a vane pump

A vane pump and vane technology, which is applied in the field of hydraulic pumps, can solve problems such as cavitation caused by air suction, insufficient oil absorption, and influence on stable work, and achieve the effects of solving insufficient self-priming ability, avoiding cavitation, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

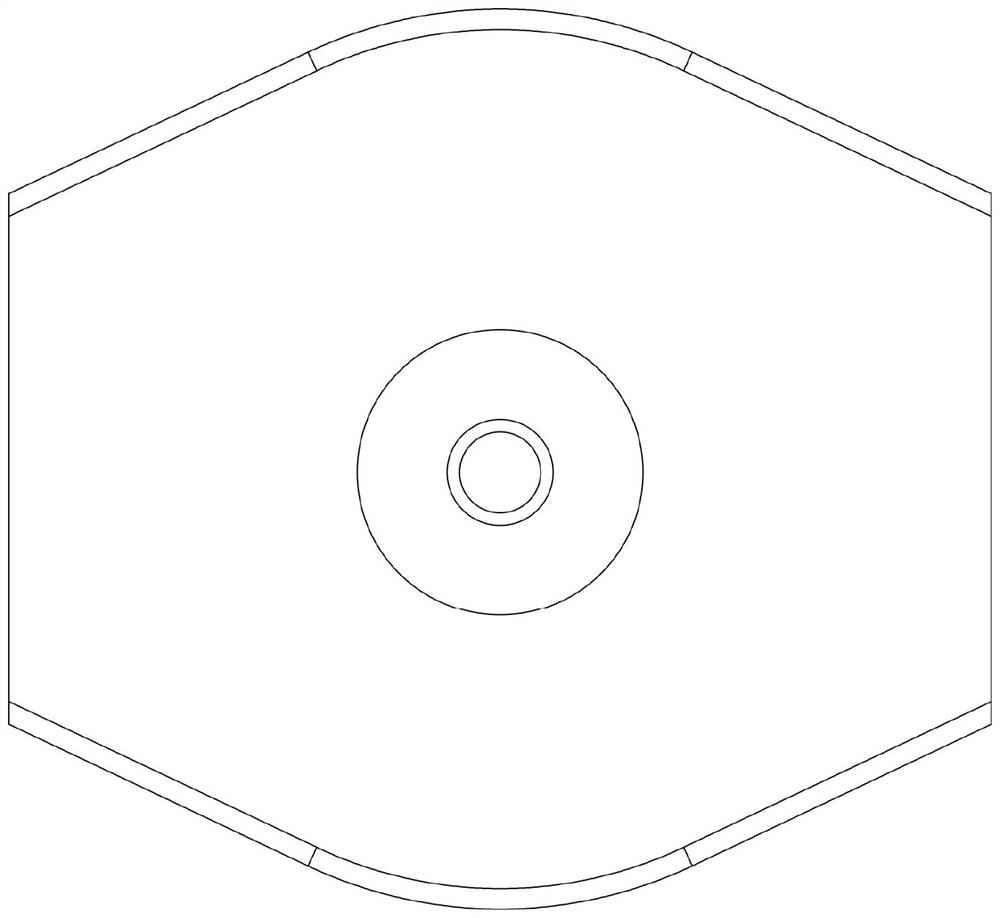

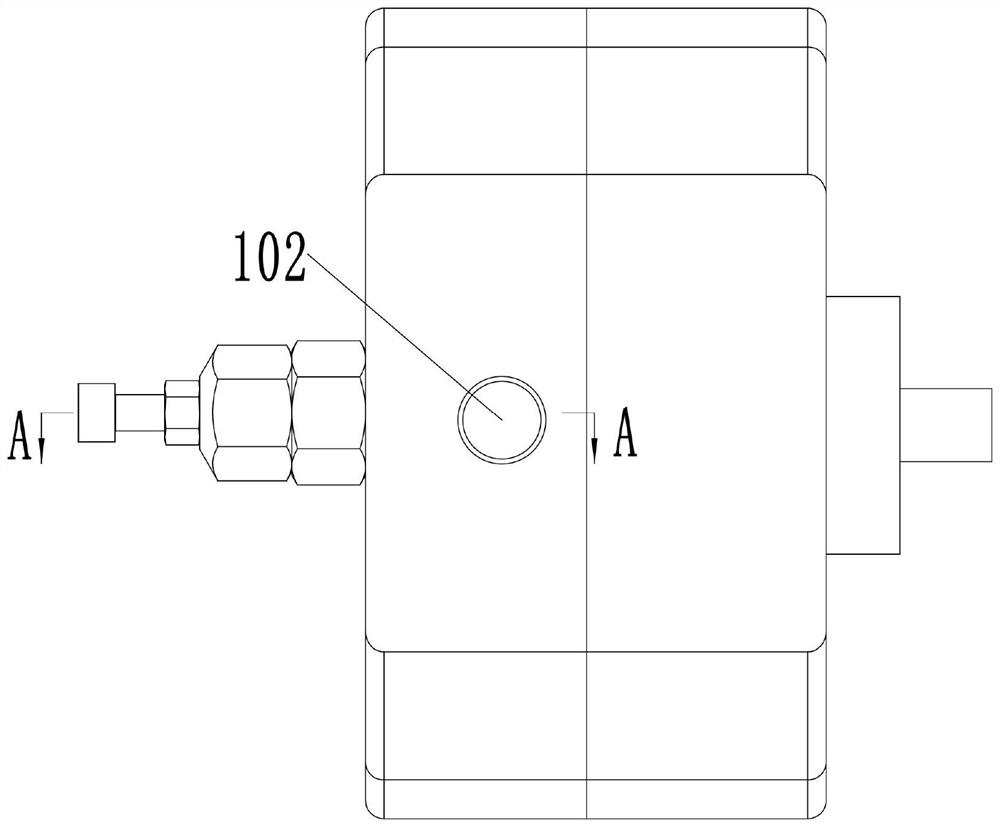

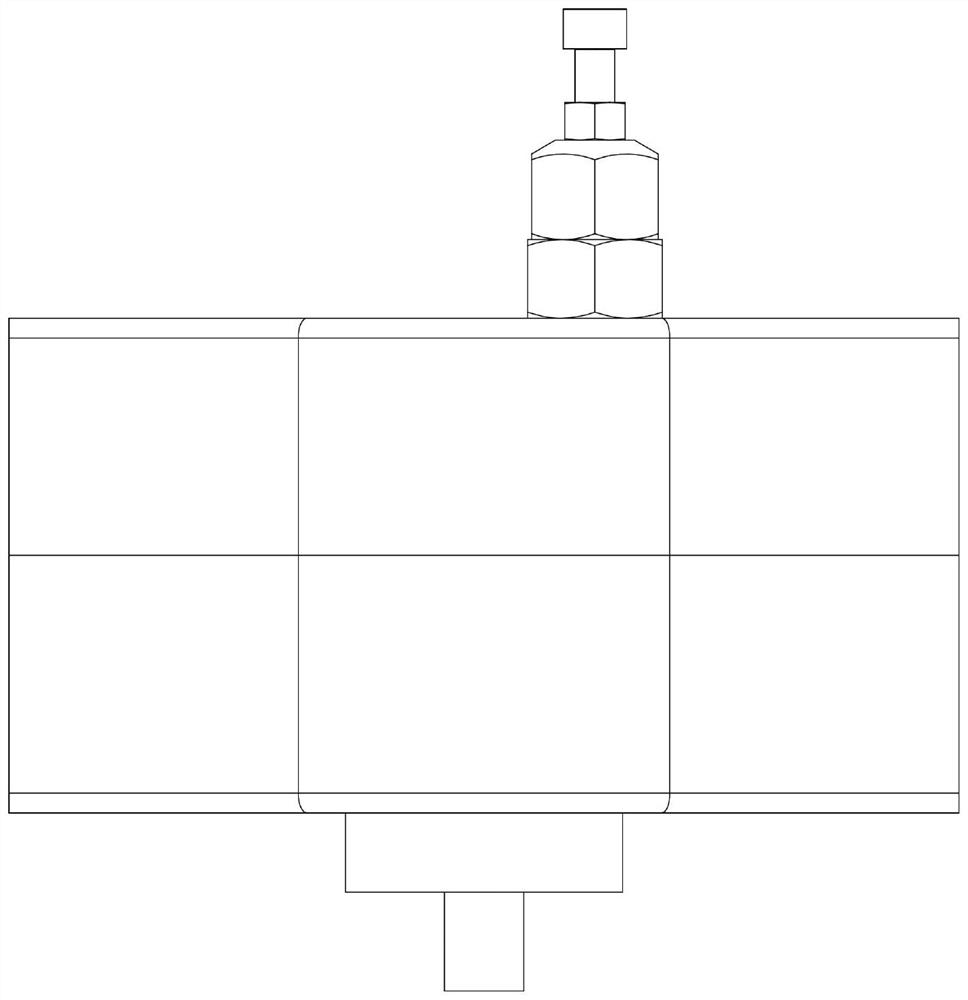

[0027] see Figure 1-12 As shown, a vane pump includes a pump casing 7, and an end cover 1 arranged at the opening of the pump casing 7; a rotating shaft 8 is rotatably connected between the end cover 1 and the pump casing 7, and the rotating shaft 8 is located at the end cover 1 and the eccentric position of the pump casing 7, one end of the rotating shaft 8 protrudes from the pump casing 7; a stator 3 is fixedly installed in the pump casing 7, and the stator 3 is coaxially arranged with the pump casing 7; A blade chamber 301 is provided; a rotor 4 is rotatably connected to the blade chamber 301, and the rotor 4 is coaxially arranged with the stator 3; A blade 5 is slidably connected in the connection groove 401; a gear chamber 403 is provided at the center of the rotor 4; a protruding tooth 402 is provided on the inner peripheral side wall of the gear chamber 403, and the rotating shaft 8 is fixedly installed with a protruding The internal gear 6 meshed with the teeth 402, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com