A large displacement pump combined with a vane pump and a gear pump

A vane pump with large displacement technology, applied in pumps, rotary piston pumps, rotary piston machines, etc., can solve problems such as poor sealing of working volume, unbalanced radial force, and increased noise of gear pumps, and achieve Low noise, easy processing, high pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the drawings and embodiments.

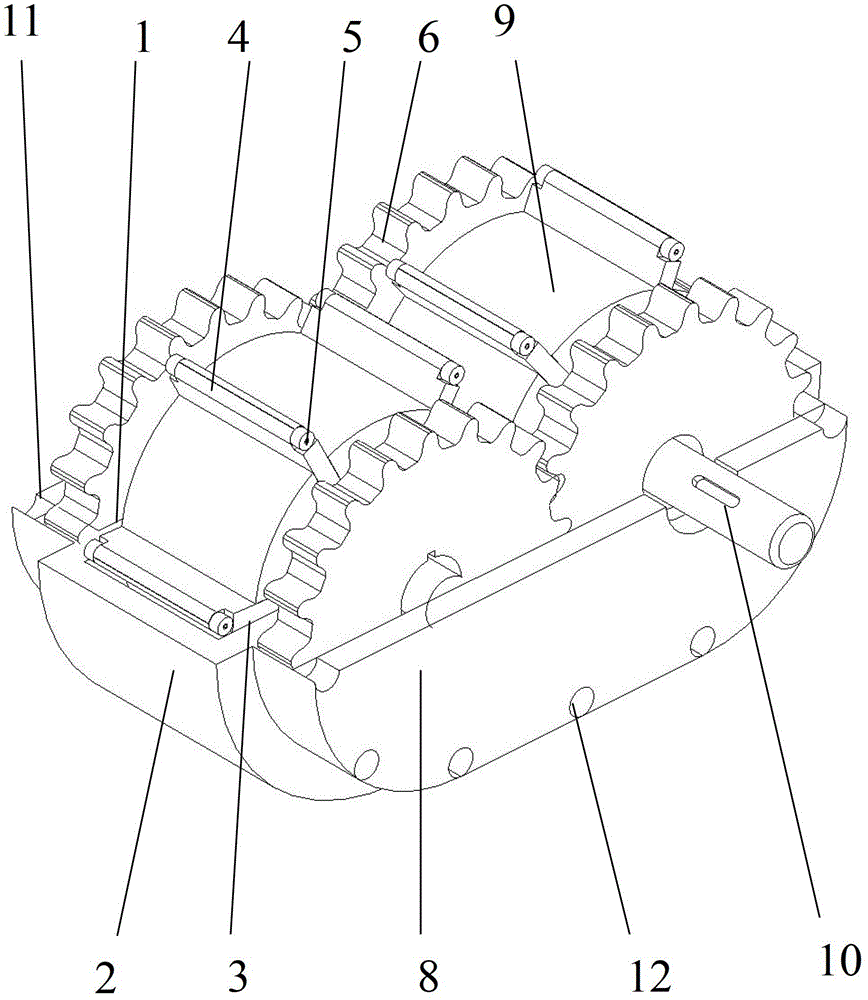

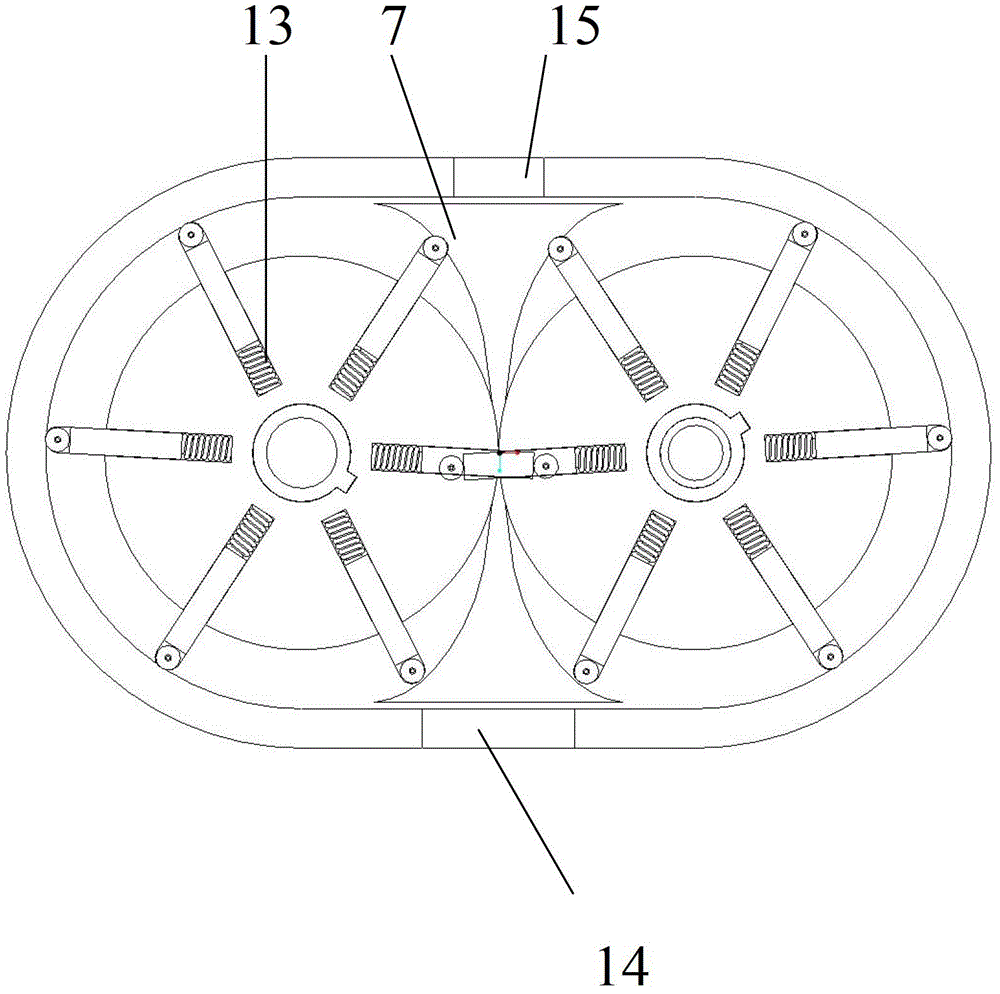

[0012] In a structure of a large displacement pump combining a vane pump and a gear pump, a pump body rear cover 1; a pump body 2; a pump body front cover 3; a blade 4; a roller 5; a gear 6; a guide plate 7; Cover 8; rotor 9; rotating shaft 10; gear rear cover 11; bolt 12; spring 13; oil inlet 14; oil outlet 15. The top and bottom of the pump body 2 are respectively provided with an oil outlet 15 and an oil inlet 14, The pump body 2 is provided with two rotors 9 circumscribed on the outer surface. The rotors 9 are sleeved on the rotating shaft 10. Each rotor 9 has six slides. The slides are equipped with blades 4 and are installed at the roots of the blades 4. There is a spring 13, and the top ends of the blade 4 are equipped with a roller 5 respectively. When the roller 5 is in contact with the guide plate 7 and guided by the guide plate 7, the blade 4 is returned to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com