Preparation method of nano calcium carbonate for single-component ms glue

A nano-calcium carbonate, single-component technology, applied in the direction of calcium carbonate/strontium/barium, adhesives, non-polymer adhesive additives, etc., can solve the problems of incompatibility between moisture and whiteness, high reinforcement and dispersibility, and oil absorption The amount can not be taken into account, etc., to achieve the effect of small oil absorption, large amount of filling, and easy dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

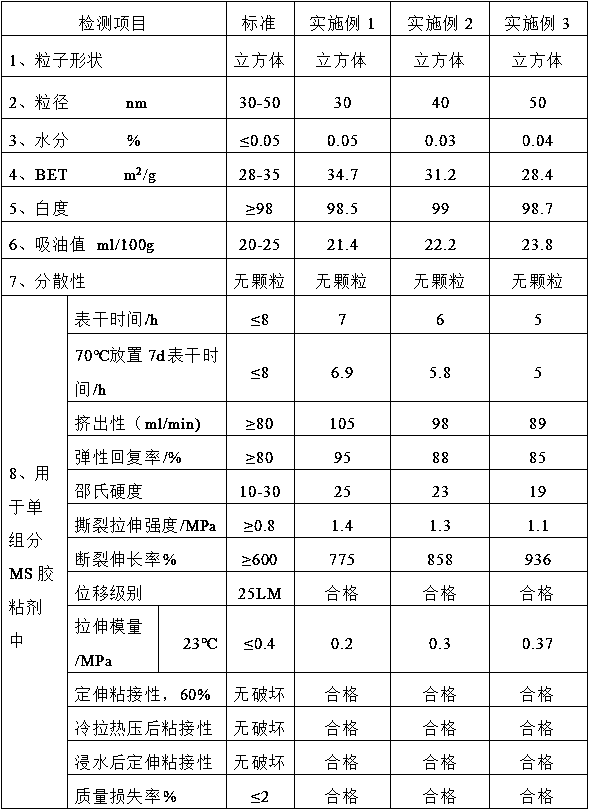

Examples

Embodiment 1

[0021] A preparation method of nanometer calcium carbonate for one-component MS glue includes the following steps:

[0022] 1) Take CaO whose activity is 420ml of HCl consumption, remove impurities and digest at high temperature to obtain Ca(OH) with a concentration of 15% and an activity of 30s 2 Suspension, stand aging, separate and remove impurities, and finally obtain 3% Ca(OH) 2 Seminal plasma suspension;

[0023] 2) Pump Ca(OH) into the supergravity reactor 2 The seminal plasma suspension is cooled to 5°C in circulation, and then CO is introduced 2 Kiln gas with a content of 80%, react for 5 minutes, and add crystal-type isolating agent when the conductivity drops sharply for the first time;

[0024] 3) Continue to pump Ca(OH) into the supergravity reactor 2 For seminal slurry, the pumping volume is twice that of the first pumping volume, and the temperature is circulated to 15℃ and CO is introduced 2 Kiln gas with a content of 30%, react for 30 minutes, stop the reaction when t...

Embodiment 2

[0029] A preparation method of nanometer calcium carbonate for one-component MS glue includes the following steps:

[0030] 1) Take CaO whose activity is 410ml of HCl consumption, remove impurities and digest at high temperature to obtain Ca(OH) with a concentration of 10% and an activity of 40s 2 Suspension, stand aging, separate and remove impurities, and finally get Ca(OH) with a concentration of 5% 2 Seminal plasma suspension;

[0031] 2) Pump Ca(OH) into the supergravity reactor 2 The seminal plasma suspension is cooled to 10°C in circulation, and then CO is introduced 2 Kiln gas with a content of 70%, react for 10 minutes, and add crystal-type isolating agent when the conductivity drops sharply for the first time;

[0032] 3) Continue to pump Ca(OH) into the supergravity reactor 2 For seminal slurry, the pumping volume is 4 times that of the first pumping volume, and the temperature is reduced to 17°C in circulation, and CO is introduced 2 Kiln gas with a content of 40%, react f...

Embodiment 3

[0037] A preparation method of nanometer calcium carbonate for one-component MS glue includes the following steps:

[0038] 1) Take the CaO whose activity is 400ml HCl consumption, remove impurities and digest at high temperature to obtain Ca(OH) with a concentration of 20% and an activity of 50s 2 Suspension, stand aging, separate and remove impurities, and finally obtain Ca(OH) with a concentration of 8% 2 Seminal plasma suspension;

[0039] 2) Pump Ca(OH) into the supergravity reactor 2 The seminal plasma suspension is cooled to 15°C cyclically, and then CO is introduced 2 The kiln gas with a content of 60%, react for 7 minutes, and add the crystalline isolating agent when the conductivity drops significantly for the first time;

[0040] 3) Continue to pump Ca(OH) into the supergravity reactor 2 Seminal slurry suspension, the pumping volume is 5 times the first pumping volume, and the temperature is cooled to 25°C in circulation, and CO is introduced 2 Kiln gas with a content of 38...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com