Cable automatic calibration and automatic compensation method of comprehensive detection equipment

A comprehensive detection and automatic calibration technology, applied in the direction of measuring devices, measuring electrical variables, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the specific implementation modes of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

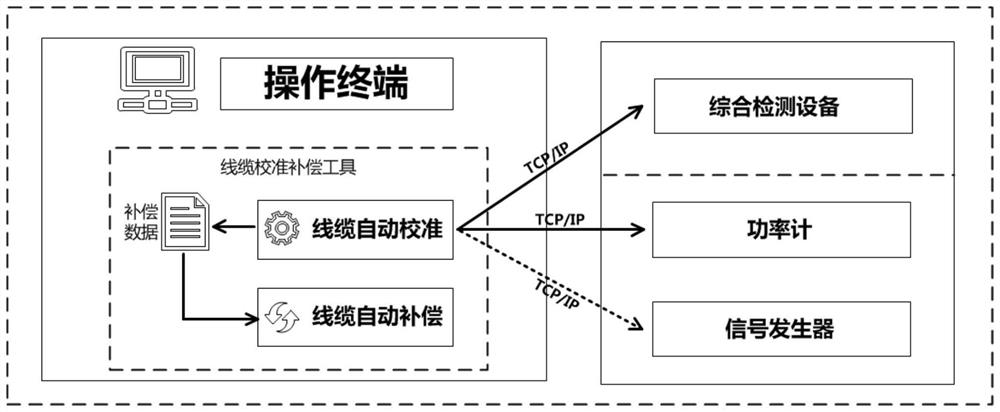

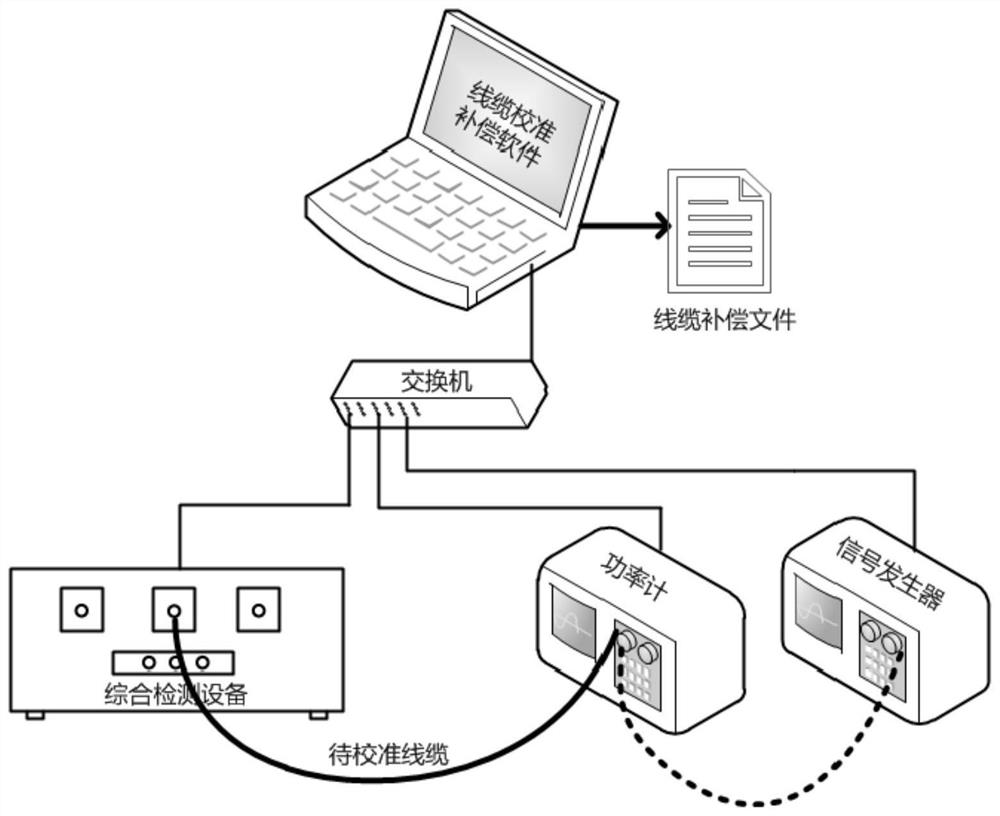

[0027] Such as Figure 1-2 As shown in the figure, a cable automatic calibration and automatic compensation method of comprehensive detection equipment uses the