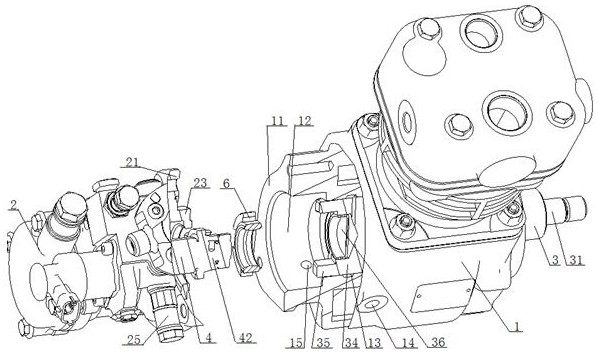

Transmission connection structure of air compressor and high-pressure oil pump

A high-pressure oil pump and transmission connection technology, which is applied in the direction of machines/engines, pumps, piston pumps, etc., can solve the problem of large space for air compressors and high-pressure oil pumps, and achieve ingenious lubricating structure design, high connection strength, and off-center rotation The effect of small displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

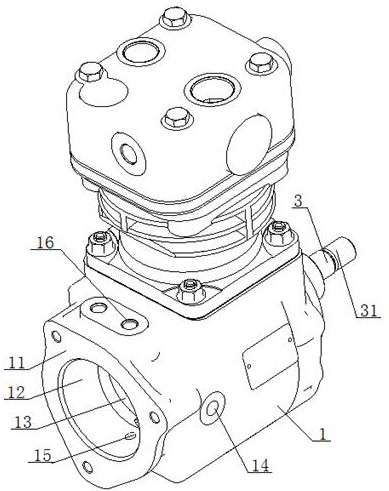

[0049]A transmission connection structure of an air compressor and a high-pressure oil pump. The transmission system includes: an air compressor 1 and a high-pressure oil pump 2. The air compressor 1 is provided with an air compressor crankshaft 3, and the high-pressure oil pump 2 is provided with A high-pressure oil pump crankshaft 4, the power input end of the air compressor crankshaft 3 is fixedly connected with a transmission gear 5, and the power output end of the air compressor crankshaft 3 is in drive cooperation with the power input end of the high-pressure oil pump crankshaft 4; The crankshaft 3 includes an integrated power input shaft 31, a rotating shaft 32, a crank connecting rod assembly 33, and a power output shaft 34. The end of the power input shaft 31 is fixedly connected to one end of the crank connecting rod assembly 33 through the rotating shaft 32 , The other end of the crank connecting rod assembly 33 is fixedly connected to one end of the power output shaft 34...

Embodiment 2

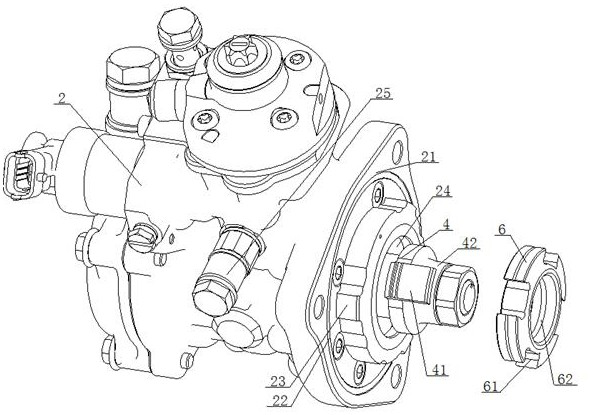

[0051]Embodiment 2 is basically the same as embodiment 1, and the difference lies in:

[0052]The air compressor coupling key teeth 35 and the high pressure oil pump coupling key teeth 41 have the same cross-sectional shape, and the heights of the air compressor coupling key teeth 35 and the high pressure oil pump coupling key teeth 41 are greater than or equal to the coupling 6 The thickness of the air compressor coupling key teeth 35, the high-pressure oil pump coupling key teeth 41 and the coupling 6 assembling the combined part is a complete ring; the middle of the oil pump end flange 21 is provided An annular boss 23. A pump shaft fixing hole 24 is opened in the middle of the ring boss 23. The pump shaft fixing hole 24 rotates with the crankshaft 4 of the high pressure oil pump through a bearing. The outer edge of the ring boss 23 is connected to the coupling shaft. The lubrication groove 12 is inserted and fitted; the air compressor 1 housing is provided with an air compressor lu...

Embodiment 3

[0054]Embodiment 3 is basically the same as embodiment 2, and the difference lies in:

[0055]The width of the key tooth groove 61 is greater than or equal to 6 mm, the groove depth of the key tooth groove 61 is greater than or equal to 5 mm, the diameter of the shaft hole 62 is greater than or equal to 30 mm, and the groove depth of the key tooth groove 61 is consistent with that of the coupling The ratio of the circumferential thickness of the device 6 is less than or equal to 0.75; the transmission gear 5 is sleeved on the power input shaft 31, and the transmission gear 5 is connected to the rotating shaft 32 through a positioning pin 51.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com