A shaft hole coaxiality positioning assembly and a positioning method using the same

A technology for positioning components and positioning methods, applied in aircraft assembly and other directions, can solve the problems of accelerated wear, uneven force on rollers, and long time consumption, and achieve the effects of reducing production complexity, increasing service life, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

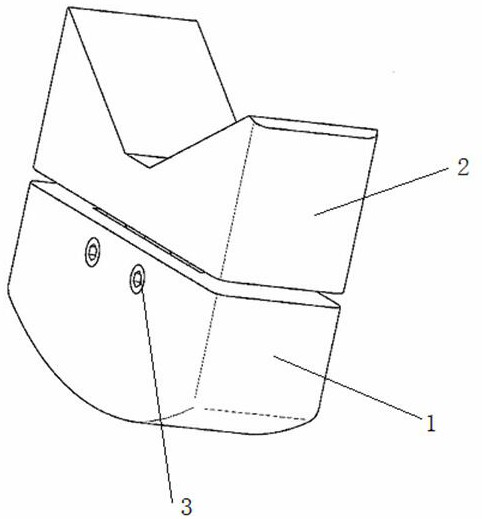

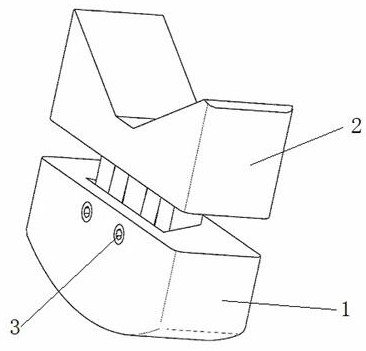

[0047] A shaft hole coaxiality positioning assembly belongs to the technical field of shaft hole installation in aircraft manufacturing. figure 1 , including a hole contact block 1 and a shaft contact block 2, one end of the hole contact block 1 is an arc structure 1.1; the other end of the hole contact block 1 is provided with a groove 1.2, and the side of the hole contact block 1 is provided with a fixing hole 1.3, so The arc surface structure 1.1 of the hole contact block 1 is used to contact the inner surface of the hole, one end of the shaft contact block 2 is an angular positioning groove 2.1; the other end of the shaft contact block 2 is provided with a convex structure 2.2 matching the groove 1.2 , the angular positioning groove 2.1 is used to contact the outer surface of the shaft, the raised structure 2.2 of the shaft contact block 2 can slide in the groove 1.2, and pass through the fixing hole 1.3 through the top wire 3 to the hole contact block 1 and The shaft cont...

Embodiment 2

[0053] This embodiment is a further optimization of Embodiment 1. A shaft hole coaxiality positioning assembly belongs to the technical field of shaft hole installation in aircraft manufacturing, and includes a hole contact block 1 and a shaft contact block 2. The hole contact block 1 One end is an arc structure 1.1; the other end of the hole contact block 1 is provided with a groove 1.2, the side of the hole contact block 1 is provided with a fixing hole 1.3, and the arc structure 1.1 of the hole contact block 1 is used to contact the inner surface of the hole, One end of the shaft contact block 2 is an angular positioning groove 2.1; the other end of the shaft contact block 2 is provided with a raised structure 2.2 matching the groove 1.2, and the angular positioning groove 2.1 is used to contact the outer surface of the shaft. The protruding structure 2.2 of the contact block 2 can slide in the groove 1.2, and the hole contact block 1 and the shaft contact block 2 are fixed ...

Embodiment 3

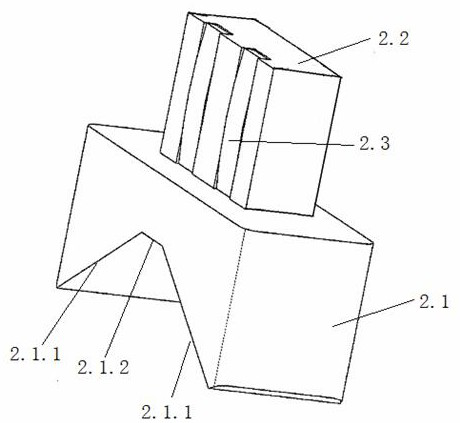

[0056] Compared with the embodiment 1-2, the difference between this embodiment is that the convex structure 2.2 of the shaft contact block 2 is a trapezoidal protrusion 2.2.1 matched with the trapezoidal groove 1.2.1, refer to Figure 4 , the angular positioning groove 2.1 and the trapezoidal protrusion 2.2.1 on the shaft contact block 2 are both axisymmetric structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com