Conveying device for oil well oil extraction

A conveying device and oil conveying technology, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of low efficiency and labor consumption, achieve flexible device adjustment, avoid device falling, and enhance the scope of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

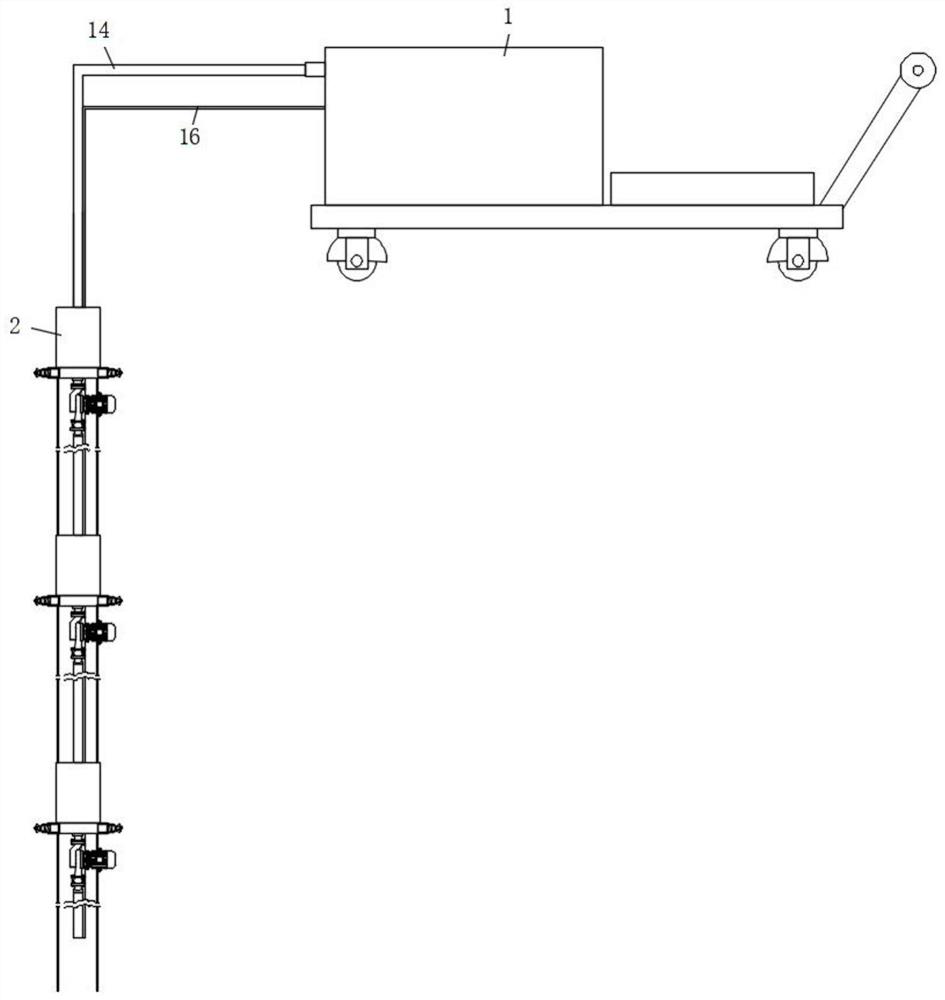

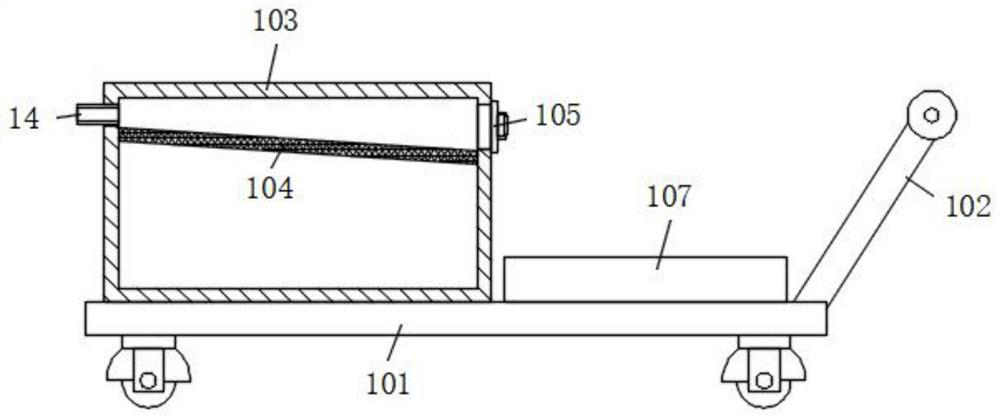

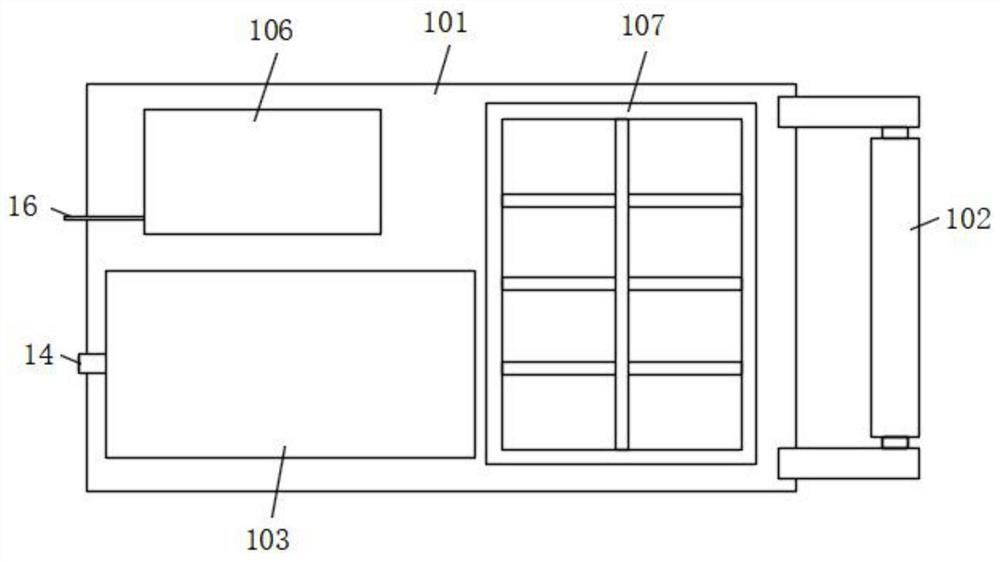

[0032] refer to Figure 1-5 , a delivery device for oil well production, comprising a push mechanism 1 and an oil delivery mechanism 2, a plurality of oil delivery mechanisms 2 are provided, the push mechanism 1 includes a push trolley 101, a push handle 102 is installed on one side of the push trolley 101, and the push trolley 101 An oil storage tank 103 is fixed at the front end of one side of the top surface, a filter screen 104 is fixed on the inner wall of the upper end of the oil storage tank 103, and a miscellaneous hole is opened on the upper side of the oil storage tank 103, and a sealing door body is installed on the outer wall of the miscellaneous hole through the hinge rotation 105, a generator 106 is also installed at the rear end of one side of the top surface of the push trolley 101, and a placement plate 107 is also fixed on the other side of the top surface of the push trolley 101. There are threaded holes, and the inner walls of the threaded holes are all fix...

Embodiment 2

[0035] Such as figure 1 and 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, two adjacent circular plates 3 in the two oil delivery mechanisms 2 are welded with fixed rings 17 at the ends close to each other, and the fixed rings 17 are each provided with two They are symmetrically distributed on both sides of the circular plate 3, and fixed ropes 18 are connected between two adjacent fixing rings 17 on the same side.

[0036] In this embodiment, two adjacent oil delivery mechanisms 2 are fixedly connected by the fixed rope 18, so that the fixing effect between the oil delivery mechanisms 2 is better, and the oil delivery mechanism 2 falls off and the device is prevented from falling.

Embodiment 3

[0038] Such as figure 2 and 3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the filter screen 104 is inclined downward from the outside of the pushing trolley 101 to the inside, and the sealing door 105 is located on the lower side of the filter screen 104 .

[0039] The placing tray 107 is arranged in a grid shape, and the outer wall of the push handle 102 is also fixed with a non-slip pad.

[0040] In this embodiment, the filter screen 104 is arranged at a slant, so that oil can be easily filtered through flow, and the efficiency of oil filtration is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com