Storage battery module

A battery module and battery technology, applied in the direction of lithium batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problems of abnormal battery change, melting, overheating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

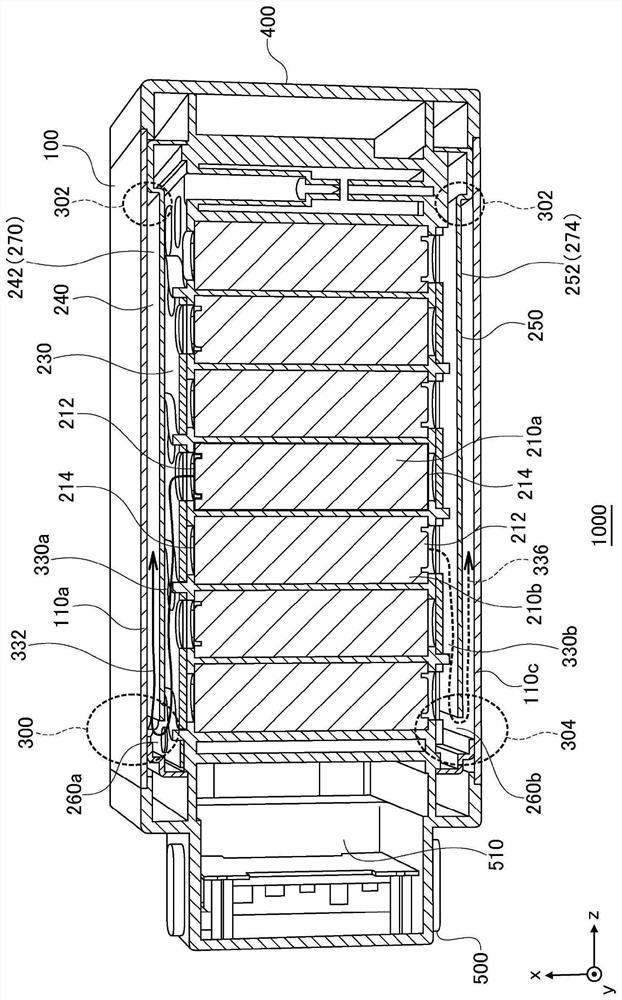

[0022] Before concretely describing the embodiments of the present disclosure, the outline of Embodiment 1 will be described. This embodiment relates to a battery module that accommodates a plurality of battery cells. When each battery cell is a lithium ion secondary battery, gas is generated in the battery cell when an internal short circuit or the like occurs. Also, the pressure inside the battery cell increases due to gas generation, but the gas is released from the positive electrode side to the outside of the battery cell through the safety mechanism. Such gas has high temperature and high pressure, and if combustion by the gas occurs, other battery cells in the battery module will also run away thermally (burning spread). Due to this burning, the entire battery module or the entire product may burn. In order to suppress the spread of combustion by gas, for example, it is effective to provide an exhaust port in the battery module and to release the gas from the exhaust ...

Embodiment 2

[0052] Next, Example 2 will be described. Example 2, like Example 1, relates to a battery module that accommodates a plurality of battery cells. In Example 1, the first exhaust path and the second exhaust path are formed using different surfaces of the inner case. On the other hand, the second embodiment arranges the middle case between the outer case and the inner case, the space between the inner case and the middle case forms the first exhaust path, and the space between the middle case and the outer case The space between forms the second exhaust path. Hereinafter, the difference from Example 1 will be mainly explained.

[0053] Figure 6 (a)-(b) are perspective views showing the structure of the battery module 2000 . Figure 6 (a) is a perspective view showing the appearance of the battery module 2000, Figure 6 (b) is the perspective view which looked at the battery module 2000 from the lower side. The battery module 2000 includes an outer case 2100 and a lower cas...

Embodiment 3

[0068] Next, Example 3 will be described. The third embodiment relates to a battery module that accommodates a plurality of battery cells in the same manner as described above. In Examples 1 and 2, a metal outer case is disposed on the outermost side of the battery module. In Example 3, a resin cover is arranged on the outside of the outer case for the purpose of increasing the degree of freedom of the mounting structure of the battery module charger or load device and increasing the designability of the battery module. Hereinafter, the difference from Example 1 will be mainly explained.

