Automatic model compounding analysis system and method for building structure

A technology of building structure and analysis method, applied in 3D modeling, image analysis, design optimization/simulation, etc., which can solve problems such as low work efficiency and inability to control the accuracy of quality inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

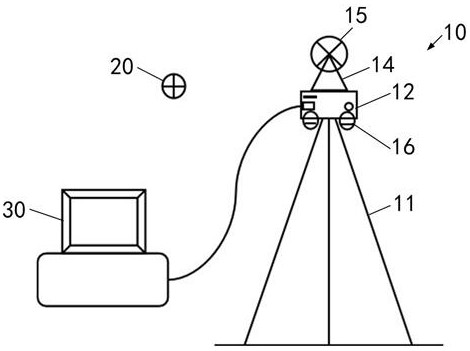

[0024] combine figure 1 Illustrate the building structure automatic mold closing analysis system of the present invention, it comprises: digital scanning device 10, target 20 and workstation 30, digital scanning device 10 and target 20 are arranged in the space to be detected on the construction site, and target center point and The actual reference points of the construction site control network are located on the same vertical line, and the digital scanning devices 10 are respectively connected to the workstations 30 by communication. Among them, the target 20 is provided with a circular mark of black and white color blocks, and has a clearly identifiable central point.

[0025] The building structure automatic mold closing analysis system of the present invention includes a digital scanning device 10, a target 20, and a workstation 30. The digital scanning device 10 and the target 20 are arranged in the space to be detected, and the center point of the target is connected to...

Embodiment 2

[0030] combine figure 1 Illustrate the building structure automatic mold closing analysis method of the present invention, the steps are as follows:

[0031] S1: According to the coordinate system of the building structure design model, lay out the control network in the space to be tested on the construction site, and set at least three actual reference points that are not on the same straight line at the key positions of the control network;

[0032]S2: On-site layout of the building structure automatic mold closing analysis system as described in Example 1, place a target 20 at the position of each actual reference point, and the center point of the target and the actual reference point of the construction site control network are located at On the same vertical line, the digital scanning device 10 scans the surface coordinates of the space to be detected and transmits them to the data storage module of the workstation 30. The data reading module acquires the scanned data, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap