Metal joint bearing damping and noise reduction method and metal joint bearing

A joint bearing and metal technology, applied in the field of rail vehicles, can solve the problems of fast wear, short life, high noise, etc., and achieve the effects of reducing fit clearance, prolonging service life, reducing impact force and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below by specific embodiment and in conjunction with accompanying drawing, the present invention will be further described:

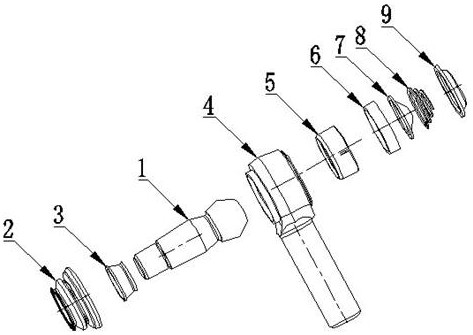

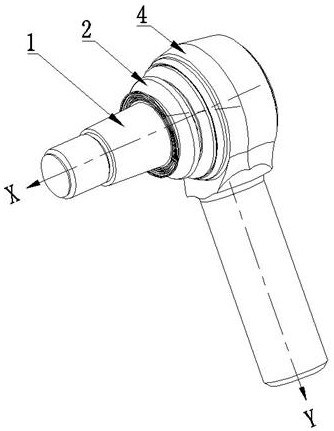

[0054] Such as Figures 1 to 5 As shown: the metal joint bearing includes: mandrel 1, dust cover 2, dustproof lining 3, housing 4, outer ring 5, retaining ring 6, ball bowl 7, spring 8 and end cover 9.

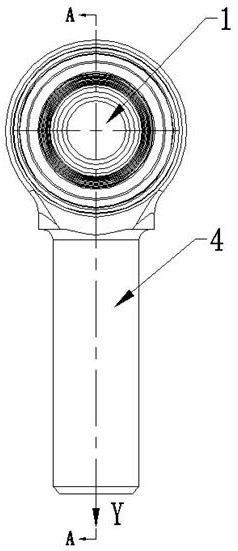

[0055] Housing 4 as Figures 6 to 9 As shown: the housing 4 is cylindrical, and a cylindrical housing shaft hole 41 is provided at one end, and a step for installing the outer ring 5 and the retaining ring 6 is provided in the housing shaft hole 41 . The step height H1 of the retaining ring is smaller than the height H2 of the retaining ring, so that the end cover 9 can press the outer ring 5 through the retaining ring 6 to prevent the outer ring 5 from moving in the shaft hole 41 of the housing. One end of the shaft hole 41 of the housing has a large opening, and the wall thickness of the end is relatively thin. After the outer ring 5, the ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com