Novel yarn feeding mechanism and application thereof

A yarn feeding mechanism and yarn feeding technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of technical talents, high technical requirements, and cumbersome operations in fabric production companies, so as to facilitate maintenance and reduce Technical requirements, the effect of ensuring the original precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

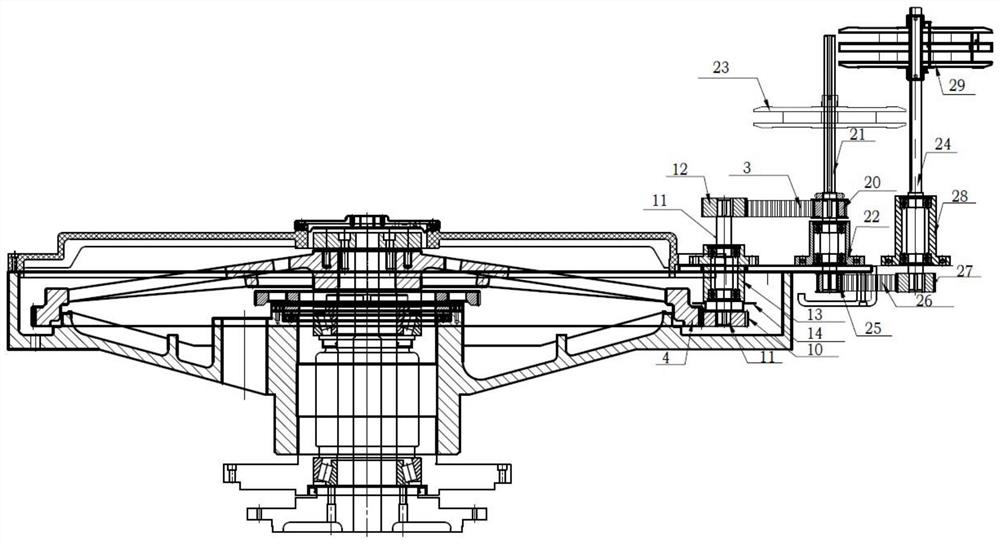

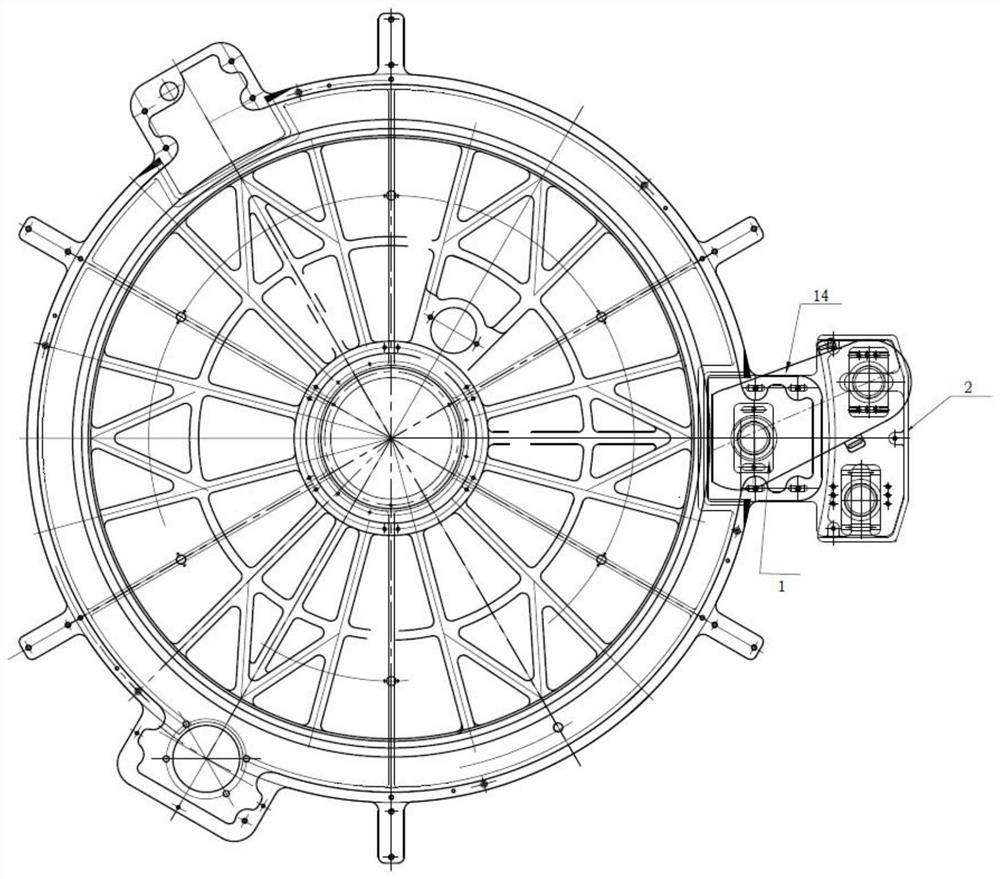

[0028] As a first aspect of the embodiment, a novel yarn feeding mechanism is proposed, such as Figure 1-2 As shown, it includes a fixed transmission assembly 1, a yarn feeding assembly 2, and a first connection assembly 3 that is in transmission connection with the fixed transmission assembly 1 and the yarn feeding assembly 2; wherein,

