Self-adaptive closed hydraulic oil tank

A hydraulic oil tank, self-adaptive technology, applied in the direction of oil supply tank device, fluid pressure actuation device, fluid pressure actuation system components, etc., can solve the problem of affecting the normal operation of the hydraulic system, increasing leakage, hydraulic pump cavitation, etc. problem, to achieve the effect of solving insufficient self-priming capacity, flexible layout, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

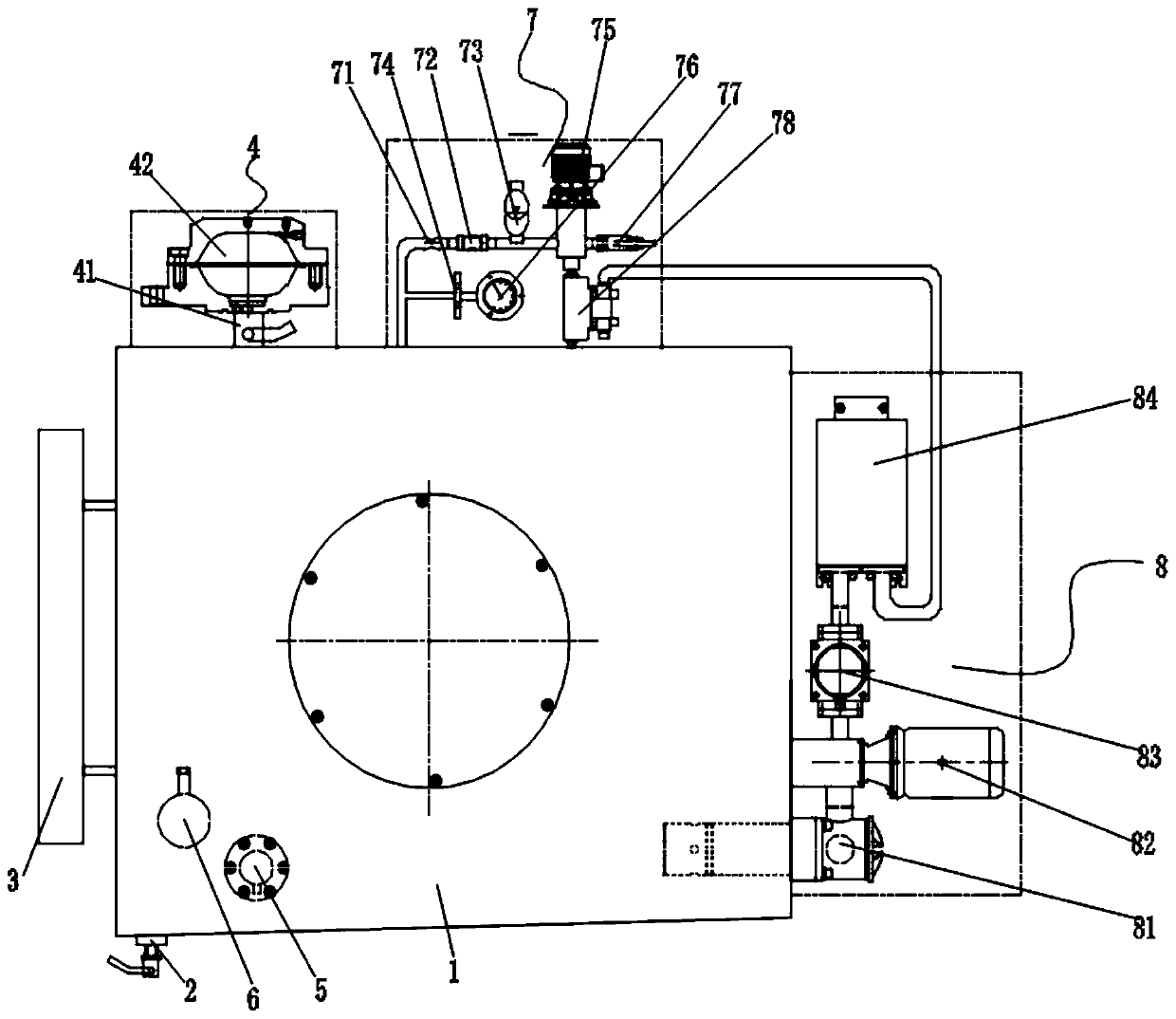

