Vacuumizing device for milking dairy cows

A vacuum pumping device, a technology for cows, applied in milking devices, applications, dairy products, etc., can solve problems such as high pumping speed and damage to the udder of cows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

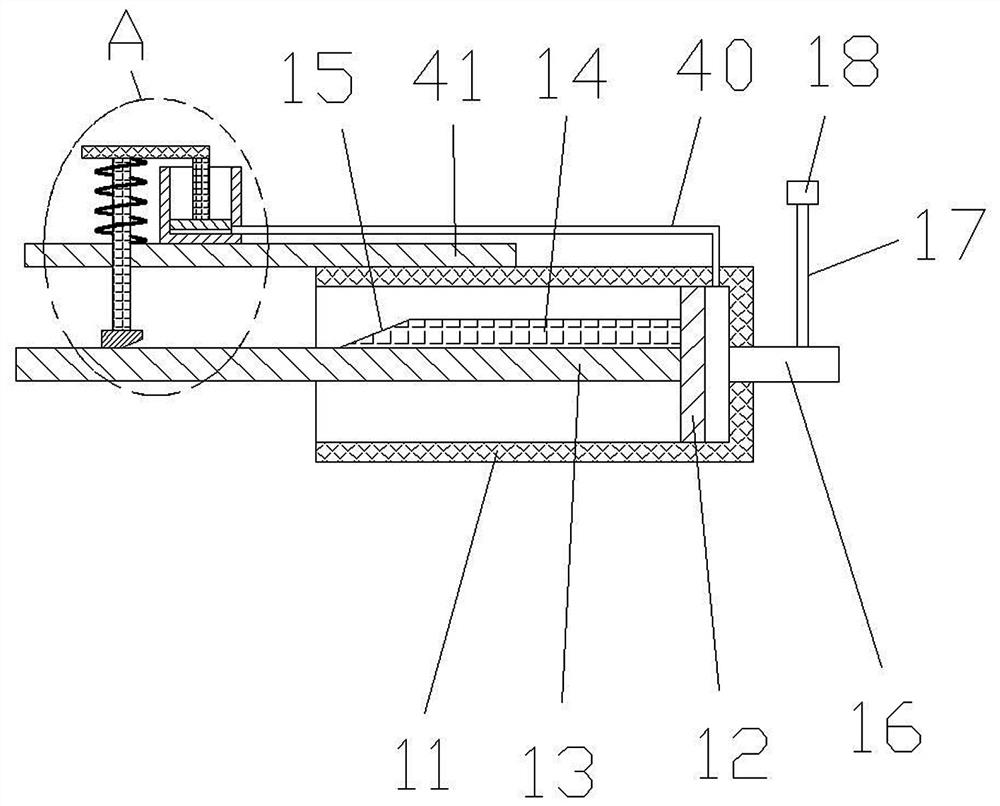

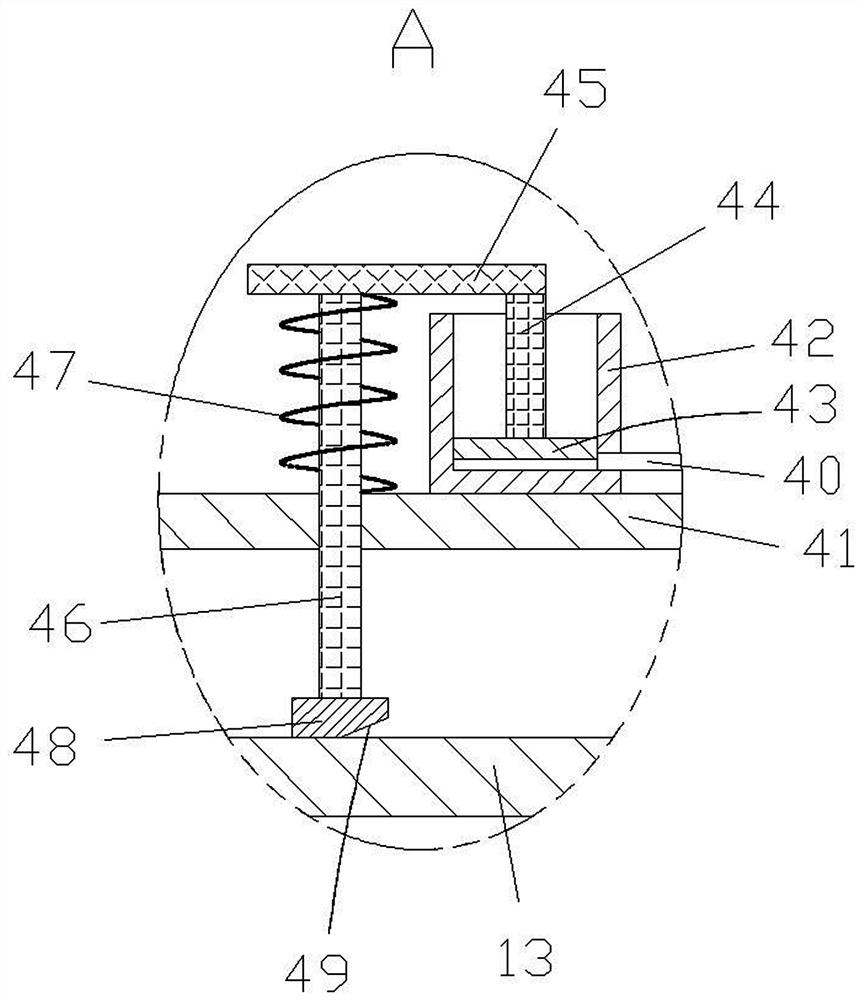

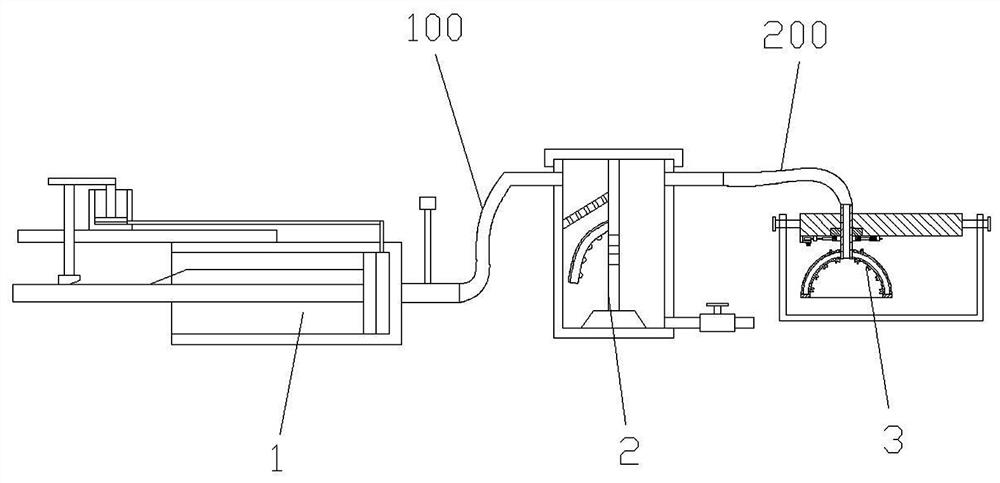

[0021] like Figure 1-2 As shown, the vacuum pumping device 1 provided by the present invention includes a first barrel 11, a first air pipe 16 is arranged at the bottom of the first barrel 11, and a vacuum breaking pipe 17 is arranged on one side of the first air pipe 16, and the vacuum breaking pipe 17 is installed on the top There is a vacuum breaker valve 18. The first barrel 11 is slidably connected to the first piston plate 12 , one side of the first piston plate 12 is fixedly connected to the first piston rod 13 , and a first push-pull for controlling the reciprocating movement of the first piston rod 13 is installed on the outside of the first barrel 11 The first push-pull device adopts the prior art, which will not be repeated here. One side of the first barrel 11 is fixedly connected to the fixing plate 41 , one side of the fixing plate 41 is fixedly connected to the second barrel 21 , the second barrel 21 is slidably connected to the second piston plate 43 , and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com