Multi-station high-precision inductor automatic assembling machine

An automatic assembly machine, high-precision technology, applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve problems such as low production efficiency, inductor offset, dispensing errors, etc., to improve product yield , Improve production efficiency, reduce the effect of rework rate and scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate those skilled in the art to understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

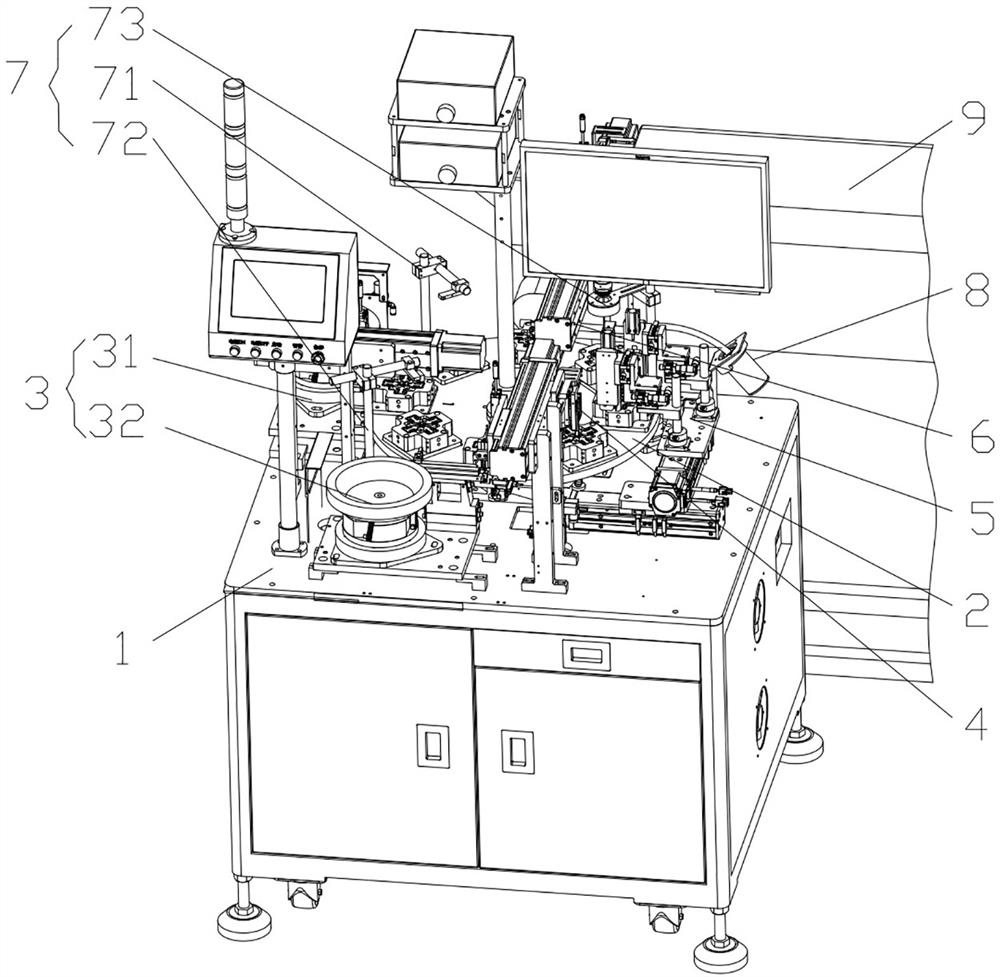

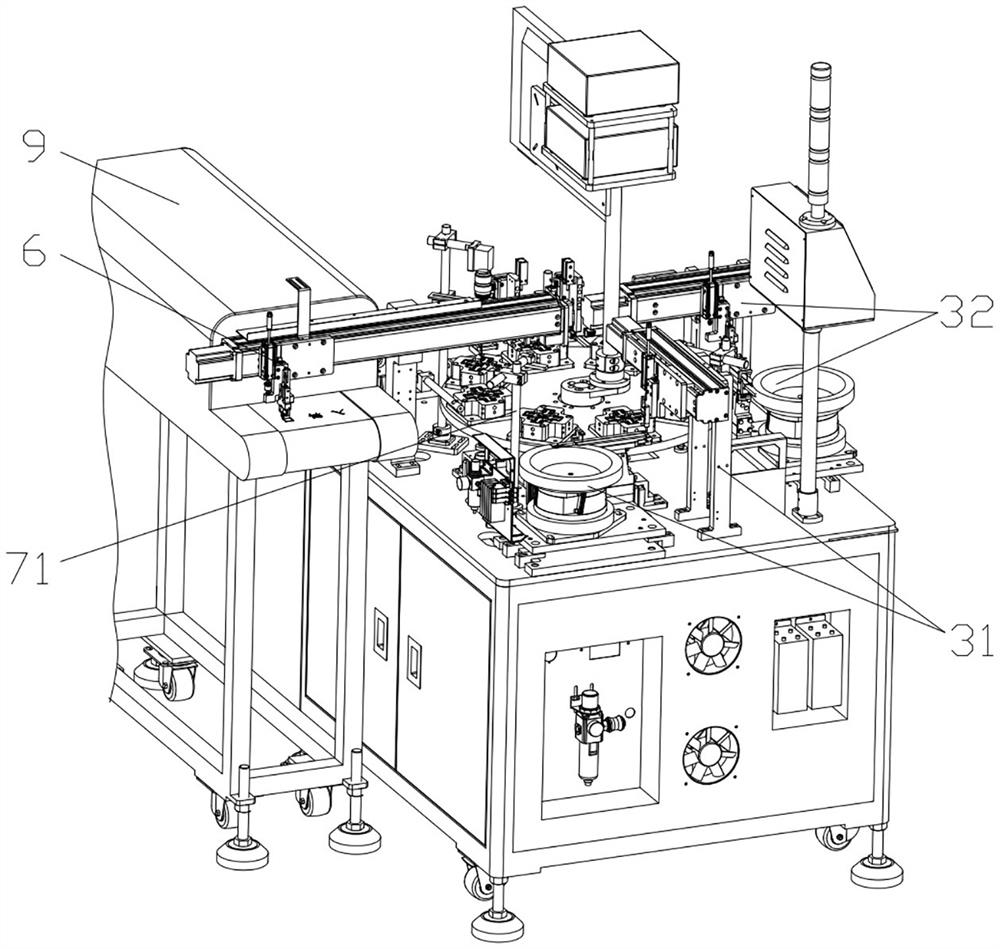

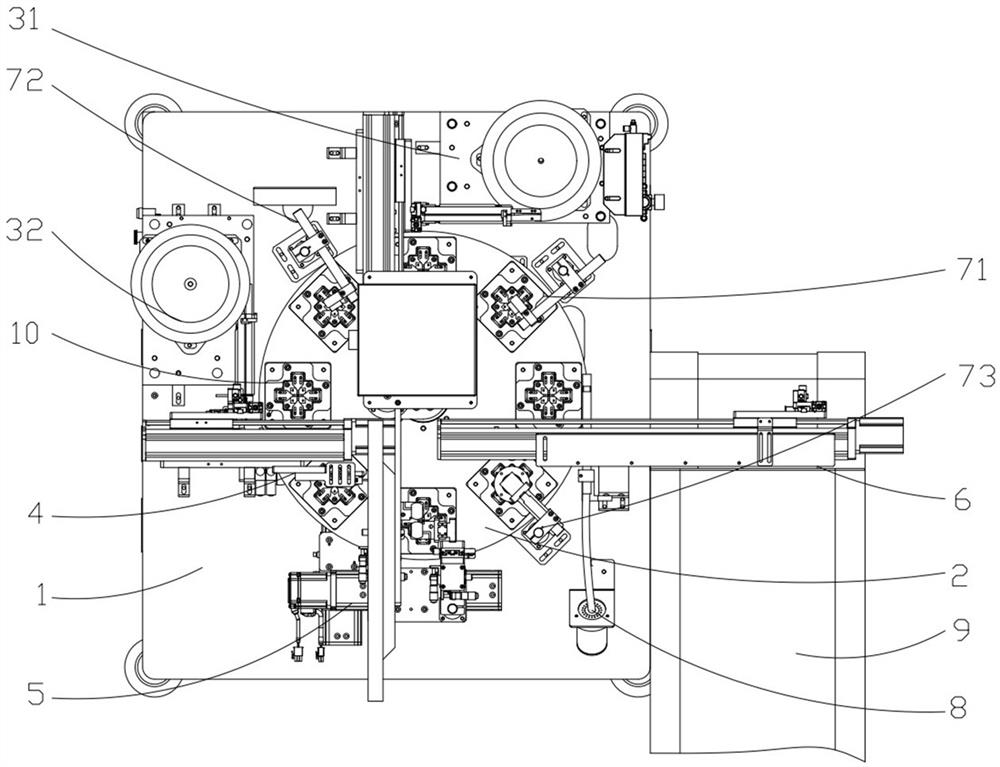

[0035] refer to Figure 1 to Figure 14 , The invention provides a multi-station high-precision inductance automatic assembly machine. The multi-station high-precision inductance automatic assembly machine includes a machine platform 1, a rotating mechanism 2 arranged on the machine platform 1, a feeding device 3 arranged around the rotating mechanism 2, a pressing mechanism 4, a dispensing mechanism 5, and a discharging mechanism 6. One side of the discharge mechanism 6 is provided with a conveying device 9 . Such as Figure 4 As shown, the rotating mechanism 2 includes an indexing turntable 21 arranged on the machine 1 , and a divider 22 for driving the indexing turntable 21 , and the divider 22 can be driven by a motor. A plurality of positioning jig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap