 and ignited, the coal burns to heat the furnace 1, the coal heats the water tank 4, the water in the water tank 4 evaporates into steam, and the steam enters the first steam pipe 5, and the power assembly 6 converts the first steam pipe 5 The steam in the furnace is converted into mechanical energy, and the mechanical energy is transmitted to the s...

Embodiment 2

[0063] refer to Figure 4 , a kind of manufacturing method of polystyrene foam board girder, comprises the following steps:

[0064] S100. Open the cover plate 102 and inject water into the cooling box 101;

[0065] S200. Fasten the cover plate 102, use the fixing bolt 11 to pass through and thread-connect the cooling box 101, and fix the cover plate 102 and the cooling box 101;

[0066] S300. Put coal in the heating chamber 3 through the ventilation groove 31;

[0067] S301. Light the coal in the heating chamber 3 through the ventilation slot 31;

[0068] S400. Pour polystyrene resin and polymer into the melting furnace 1;

[0069] S500. After the material in the furnace 1 reaches the standard, place the mold under the discharge pipe 15, and open the valve 16; close the valve 16 after the mold is full.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com