Display device and reflction preventing substrate

A display device and anti-reflection technology, which is applied in identification devices, sputtering plating, ion implantation plating, etc., can solve the problem of deterioration of anti-reflection film or anti-reflection film, poor moisture penetration resistance of anti-reflection film The effects of stabilizing film thickness and optical properties, suppressing moisture release, and achieving thin film reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

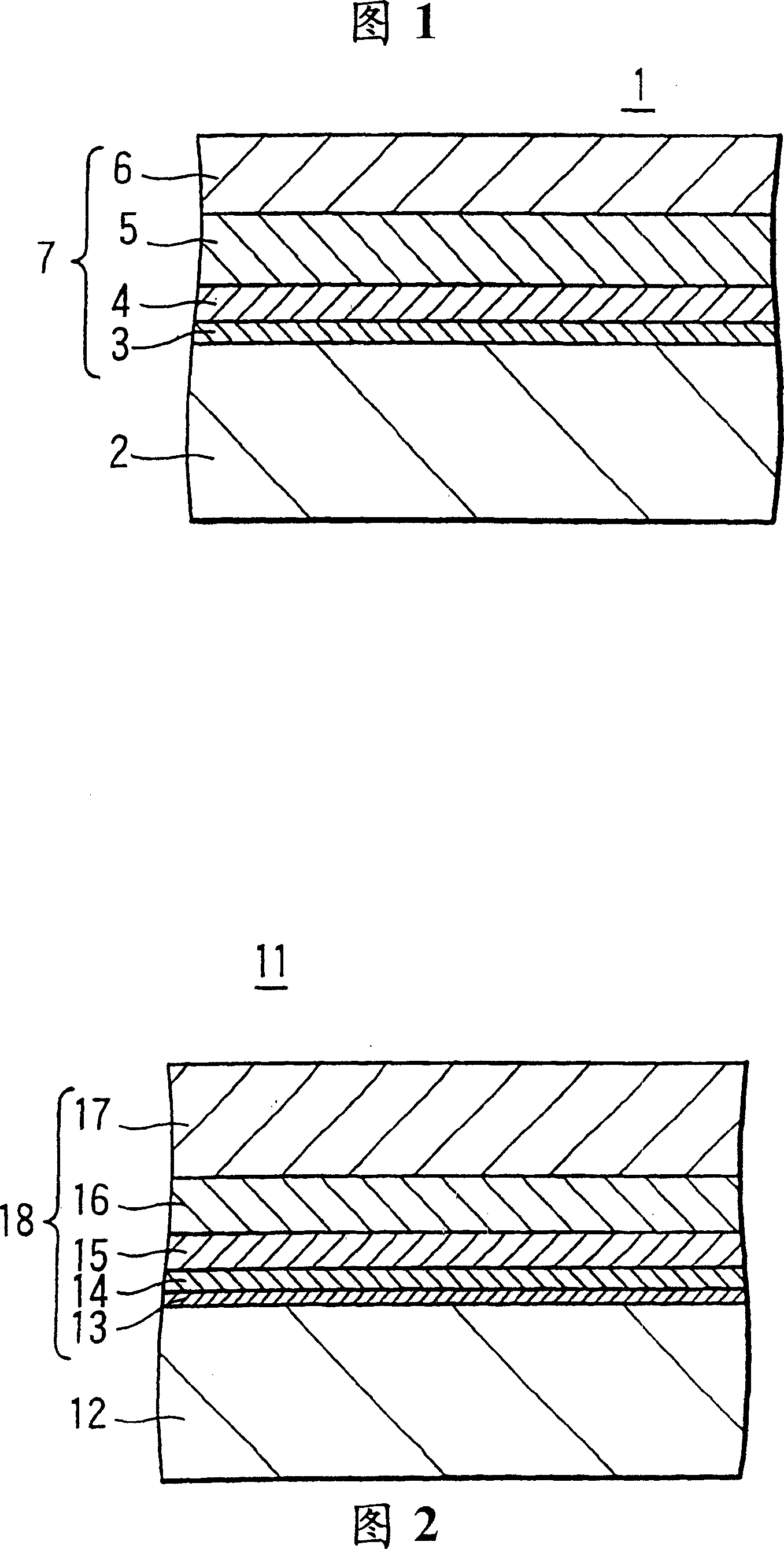

[0076] An example of the preparation method of the anti-reflection film 11 is given. The surface of the transparent substrate 12 in O 2 , Ar, N 2 atmosphere, or selected from O 2 , Ar, N 2 The glow discharge treatment is carried out in one or both of the atmospheres to activate the surface of the lining material 12 . Next, in order to obtain a stronger adhesive force between the substrate 12 and the anti-reflection film 18, the first layer of film 13 is formed of, for example, SiO X membrane. Due to SiO X The film 13 absorbs little light, and as a transparent optical film, it is preferable that the film thickness is 10 nm or less. It is preferable to make the light absorption of the first film 13 as small as possible. The optimum condition range when the first layer film 13 is formed of a single-layer film is preferably a light transmittance region of 86% to 92% that can be realized as a high transmittance.

[0077] The high-refractive-index, high-resistance second fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com