operation terminal, comprehensive detection equipment, power meter, signal generator and switch to automatically calibrate and automatically compensate the cable; wherein, the operation terminal passes The switch is connected with comprehensive testing equipment, power meter and signal generator;

[0028] Include the following steps:

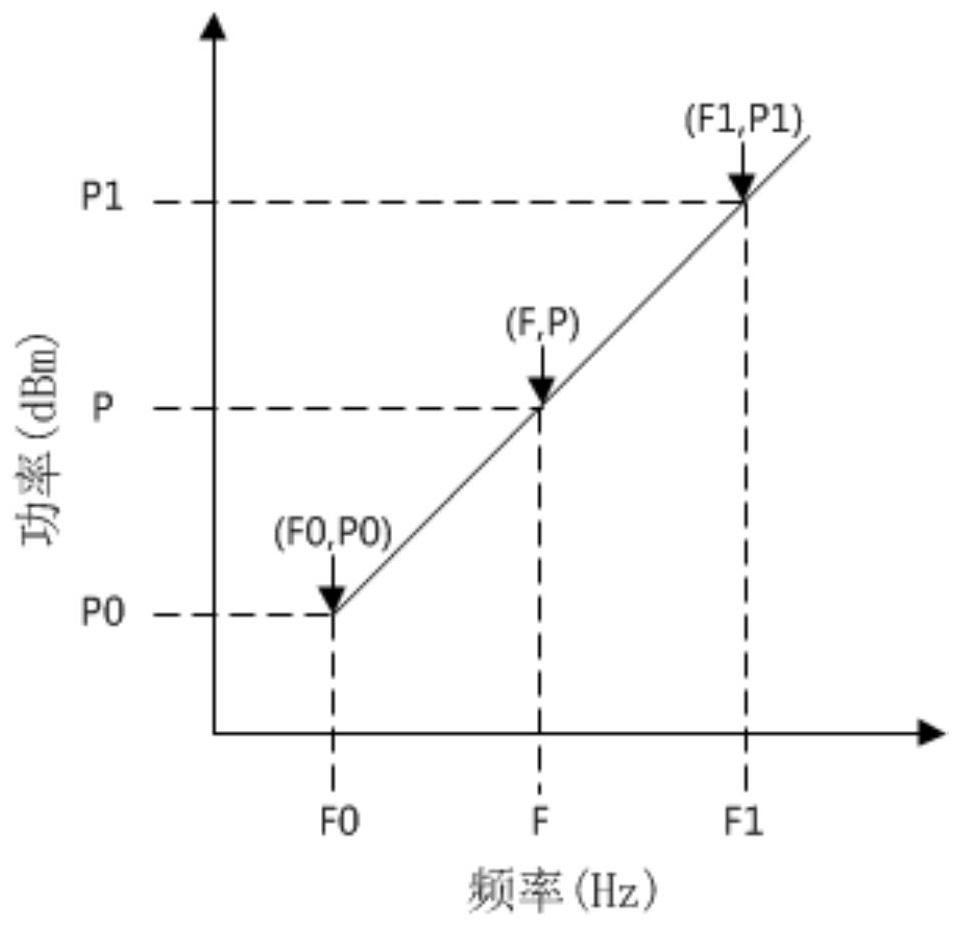

[0029] S1. Connect the power meter probe to the output port of the signal generator. The signal generator selects the built-in 20MHz-18GHz frequency band signal generator of the comprehensive testing equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com