Decoupling mechanism for large-displacement vibration test and test device

A technology of vibration test and large displacement, which is applied in the direction of vibration test, measuring device, machine/structural component testing, etc. It can solve the problem that the electrodynamic vibration table cannot meet the requirements, the test cannot be carried out, and the development and exploration of large displacement vibration test technology are limited, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

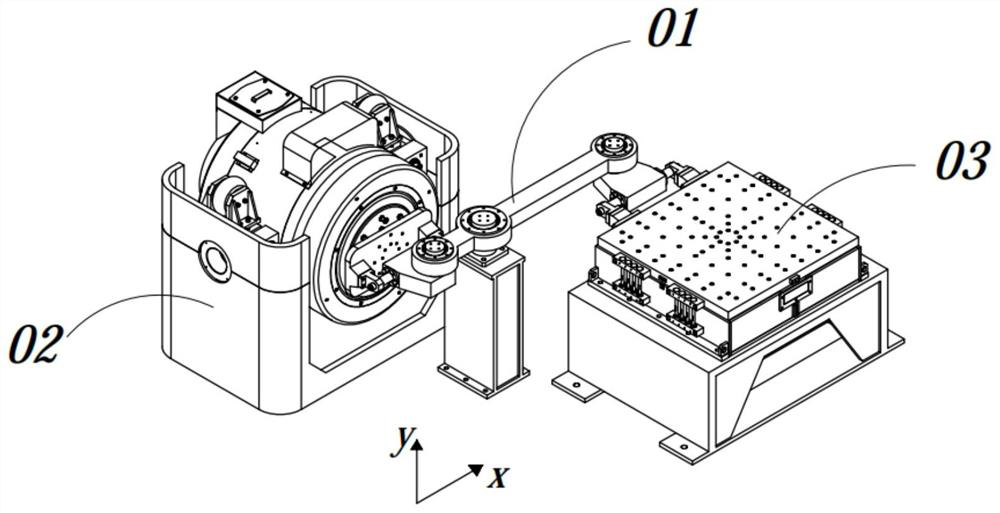

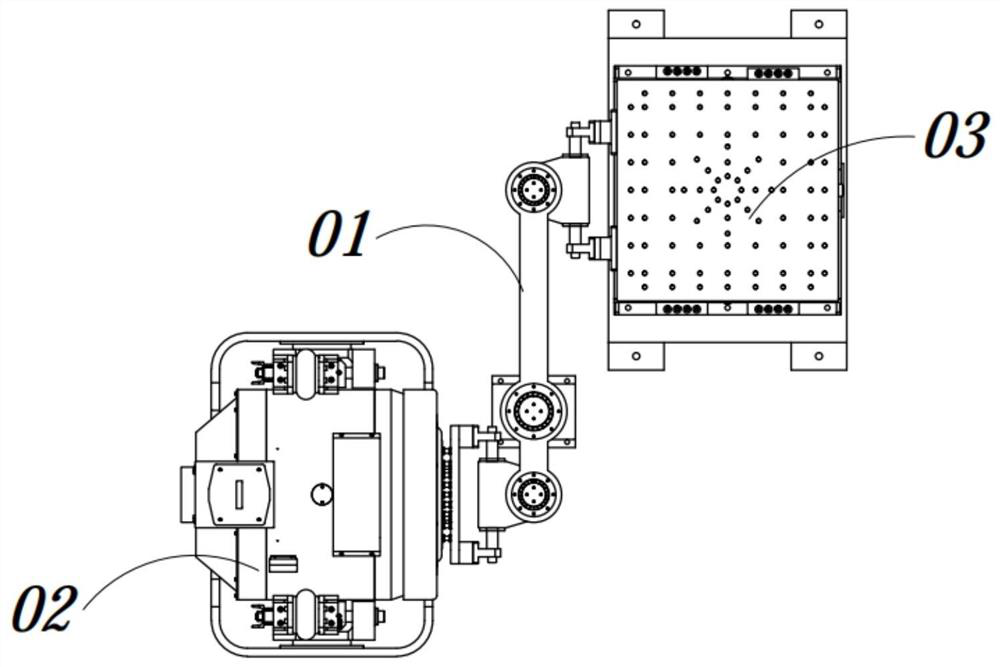

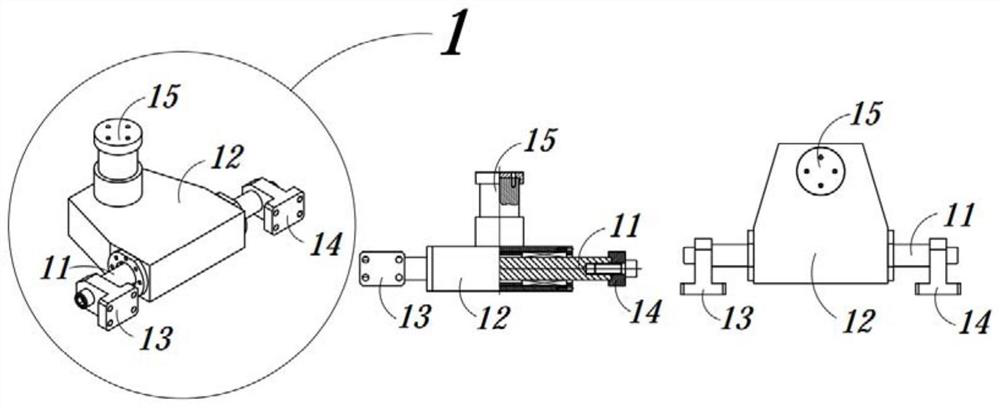

[0042] This embodiment provides a decoupling mechanism for large displacement vibration tests, including a first transmission decoupling assembly 1, a rotation amplification assembly 3 and a second transmission decoupling assembly 2, such as Figure 1 ~ Figure 2 shown.

[0043] Such as Figure 7 As shown, the rotation amplification assembly 3 includes a support 31 and a transmission rod 32. The third connecting shaft 33 is arranged on the top of the support 31. The direction of the axis of the third connecting shaft 33 extends along the y-axis. The transmission rod 32 There is a third annular hole through the third connecting shaft 33 on the top, the transmission rod 32 is connected to the third connecting shaft 33 through the third annular hole, and the first end of the transmission rod 32 is provided with The first ring hole, the second end of the transmission rod 32 is provided with a second ring hole; preferably, the distance from the axis of the third connecting shaft 33...

Embodiment 2

[0050] This embodiment provides a kind of vibration test device for large displacement vibration test, see Figure 1 ~ Figure 2 , including the vibrator 02, the slide assembly 03 and the decoupling mechanism provided by Embodiment 1. Preferably, the vibrator 02 is provided with a first adapter block 4, such as Figure 8As shown, the first adapter block 4 is provided with a number of screw holes for fixing the first adapter block 4 to the vibrator 02, and the first adapter block 4 is also provided for fixing the first The first protrusion of the fixed block 13 and the second protrusion used to fix the second fixed block 14 are also provided with several screw holes respectively on the first protrusion and the second protrusion; 03 is provided with a second transfer block 5, such as Figure 9 As shown, a number of screw holes are provided on the second adapter block 5 for fixing the second adapter block 5 to the slide assembly 03, and there are also provided on the second adap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com