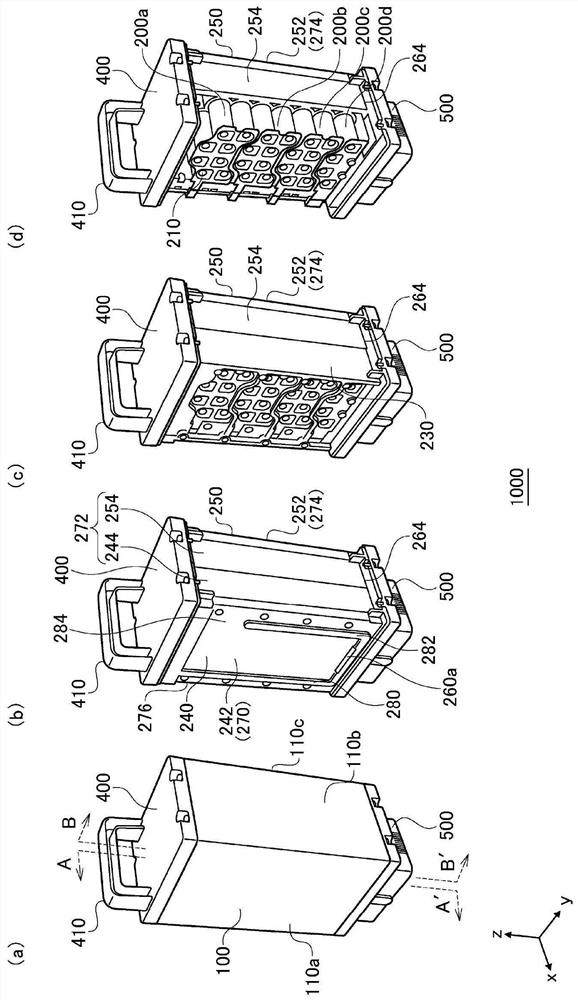

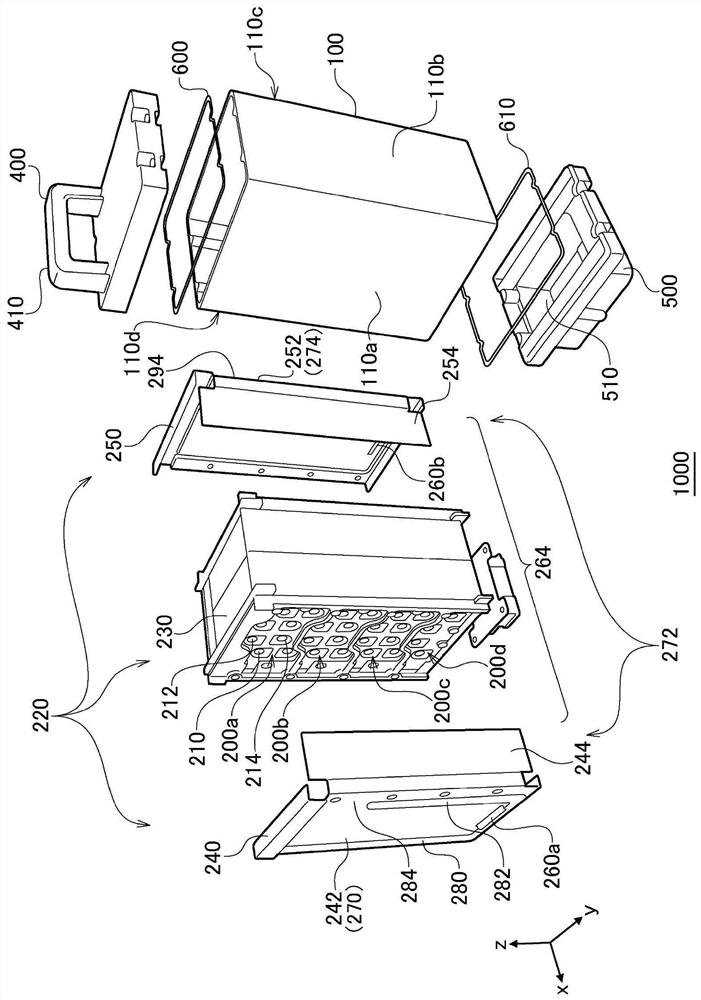

[0069] Figure 9 (a)-(d) are perspective views showing the structure of the battery module 3000 . exist Figure 9 In (a)-(d), the same orthogonal coordinate system as above is specified. Figure 9 (a) shows the appearance of the battery module 3000 . The battery module 3000 includes a resin cover 3700 . The resin cover 3700 is formed of resin, and has a vertically elongated box shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com