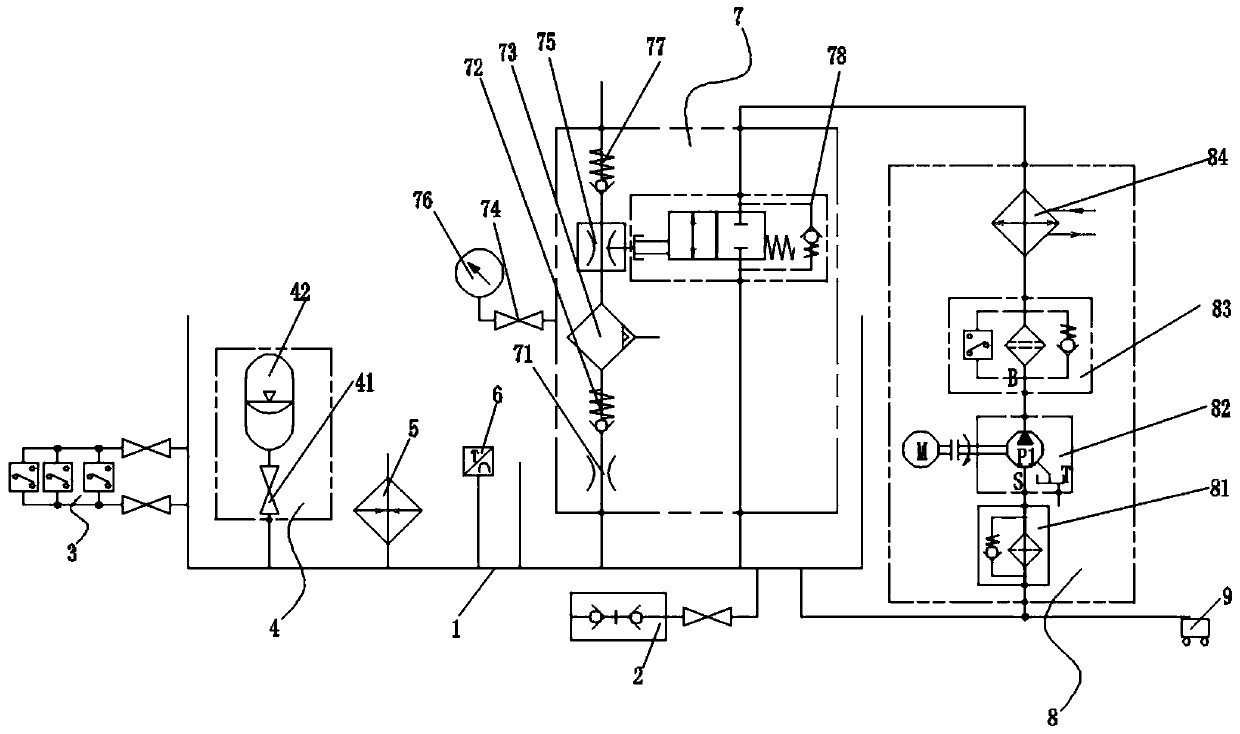

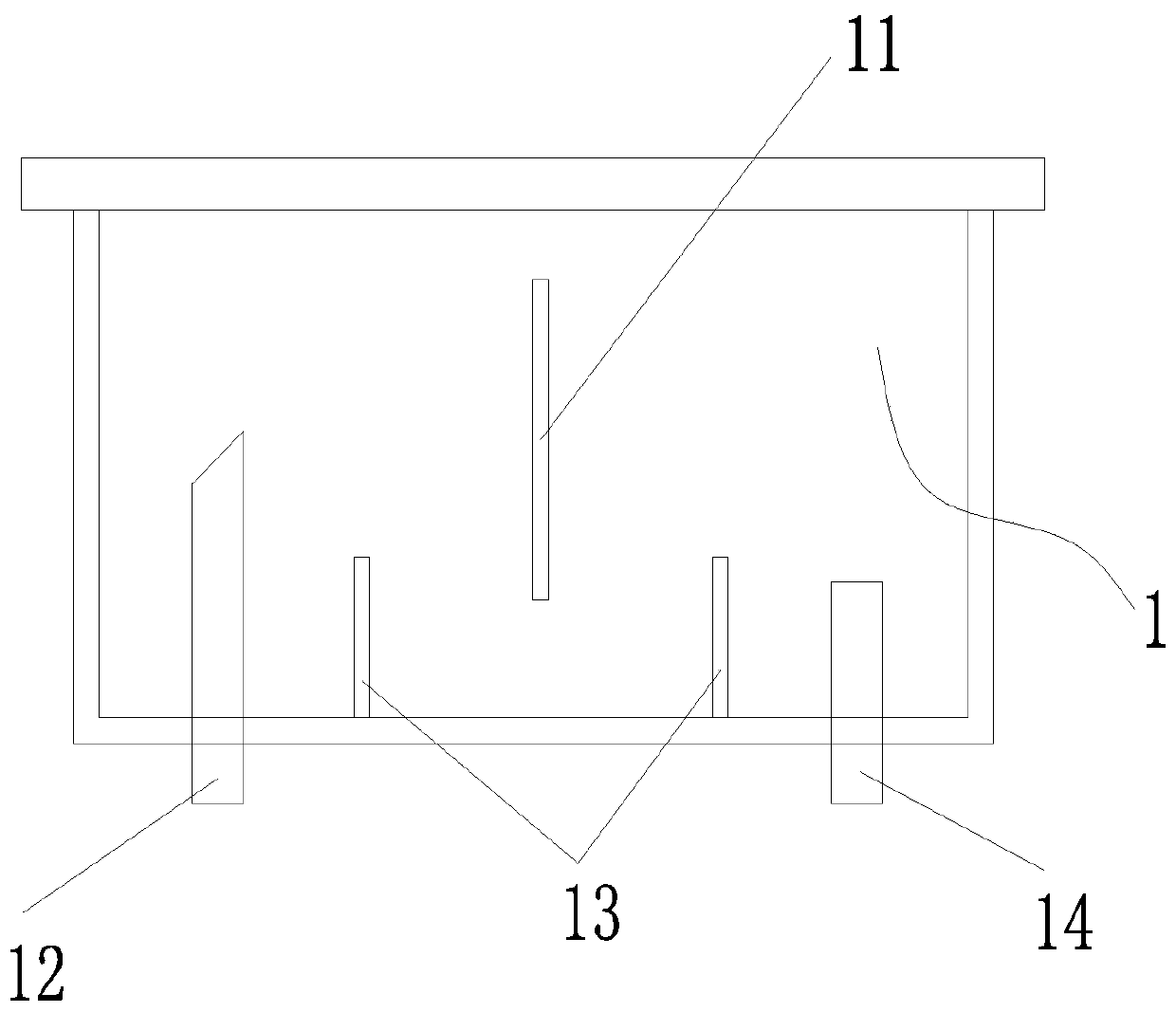

[0022] figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a structural schematic diagram of the hydraulic system of the present invention; image 3 It is a schematic diagram of the internal arrangement structure of the box body of the present invention; Figure 4 It is a schematic diagram when the vacuum generator of the present invention runs downward; Figure 5 It is a schematic diagram of the upward operation of the vacuum generator of the present invention; as shown in the figure; an adaptive closed hydraulic oil tank includes a fuel tank body 1, a liquid-gas isolation mechanism 4 arranged on the fuel tank body 1, and a liquid-gas isolation mechanism 4 arranged on the top of the fuel tank body 1 The degassing and dehydrating mechanism 7 and the filtration and cooling cycle mechanism 8 arranged on the fuel tank body 1; the degassing and dehydrating mechanism includes a damping channel 71 communicated with the inside of the fuel tank bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com