Comprehensive concealed excavation cable tunnel maintenance communicating vertical shaft

A cable tunnel and comprehensive technology, which is applied in mine/tunnel ventilation, shaft equipment, mining equipment, etc. It can solve problems such as fire rescue, post-disaster repair difficulties, personal casualties, pipelines that cannot be released or drawn out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

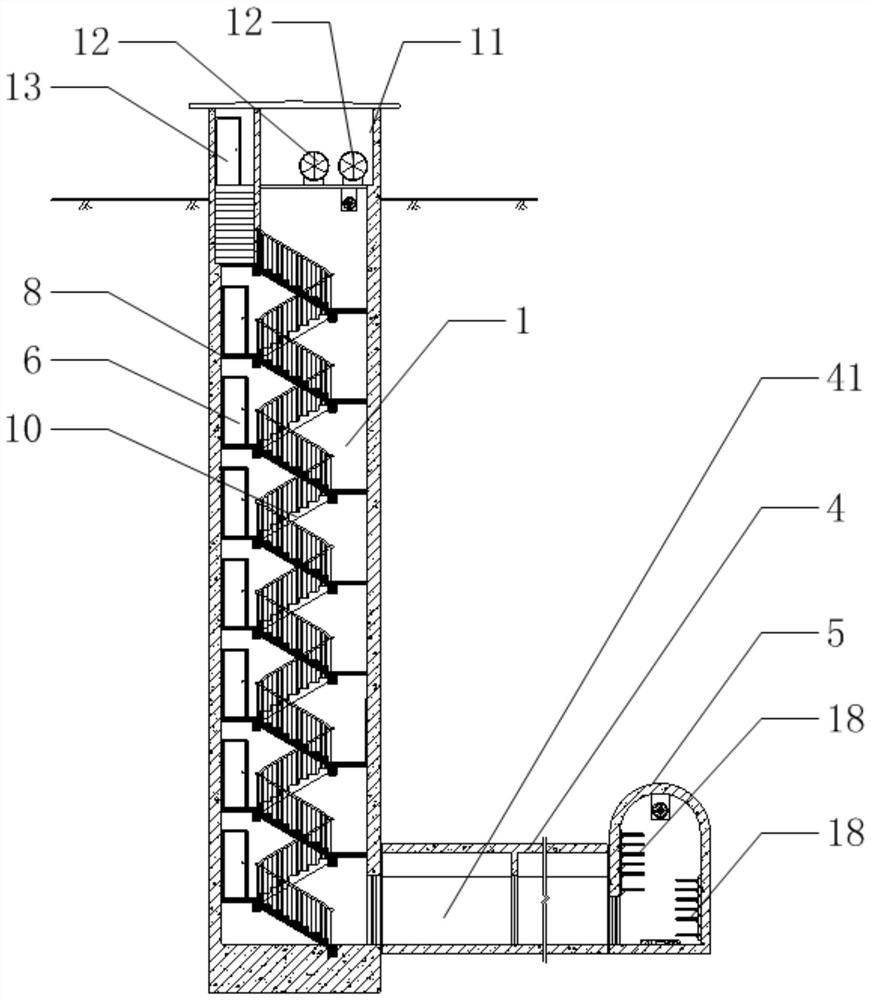

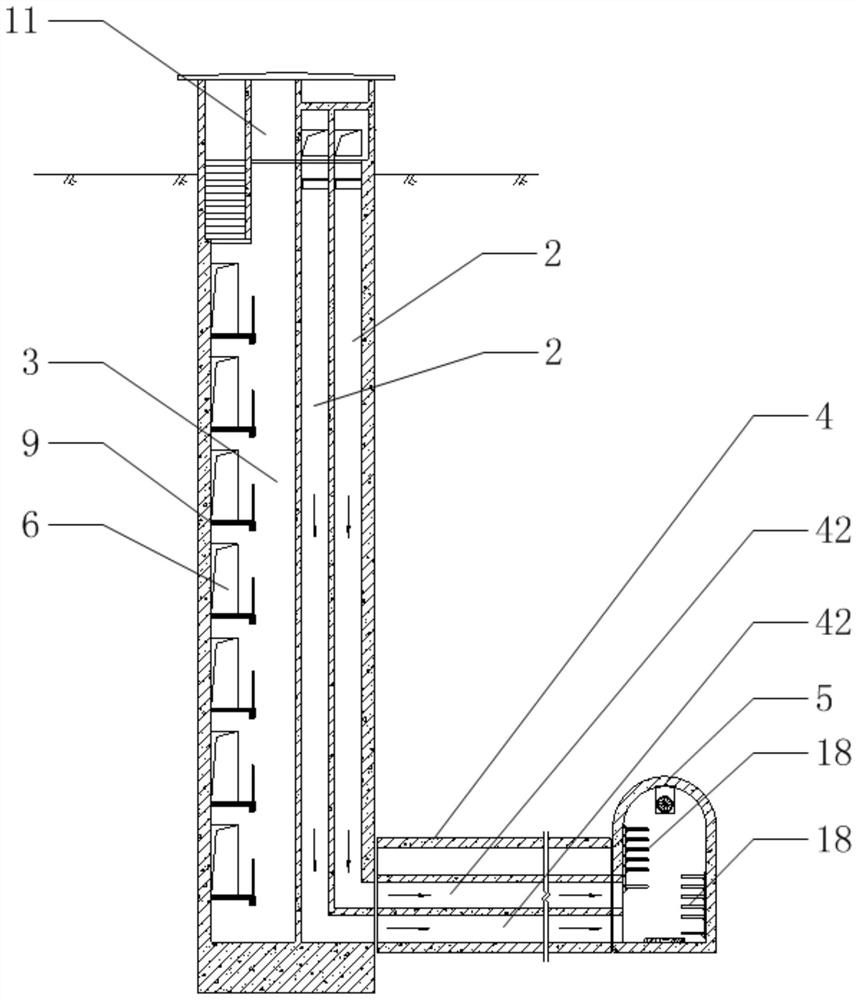

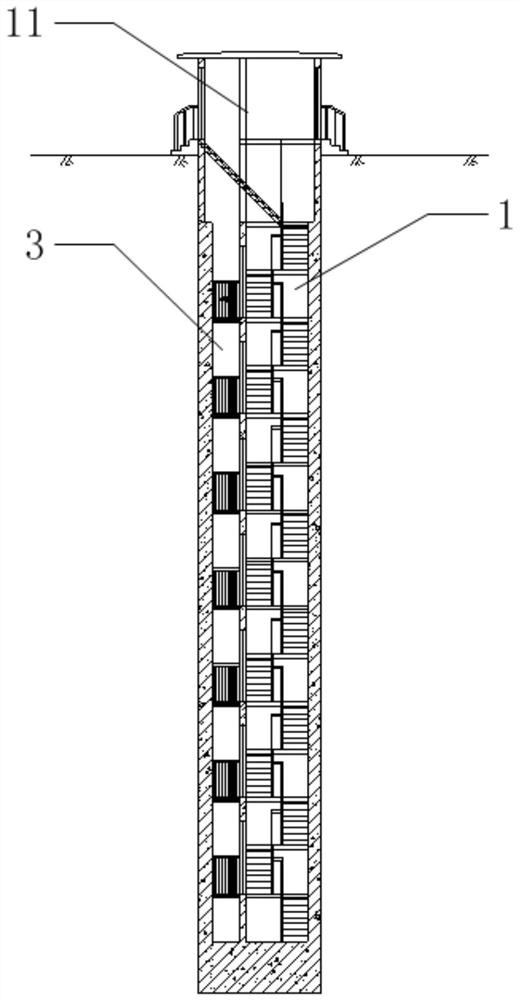

[0026] The core of the present invention is to provide a comprehensive underground excavation cable tunnel maintenance connecting shaft, which isolates the air supply channel and the maintenance channel, and the functional spaces are independent and do not interfere with each other. The maintenance channel forms an independent smoke-proof stairwell, which can greatly reduce The smoke and heat entering the maintenance passage ensure the survival time and possibility of personnel taking refuge in the stairwell.

[0027] In order to enable those skilled in the art to better understand the scheme of the present invention, the following combination Figure 1 to Figure 8 The present invention will be further described in detail with specific embodiments.

[0028] The specific embodiment of the present invention provides a comprehensive underground excavation cable tunnel maintenance connecting shaft, including maintenance channel 1, air supply channel 2 and feeding channel 3, each c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com