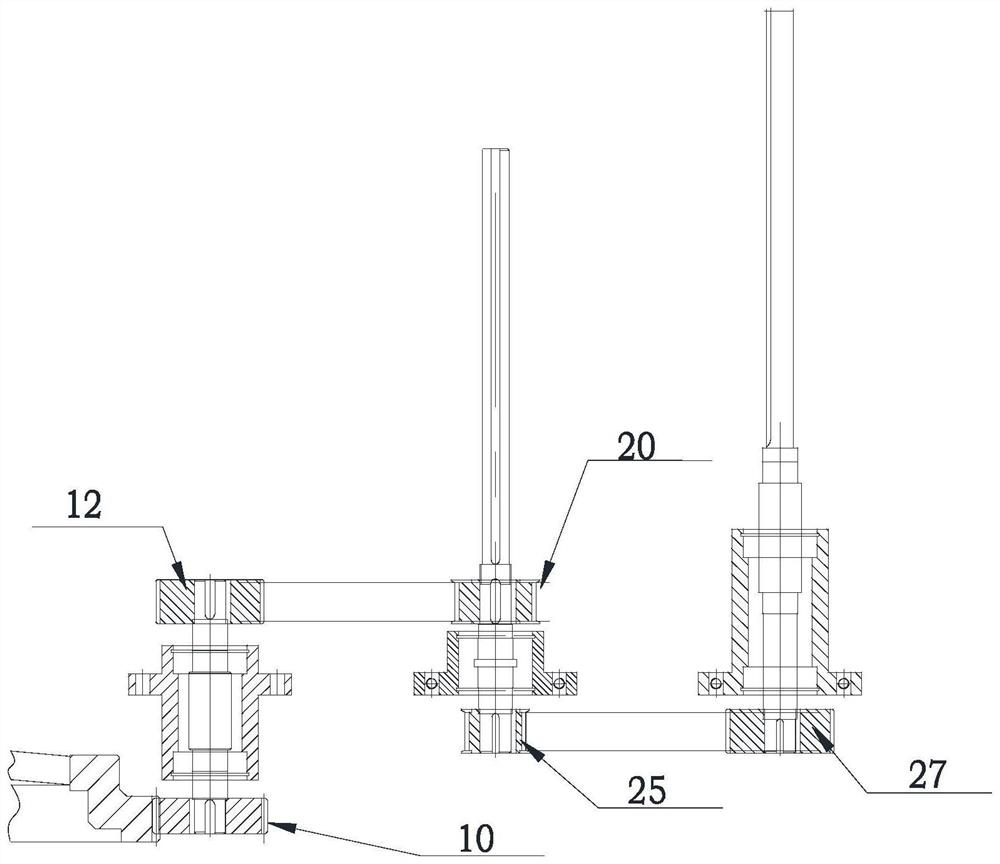

[0029] The fixed transmission assembly 1 includes a nylon gear 10 connected with the big tripod gear 4 of the circular weft knitting machine and a first synchronous gear 12 connected with the transmission of the first connection assembly 3, the nylon gear 10 and the first synchronous gear The gear 12 is connected through the yarn feeding transmission shaft 11, and the yarn feeding transmission shaft 11 is fixed on the circular weft knitting machine through the yarn feeding transmission bearing seat 13;

[0030] The first connecting component 3 is a synchronous belt;

[0031] The yarn feeding assembly 2 includes a second synchronous gear 20 ...

Embodiment 2

[0044] This embodiment presents a new type of yarn feeding structure with a single yarn feeding shaft: it includes a fixed transmission assembly 1, a yarn feeding assembly 2 and a first connecting assembly that is in transmission connection with the fixed transmission assembly 1 and the yarn feeding assembly 2 3; among them,

[0045] The fixed transmission assembly 1 includes a nylon gear 10 connected with the big tripod gear 4 of the circular weft knitting machine and a first synchronous gear 12 connected with the transmission of the first connection assembly 3, the nylon gear 10 and the first synchronous gear The gear 12 is connected through the yarn feeding transmission shaft 11, and the yarn feeding transmission shaft 11 is fixed on the circular weft knitting machine through the yarn feeding transmission bearing seat 13;

[0046] The first connecting component 3 is a synchronous belt;

[0047] The yarn feeding assembly 2 includes a second synchronous gear 20 connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com