Hanging bag bag making machine

A bag-making machine and bag-making technology, which is applied in bag-making operations, flexible container manufacturing, paper/cardboard containers, etc., can solve the problems of uneven wrinkles, easy confusion, and increased labor intensity of workers, so as to maintain flatness and ensure cleansing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

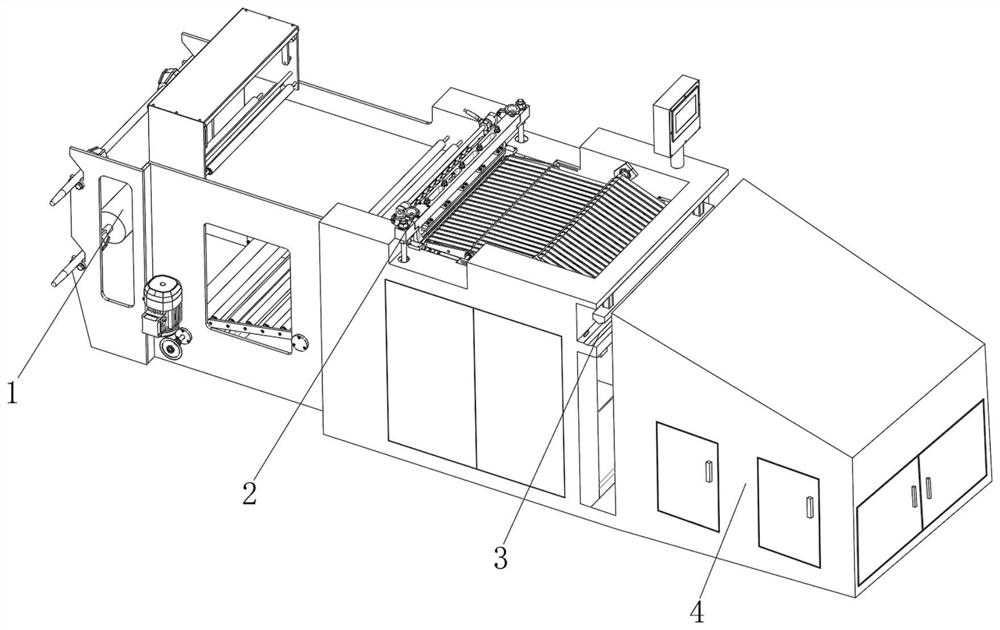

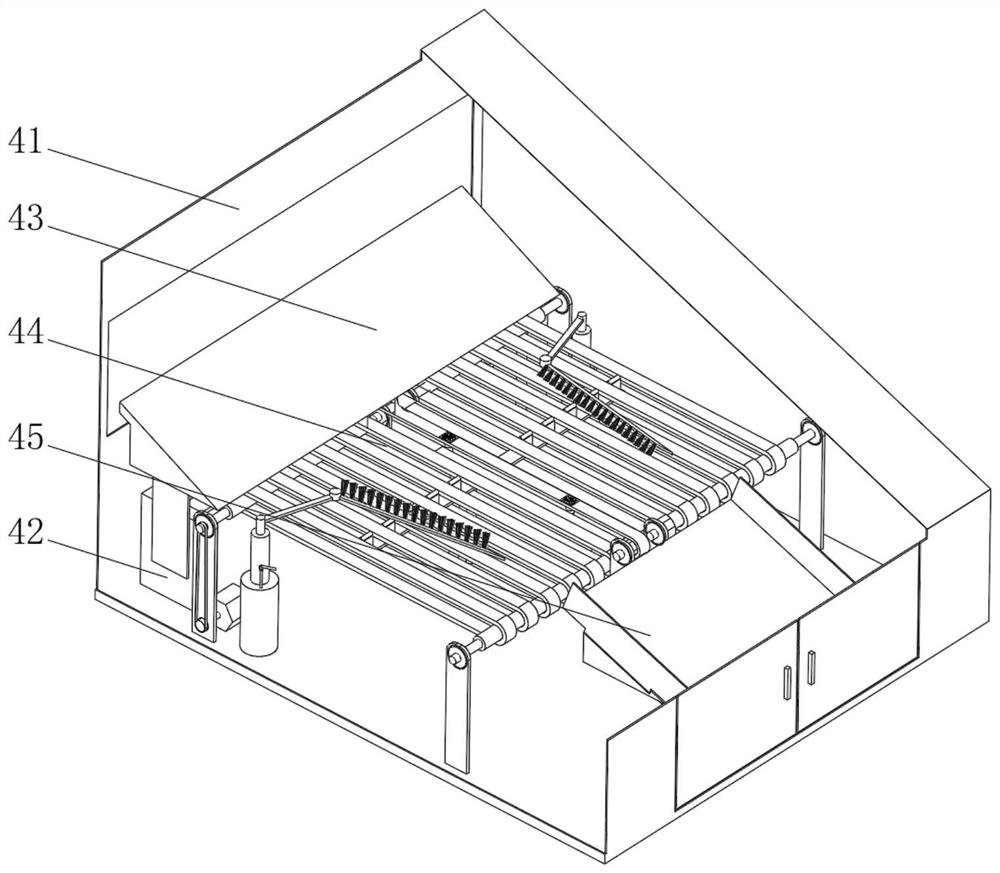

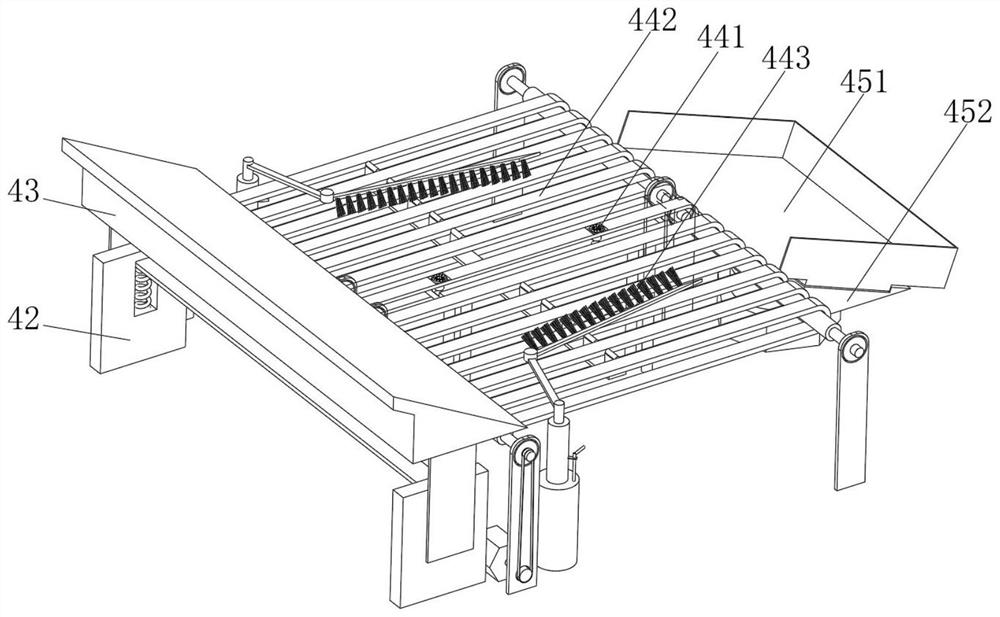

[0040] see Figure 1-6 , the present invention provides a technical solution: hanging bag making machine, including feeding device 1, sealing device 2, cutter control device 3 and packaging device 4, feeding device 1, sealing device 2, cutter control device 3 and packaging device 4. Install in order from left to right. The packaging device 4 includes a packaging case 41. The outside of the packaging case 41 is fixedly installed on the right side of the cutter control device 3. The inside of the packaging case 41 is fixedly installed with a slide plate 43 through a support frame 42 arranged on the bottom inner wall. , the front side of the slide plate 43 is provided with a finishing mechanism 44, and the finishing mechanism 44 is provided with a collection mechanism 45 away from the side of the slide plate 43. The finishing mechanism 44 includes an adsorption mechanism 441, and the inner wall of the adsorption mechanism 441 is equipped with a conveying mechanism 442 through a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com