Adjustable anti-settling well lid for municipal engineering

An adjustable, anti-settling technology, applied in hydraulic engineering, infrastructure engineering, artificial islands, etc., can solve problems such as easy settlement of manhole covers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

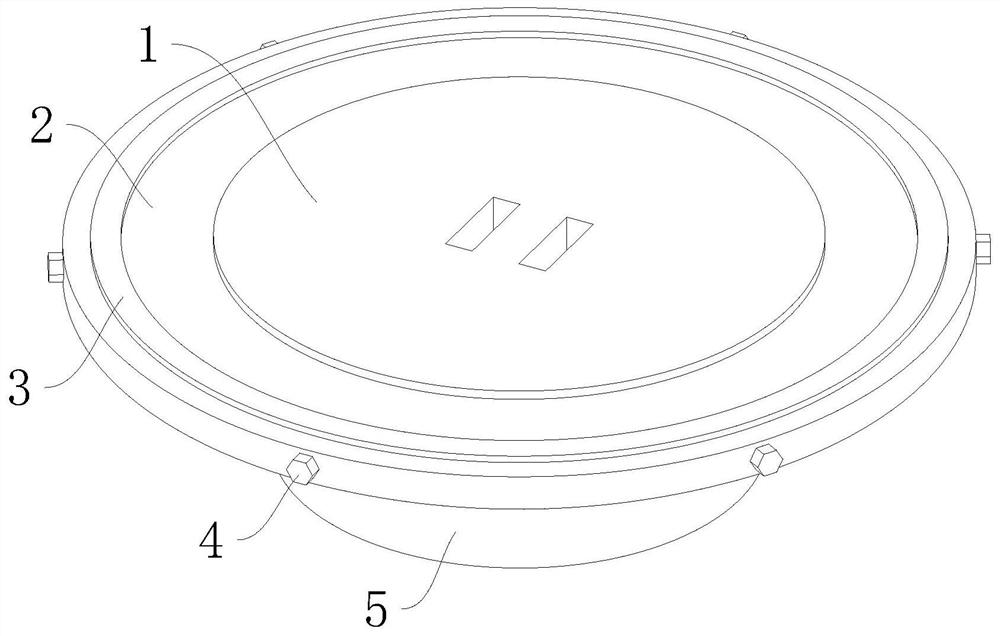

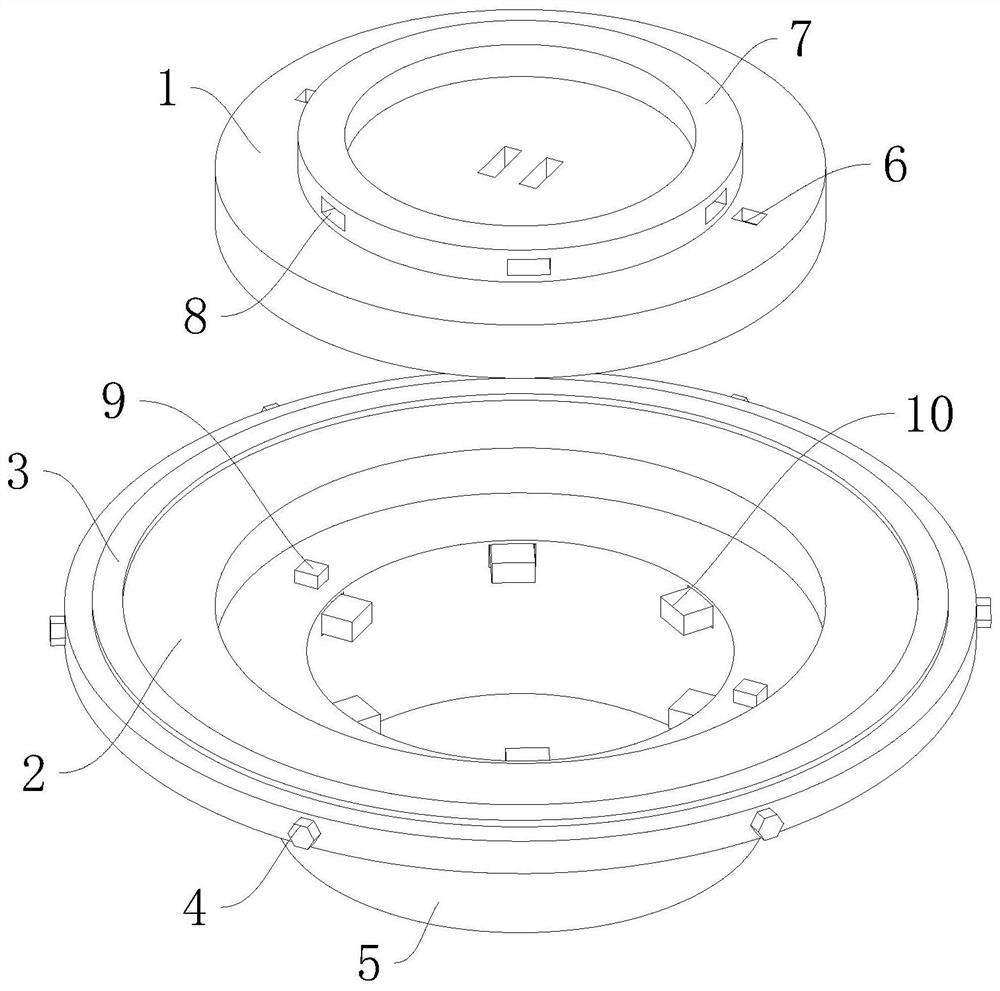

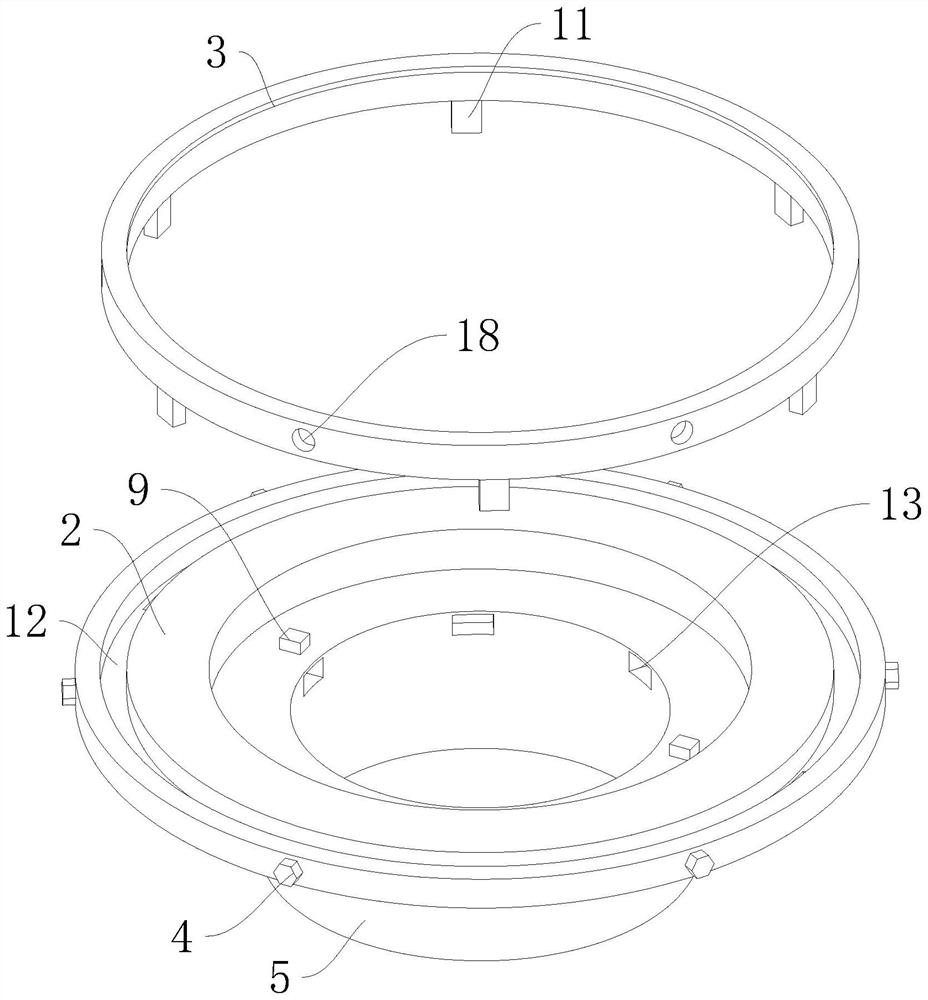

[0024] refer to Figure 1-5 , an adjustable anti-settling manhole cover used in municipal engineering, comprising a manhole cover body 1, a support seat 2 is installed at the bottom of the manhole cover body 1, a receiving seat 5 is installed at the bottom of the support seat 2, and the outside of the top of the receiving seat 5 is evenly installed along the circumferential direction. A fixed frame 15, the inner side of the top of the receiving seat 5 is evenly provided with a plurality of chute 13 along the circumferential direction, the position of the chute 13 corresponds to the position of the fixed frame 15, and the cross-sectional size of the fixed frame 15 is the same as that of the chute 13 The size matches, and the limit plate 10 is slidably installed inside the fixed frame 15, and the limit mechanism is installed between the well cover body 1 and the limit plate 10. The limit mechanism includes a limit ring 7 and a limit groove 8, and the limit ring 7 is installed on ...

Embodiment 2

[0028] refer to Figure 2-4 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that positioning blocks 9 are installed on both sides of the top of the receiving seat 5, positioning grooves 6 are opened on both sides of the bottom of the well cover body 1, and the positioning grooves 6 The position corresponds to the position of the positioning block 9, and the size of the positioning block 9 matches the size of the positioning groove 6. Through the mutual clamping of the positioning block 9 and the positioning groove 6, the alignment of the well cover body 1 can be completed when the well cover body 1 is installed. The preliminary positioning of the well cover body 1 facilitates the subsequent adjustment operation of the position of the well cover body 1, reduces the installation difficulty of the well cover body 1, and can improve the installation stability of the well cover body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com